Preparation method of nano-antibacterial mixed solution and nano-antibacterial filter material

A mixed liquid and nanotechnology, applied in the direction of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems of poor dispersion, achieve high-efficiency antibacterial performance, strong polarization, and easy adsorption of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

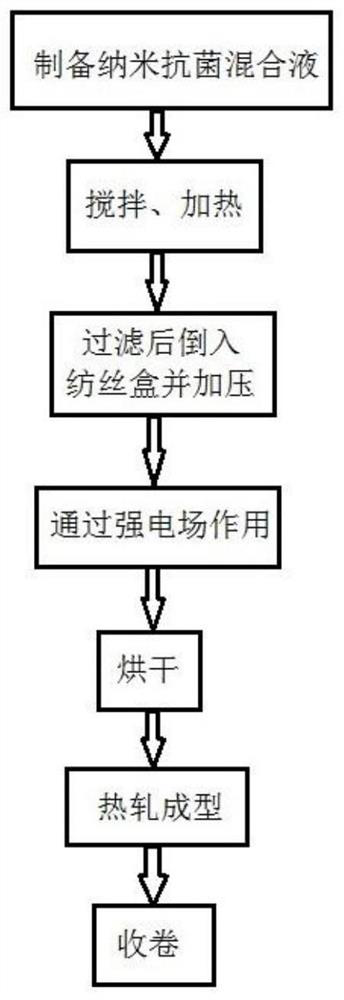

Image

Examples

Embodiment 1

[0038] A nano-antibacterial mixed solution, each component in the nano-antibacterial mixed solution and their weight percentages are: biguanide accounts for 0.5%, gelatin accounts for 12%, and formic acid accounts for 87.5%.

[0039] Then pour the formic acid, biguanide, and gelatin in the above proportions into the reaction kettle in order to stir, heat to 60±5°C and continue stirring for about 1 hour, turn off the heating system, and continue stirring for 12 hours; after the stirring is completed, filter the spinning solution Pour it into the spinning box, connect the liquid supply pipe in series and connect it to the spinning head; open the air valve to supply air to the spinning box, and the gas compressed spinning solution flows out through the spinning head; turn on the high-voltage power supply to make the voltage reach 50-60KV, and flow out The spinning solution generates nanofibers under a strong electric field and is immediately absorbed into the non-woven fabric; the...

Embodiment 2

[0041] A nano antibacterial mixed solution, each component in the nano antibacterial mixed solution and their weight percentages are: PA6 accounts for 10.5%, quaternary phosphonium salt accounts for 0.5%, formic acid accounts for 44%, and acetic acid accounts for 45%.

[0042] Then pour the formic acid, acetic acid, PA6, and quaternary phosphonium salts in the above proportions into the reactor in order to stir, heat to 60±5°C and continue stirring for about 1 hour, turn off the heating system, and continue stirring for 12 hours; after the stirring is completed, the spinning After the silk liquid is filtered, it is poured into the spinning box, and the liquid supply pipe is connected in series and connected to the spinning head; the air valve is opened to supply air to the spinning box, and the gas-compressed spinning solution flows out through the spinning head; the high-voltage power supply is turned on to make the voltage reach 50 -60KV, the outflowing spinning solution gene...

Embodiment 3

[0044] A nano antibacterial mixed solution, each component in the nano antibacterial mixed solution and its weight percentage are: PA6 accounts for 10.5%, biguanide accounts for 0.5%, formic acid accounts for 44%, and acetic acid accounts for 45%.

[0045]Then pour the formic acid, acetic acid, PA6, and biguanide in the above ratio into the reaction kettle in order to stir, heat to 60±5°C and continue stirring for about 1 hour, turn off the heating system, and continue stirring for 12 hours; after the stirring is completed, the spinning solution After filtering, pour it into the spinning box, connect the liquid supply pipe in series and connect it to the spinning head; open the air valve to supply air to the spinning box, and the gas compressed spinning solution flows out through the spinning head; turn on the high voltage power supply to make the voltage reach 50-60KV , the outflowing spinning solution generates nanofibers under a strong electric field and is immediately absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com