Photovoltaic junction box

A technology of volt junction box and terminal, applied in the field of solar photovoltaic modules, can solve the problems of large size of the junction box, decreased waterproof performance, troublesome production process, etc., and achieve the effects of large contact area, short production time, and simple and convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

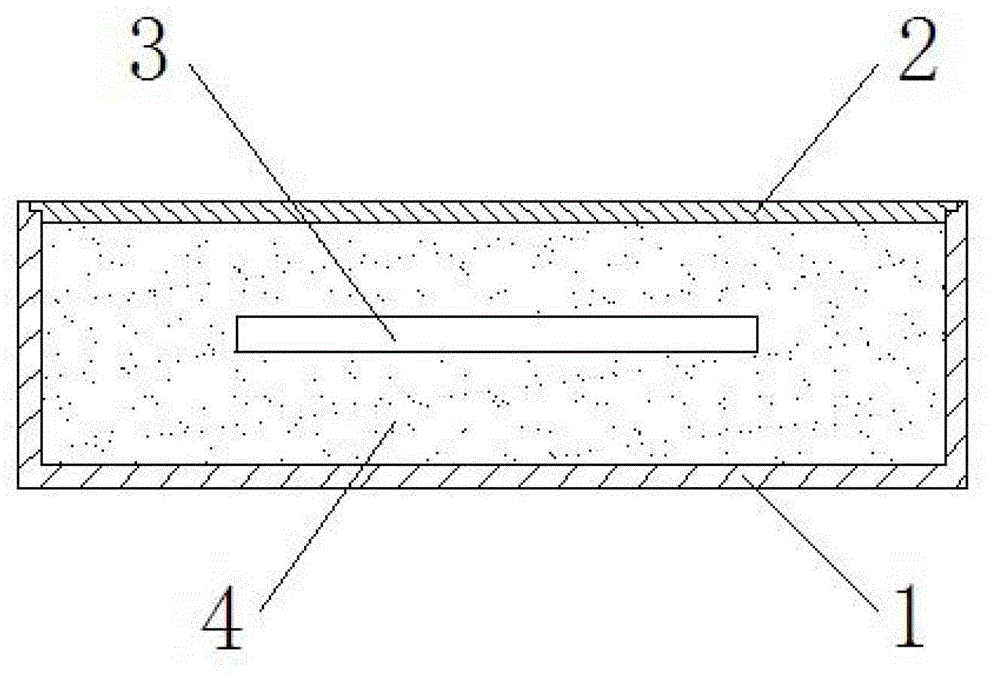

[0020] Such as figure 1 and figure 2 As shown, a photovoltaic junction box of the present invention includes a box body 1, a box cover 2, and an electrical component 3. The box body 1 and the box cover 2 form a cavity, and the electrical component 3 is arranged in the cavity; It is filled with insulating and heat-conducting filler, and the filler is quartz sand filler 4 . Quartz sand has high thermal conductivity and insulation properties, and has a large contact area with the arc, which is convenient for absorbing arc energy, so the arc can be cooled rapidly.

