Animal fat crushing and dicing device based on linkage

An animal fat and linkage technology, applied in grain processing, raw material extrusion granulation, etc., can solve the problems of low crushing efficiency, long crushing time, multiple oil filtration, etc., to reduce the number of filtration times, improve crushing efficiency and The effect of crushing timeliness and high market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

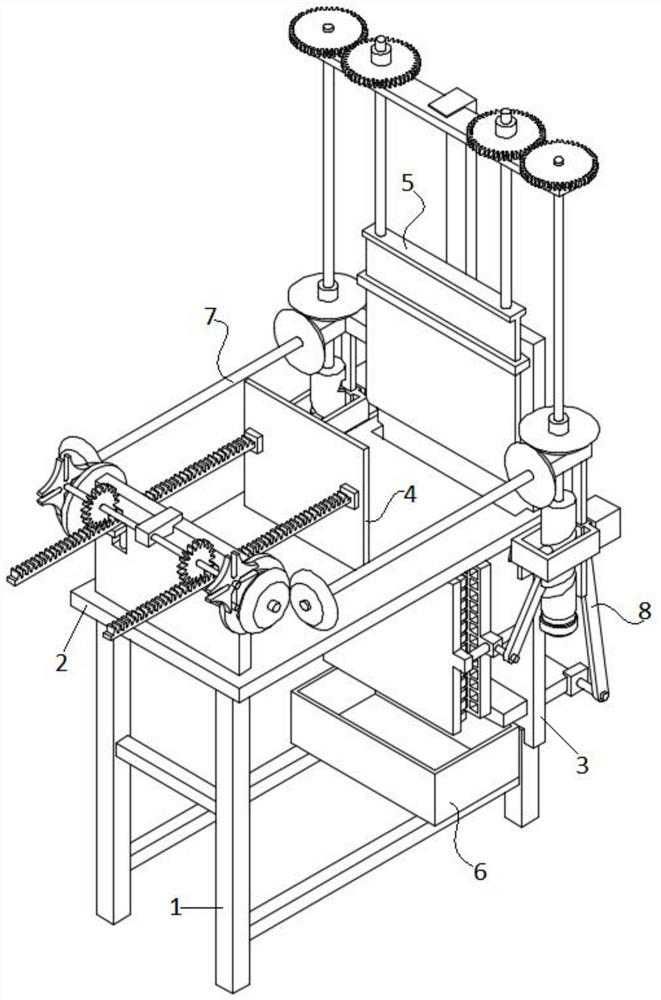

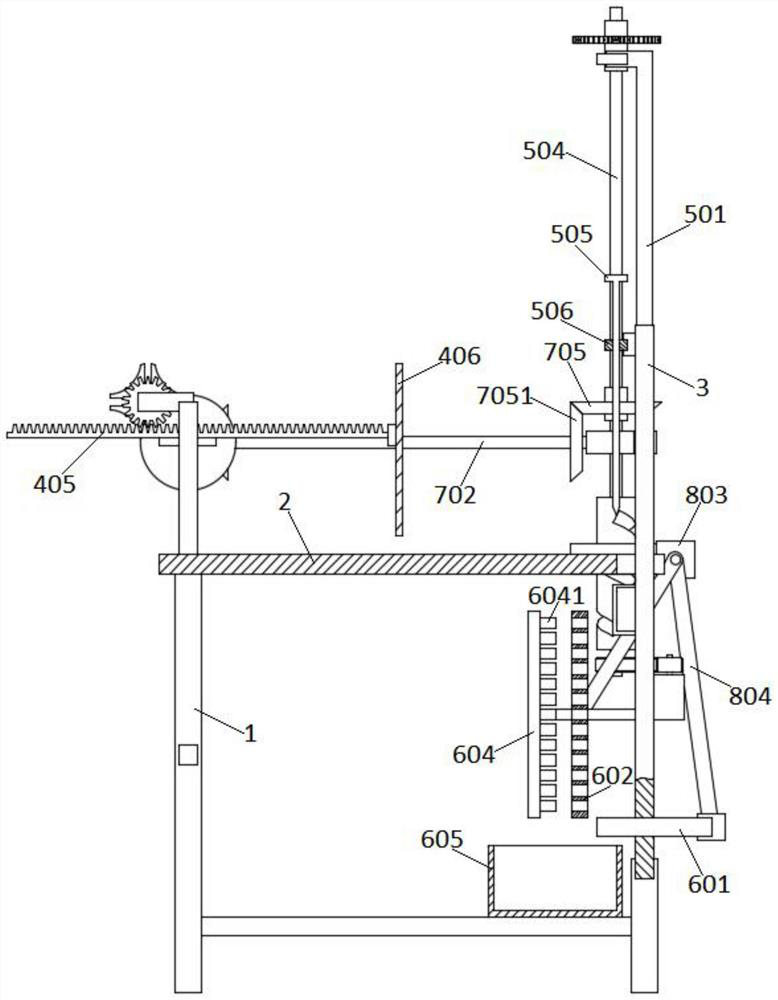

[0033] see Figure 1-2 As shown, the present invention is a kind of animal fat crushing and granulating device based on linkage, comprising a frame 1; the frame 1 adopts a conventional frame structure in the art; the upper part of the frame 1 is horizontally fixed with an operating panel 2; the operating panel 2 One edge of one edge is provided with feed opening 201; The width of feed opening 201 is the thickness of single animal fat sheet, can select 1-2cm; The length of feed opening is 1-2cm than the length of single animal fat sheet; One side of the load plate 3 is vertically fixed, and the load plate 3 is placed in the discharge port 201 on one side close to the operation plate 2; the lower end of the load plate 3 is fixed on the frame 1; There is a pushing assembly 4 corresponding to the feeding port 201; a cutting assembly 5 is installed above the feeding port 201; a granulation assembly 6 is installed below the feeding port 201; the pushing assembly 4 and the cutting as...

