Bent cap production line system

A production line and beam covering technology, which is applied in the direction of manufacturing tools, grinding slides, auxiliary molding equipment, etc., can solve the problems of low concrete pouring efficiency, unsuitable for factory operation, waste of manpower and time, etc., and achieves easy maintenance and cleaning. The effect of improving construction safety and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

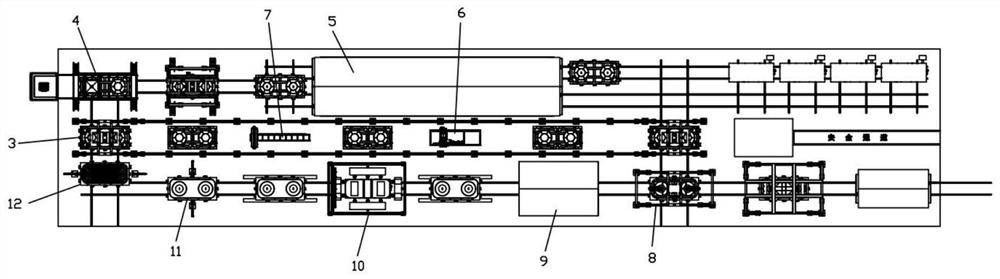

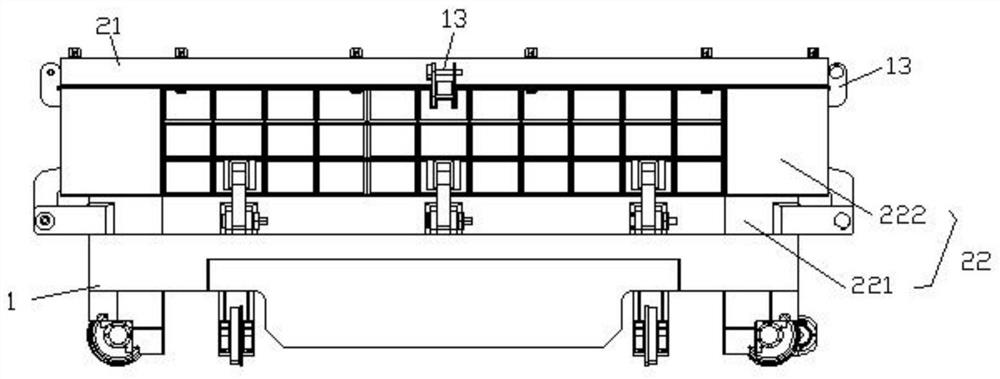

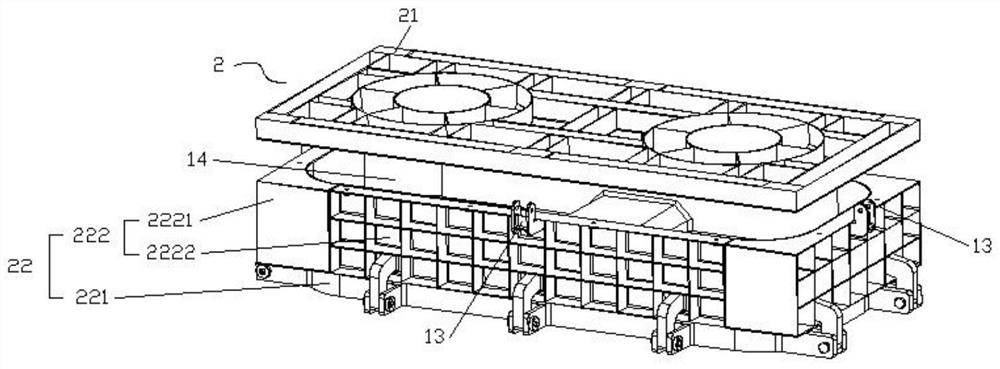

[0056] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0057] Such as Figure 1-Figure 4 As shown, the cover beam production line system of the present application includes the cover beam split mold 2 placed on the AGV trolley 1 and the upper formwork opening / closing station 3, concrete pouring and vibrating station 4, Maintenance station 5, upper template grinding station 6, upper template spraying station 7, lower template mold opening station 8, lower template grinding station 9, lower template spraying station 10, long template mold clamping station 11 and short template Template clamping station 12;

[0058] The cover beam split mold 2 includes an upper template 21 and a lower template 22, and the lower template 22 includes a bottom template 221 and a side template 222;

[0059] The bottom template 221 is placed on the AGV trolley 1, and the concave-convex molding structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com