Watermelon enzyme fermentation tank capable of enabling materials to uniformly and fully absorb bacterial powder

A technology of full absorption and enzyme fermentation, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biological material sampling method, etc., can solve the problem of easily polluted culture environment and uneven distribution of bacterial powder , Insufficient absorption of bacteria powder by watermelon enzyme and other problems, to achieve the effect of facilitating fermentation, reducing the probability of entering the interior of the fermentation tank, and avoiding uneven spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

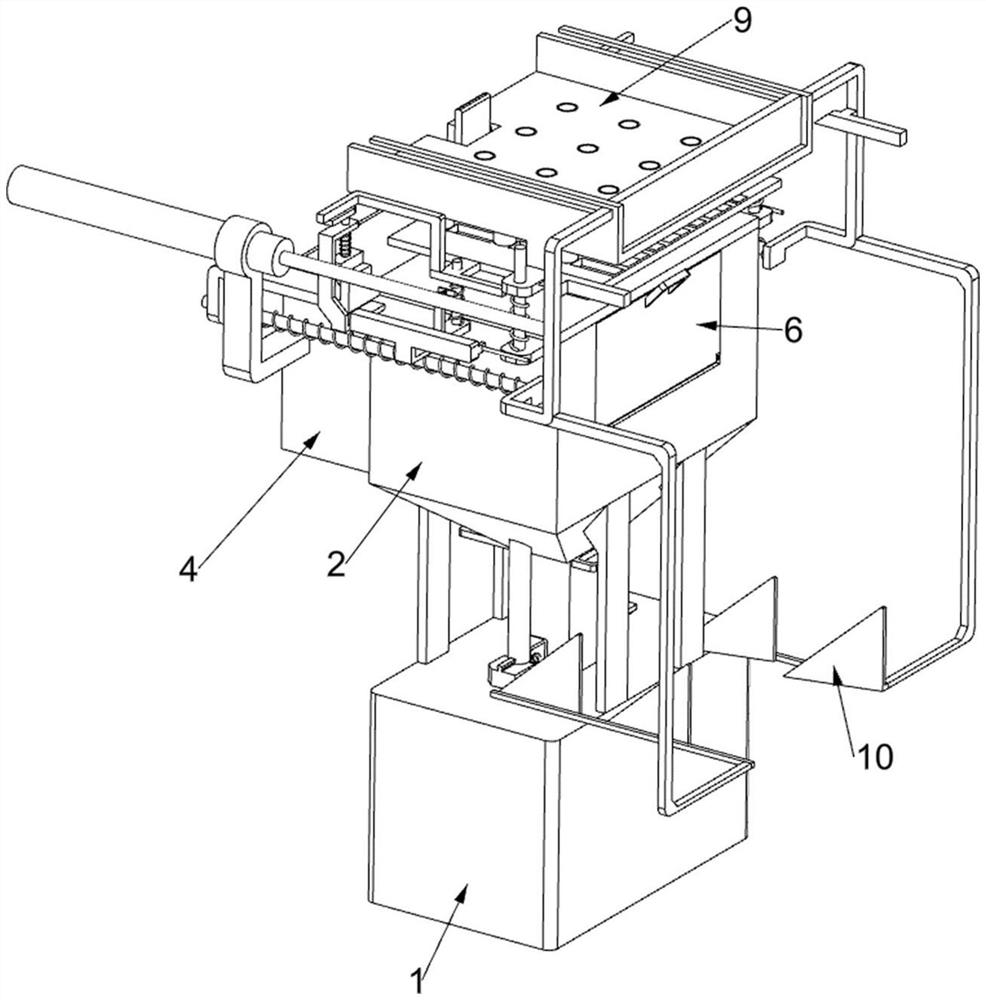

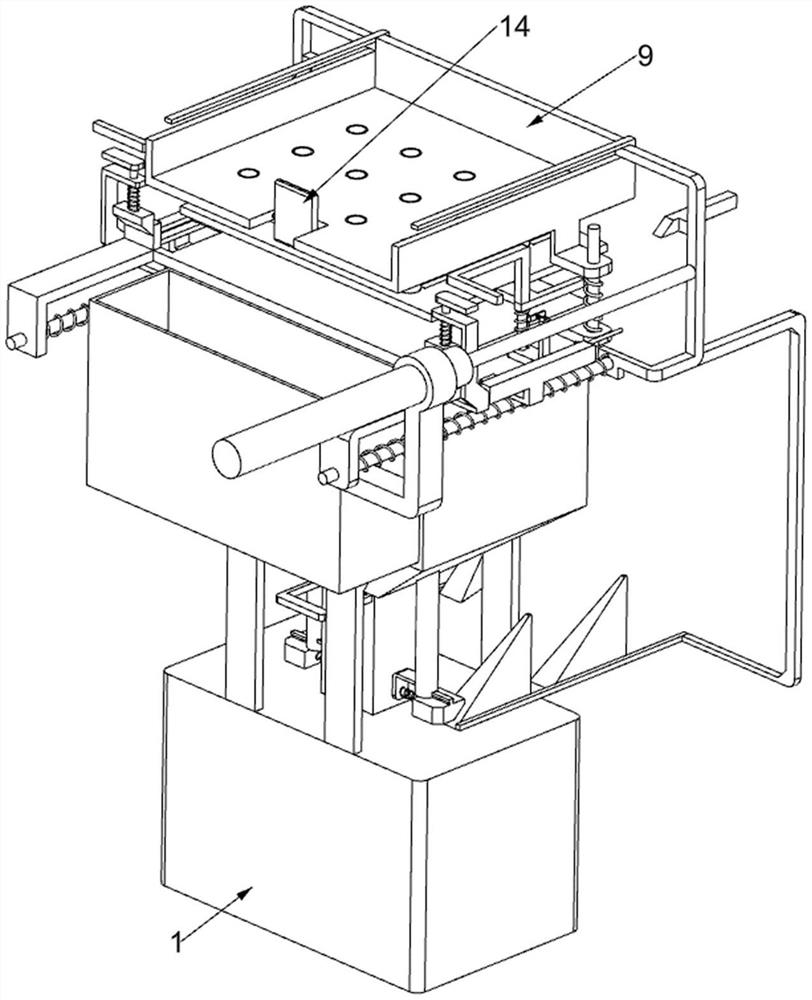

[0049] A kind of watermelon enzyme fermenter that can make the material uniform and fully absorb the bacteria powder, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it includes a first collection frame 1, a fermentation tank 2, an agitation frame 3, a second collection frame 4, a first opening and closing plate 5, a rotary door 6, a sealing frame 7, a first torsion spring 8, a pushing mechanism 9 and agitation Mechanism 10, the outer top of the first collecting frame 1 is connected with a fermenter 2, and the fermenter 2 is symmetrically slidingly connected with an agitation frame 3 for fully stirring and mixing the fermentation raw materials and bacteria powder inside the fermenter 2, and the outer wall of the fermenter 2 One side is connected with a second collection frame 4 for collecting excess bacteria powder, the fermenter 2 is slidably connected with a first opening and closing plate 5, ...