specific Embodiment 2

[0036] This embodiment is further optimized on the basis of specific embodiment one, specifically as follows:

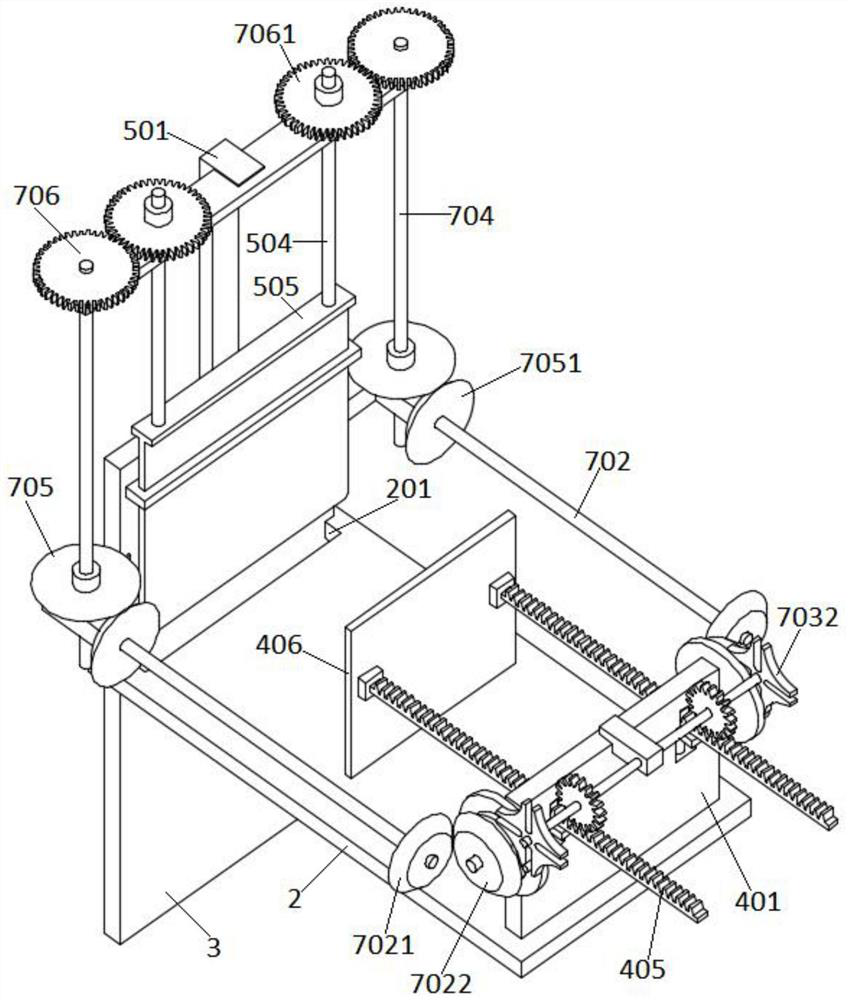

[0037] Such as Figure 3-6 As shown, the pusher assembly 4 includes a support plate 401 vertically fixed on the upper surface of the operating panel 2; the support plate 401 is arranged in parallel with the bearing plate 3; the upper edge of the support plate 401 is fixed with a first mounting block 402; the first mounting block 402 rotates away from one end of the bearing plate 3 and is interspersed with a vertically arranged drive shaft 403; the length direction of the drive shaft 403 is arranged parallel to the length direction of the feeding port 201; a pair of first gears 404 are fixed side by side on the drive shaft 403; the first gear 404 There is a transmission rack 405 engaged on the top; the transmission rack 405 slides and penetrates on the bearing plate 3; the ends of the two transmission racks 405 close to the bearing plate 3 are connected by a pusher pl...

specific Embodiment 3

[0041] This embodiment is further optimized on the basis of specific embodiment two, specifically as follows:

[0042] Such as Figure 2-4 and Figure 7-9 As shown, the first transmission assembly 7 includes a pair of second mounting blocks 701 respectively fixed on opposite sides of the bearing plate 3; A first transmission shaft 702 is rotatably connected; one end of the first transmission shaft 702 is fixed with a first bevel gear 7021; the first bevel gear 7021 is meshed with a second bevel gear 7022; the second bevel gear 7022 is fixed on a connecting shaft 703 The connecting shaft 703 is rotatably connected to the side of the support plate 401; the connecting shaft 703 is arranged in parallel with the driving shaft 403; a driving dial 7031 is fixed on the connecting shaft 703; a matching sheave 7032 is arranged on one side of the driving dial 7031 The sheave 7032 is fixed on the drive shaft 403; the second mounting block 701 is rotated and interspersed with a second tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com