Method for determining current-carrying capacity of direct-current cable with metal sheath serving as return line

A technology of DC cables and metal sheaths, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of unsuitable DC cable ampacity, etc., and achieve the effect of ensuring long-term stable operation and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

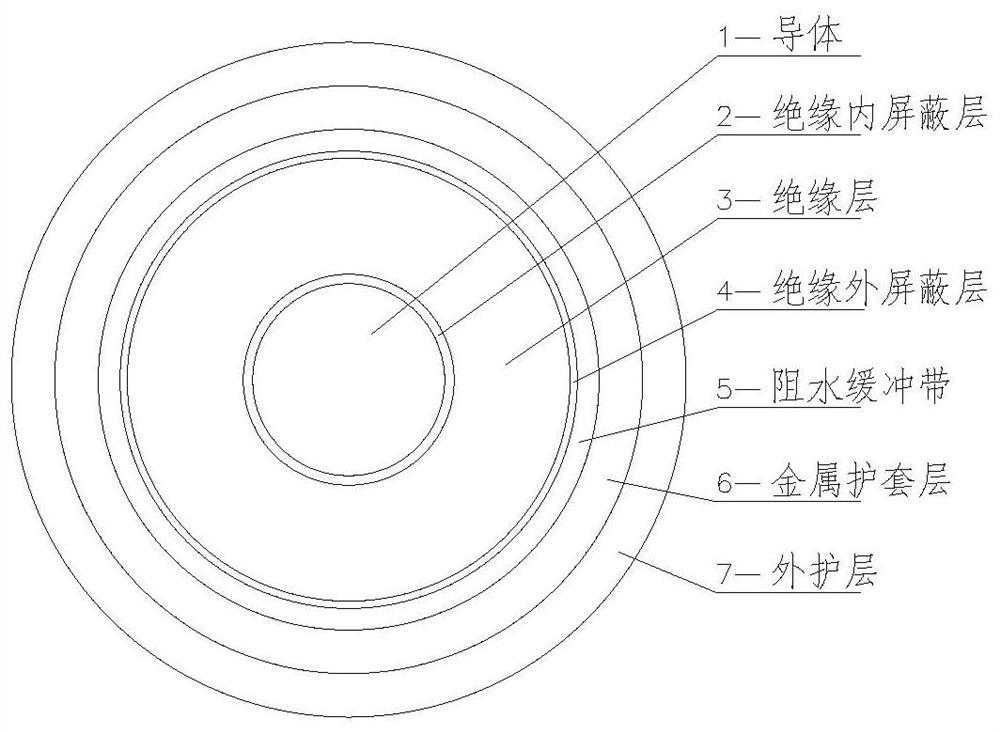

[0037] In this embodiment, a metal sheath doubles as a DC cable for the return line, such as figure 1 As shown, it includes: a conductor 1, an insulating inner shielding layer 2, an insulating layer 3, an insulating outer shielding layer 4, a water-blocking buffer strip 5, a metal sheath layer 6, and an outer sheathing layer 7.

[0038]In this embodiment, the conductor 1 is made of electrical copper, aluminum or alloy materials; the insulating inner shielding layer 2 is made of semi-conductive materials; the insulating layer 3 is made of cross-linked polyethylene or other insulating materials; The shielding layer 4 is made of semi-conductive materials; the metal sheath layer 6 is made of metal sheaths such as copper, aluminum or lead; the outer sheath layer 7 is made of high-density polyethylene. In this embodiment, the ampacity of the DC cable is controlled by the maximum long-term allowable temperature of the conductor 1 and the maximum allowable temperature difference betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com