Multi-layer composite bionic polymer valve leaflet and manufacturing method thereof

A multi-layer composite and polymer technology, applied in the field of medical devices, can solve the problem of not being able to simulate the stress of natural valves well, and achieve the effect of reducing the overall valve size, improving the opening and closing performance, and simple manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

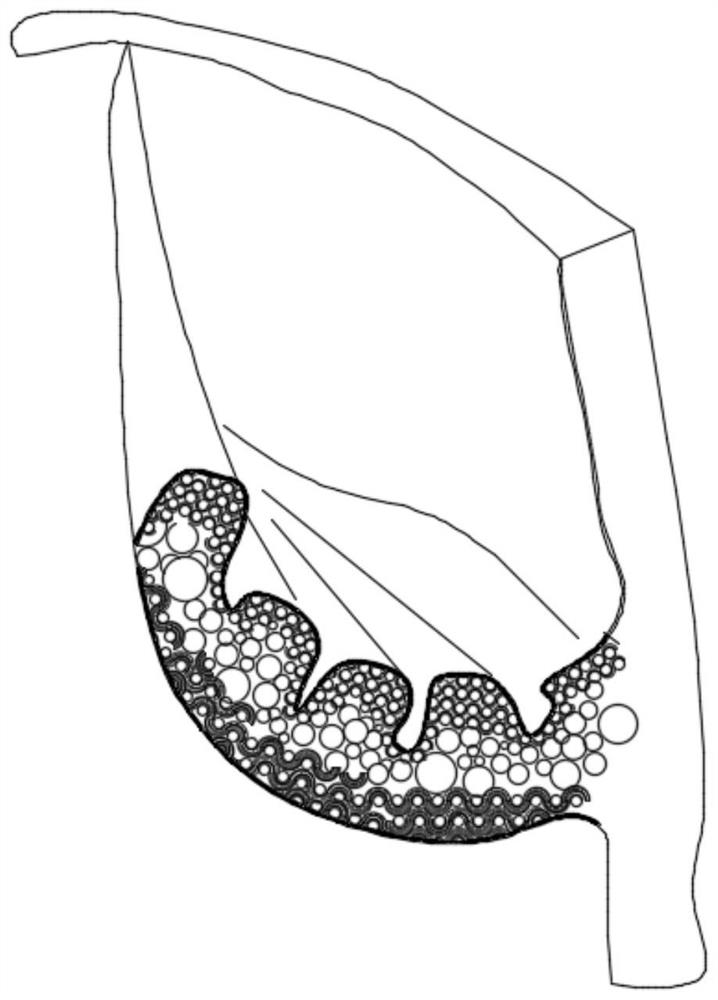

[0057] Such as figure 1 As shown, the structure of the natural valve can be roughly divided into three layers. There are two layers of fibrous layers above and below, which are used to withstand the stress of blood flow impact, and the middle layer is a sponge layer, which can provide buffering effect.

[0058] In the first example, a multi-layer composite bionic polymer leaflet has an overall thickness of 100 microns: the first fiber layer 1: high-strength ultra-high molecular weight polyethylene (UHMWPE) fibers in the circumferential direction, polyurethane elastic fibers in the radial direction Woven into a cloth with a thickness of 30 microns; the porous polymer sponge layer 2 is porous polyurethane sponge with an average pore size of 300 microns and a thickness of 40 microns; the second fiber layer 3 is radial ultra-high molecular weight polyethylene (UHMWPE), and the circumferential It is polyurethane elastic fiber with a thickness of 30 microns.

[0059] The manufactur...

Embodiment 2

[0069] In the second embodiment, a multi-layer composite bionic polymer leaflet has an overall thickness of 140 microns: the first fiber layer: high-strength ultra-high molecular weight polyethylene (UHMWPE) fibers in the circumferential direction, polyurethane elastic fibers in the radial direction Woven into cloth with a thickness of 40 microns; the sponge layer is porous polyurethane sponge with an average pore size of 300 microns and a thickness of 60 microns; the second fiber layer 2 is ultra-high molecular weight polyethylene (UHMWPE) in the radial direction, and polyurethane elastic fibers in the circumferential direction , with a thickness of 40 microns.

[0070] The manufacturing method and testing process of the bionic polymer leaflet are as follows:

[0071] The first step: arrange the ultra-high molecular weight polyethylene fiber monofilaments (with a tensile strength of 5Gpa and a diameter of 20 microns) in the circumferential direction, and then arrange the poly...

Embodiment 3

[0079] In the third embodiment, a multi-layer composite bionic polymer leaflet has an overall thickness of 180 microns: the first polymer fiber layer: high-strength ultra-high molecular weight polyethylene (UHMWPE) fibers in the circumferential direction, polyurethane elastic in the radial direction The fiber is woven into a cloth with a thickness of 60 microns; the sponge layer is porous ePTFE sponge with an average pore size of 300 microns and a thickness of 80 microns; the second fiber layer 2 is radial ultra-high molecular weight polyethylene (UHMWPE), and the circumferential direction is polyurethane elastic Fiber, 40 microns thick.

[0080] The manufacturing method and testing process of the bionic polymer leaflet are as follows:

[0081] The first step: arrange the ultra-high molecular weight polyethylene fiber monofilaments (with a tensile strength of 5Gpa and a diameter of 20 microns) in the circumferential direction, and then arrange the polyurethane elastic fiber mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com