Embodiment 2

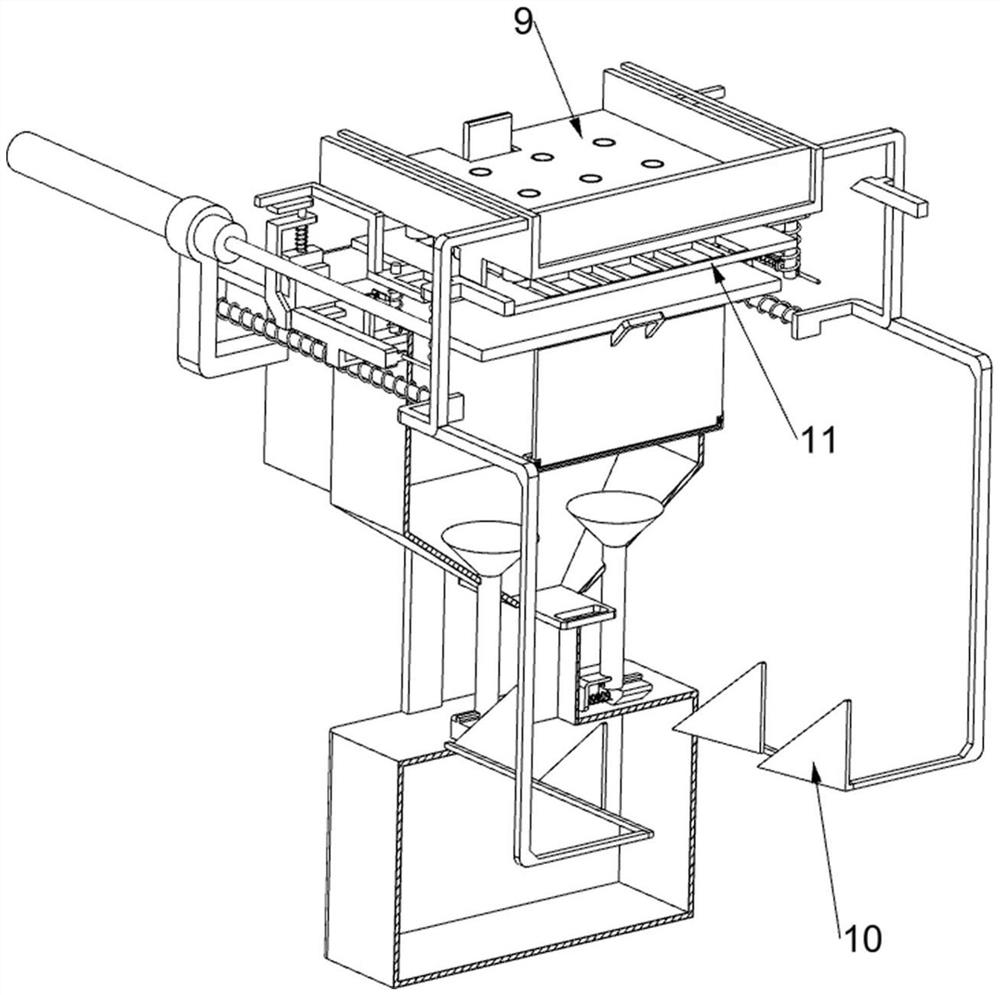

[0054] On the basis of Example 1, such as Figure 10 , Figure 11 , Figure 12 and Figure 13 Shown, also include uniform feeding mechanism 11, the uniform feeding mechanism 11 that is used to add bacteria powder evenly is located on fermenter 2, and uniform feeding mechanism 11 includes the 3rd fixed frame 111, sliding plate 112, the 3rd fixing frame 111, the 1st Three return springs 113, the second fixed rod 114, the first sliding frame 115, the fourth return spring 116, the fourth fixed frame 117, the second opening and closing plate 118 and the sliding pipe 119, the fermentor 2 outer wall both sides are fixedly connected with the third The fixed frame 111, the third fixed frame 111 is slidably connected with a sliding plate 112, the third return spring 113 is connected between the sliding plate 112 and the third fixed frame 111, and the top of the sliding plate 112 is connected with a second fixed rod 114. A sliding frame 115 is slidably connected to the second fixed ro...

Embodiment 3

[0057] On the basis of Example 2, such as Figure 14 As shown, it also includes a dosing mechanism 12, which is used to increase or decrease the amount of bacterial powder that needs to be added according to production needs. and the fifth return spring 123, the top of the sliding plate 112 is fixedly connected with a fixed plate 121, and the fixed plate 121 is slidably connected with a first wedge-shaped block 122 for temporarily clamping the first sliding frame 115, and the top of the first wedge-shaped block 122 is The slope is shaped like a fifth return spring 123 connected between the first wedge block 122 and the fixing plate 121 .

[0058] When it is necessary to add more bacteria powder to the inside of the fermenter 2, manually press the first sliding frame 115 and its upper device to move downward, and the fourth back-moving spring 116 will be compressed thereupon, through the first wedge-shaped block 122 and the fifth With the cooperation of the back-moving spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com