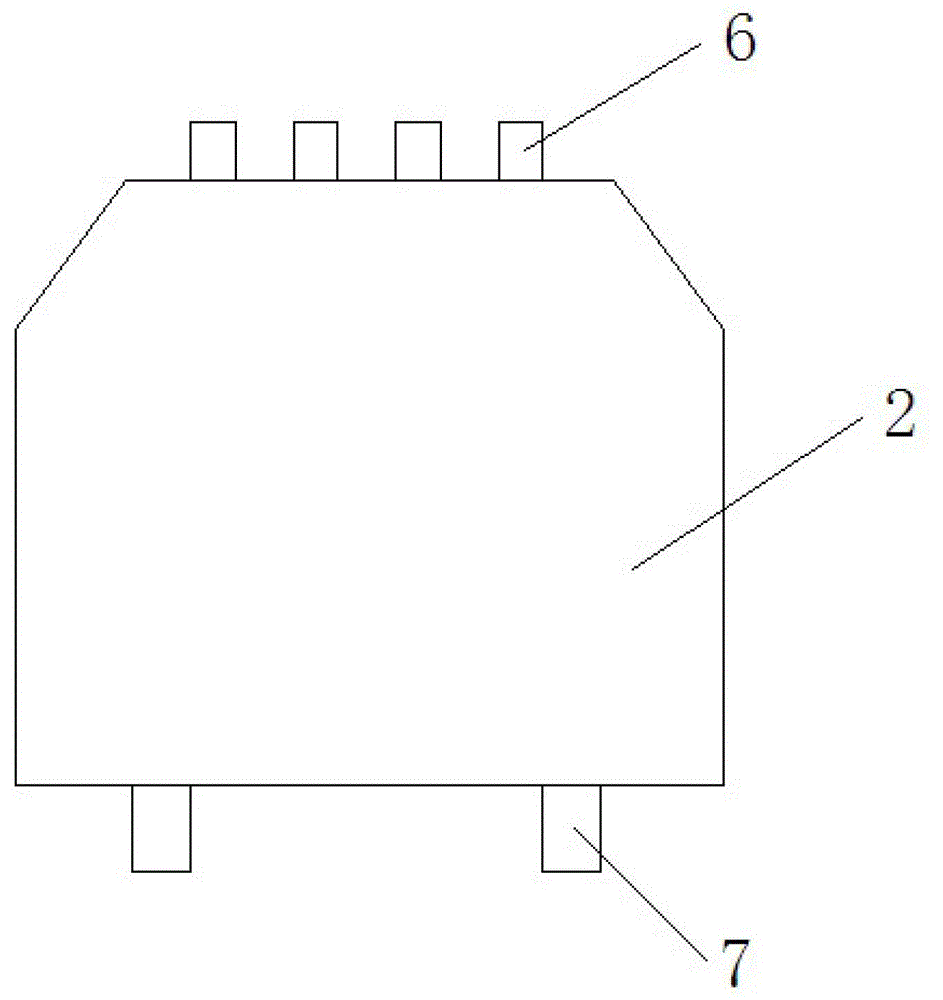

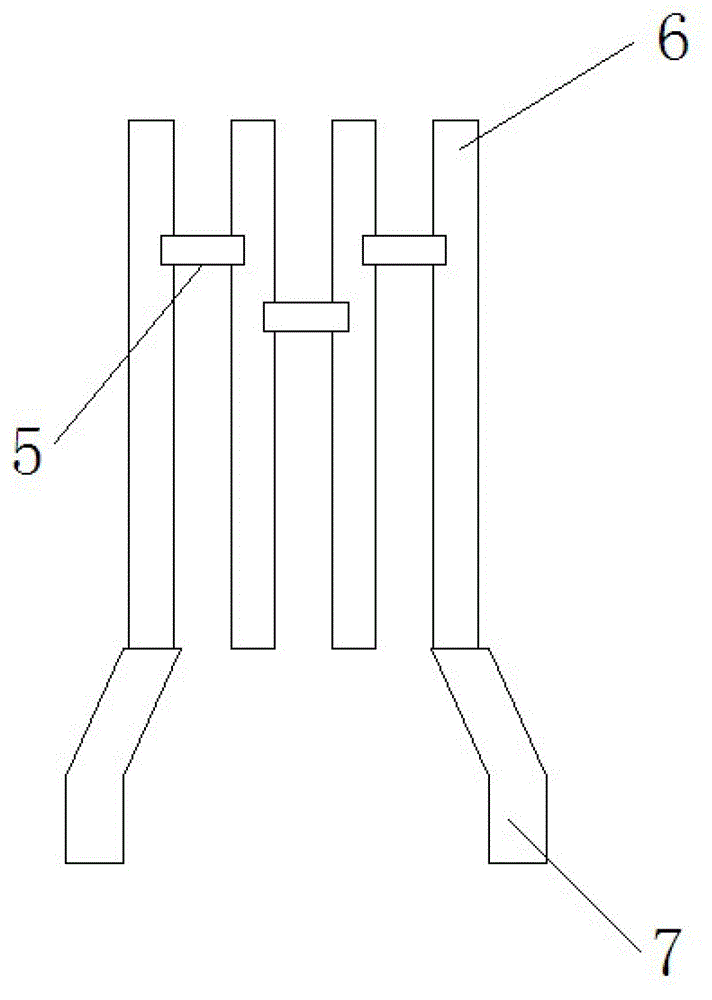

[0021] Such as image 3 As shown, the electrical assembly 3 includes a diode 5 , a conductive connecting piece 6 and a cable connecting piece 7 , the diode 5 is electrically connected between the conductive connecting pieces 6 , and the cable connecting piece 7 is electrically connected to the conductive connecting piece 6 . The terminal of the conductive connection piece 6 and the terminal of the cable connection ...

Embodiment 2

[0024] The rest are the same as in Embodiment 1, the difference is that one diode 5 is provided, two conductive connecting pieces 6 are provided, and the two conductive connecting pieces 6 are arranged at intervals to form a gap, and the diode 5 is arranged in the gap, and is connected to the two conductive connecting pieces 6. The conductive connecting piece 6 at the end is electrically connected. The cable connecting pieces 7 are electrically connected to the conductive connecting pieces at the left and right ends respectively.

[0025] The beneficial effect of adopting the technical solution is: by using quartz sand as the filling material, the requirements of insulation, heat conduction, sealing and resistance of the junction box are met, and at the same time, the production process is simple and convenient, and the production time is short, thereby effectively improving the production efficiency of the product. Quartz sand has high thermal conductivity and insulation prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com