Laser weldable hook-and-loop fastener

A technology of laser welding and fixing parts, which is applied in the direction of fasteners, vehicle parts, clothing, etc., and can solve the problems of not being able to think of convex forming surface fixing parts, no finger surface fixing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0144] Hereinafter, the present invention will be specifically described by way of examples and comparative examples. In Examples and Comparative Examples, the laser welding and the presence or absence of lodging of the convex engaging member were evaluated as follows.

[0145] Laser weldability

[0146] The convex molding surface fixing material laser-welded on the back surface of the automotive roof material is peeled off, and the peeled surface is observed to evaluate the welding state.

[0147] Presence or absence of lodging of convex engaging parts

[0148] Use a magnifying glass to observe the state of the convex engaging part laser-welded on the surface of the convex forming surface fixing member on the back surface of the automotive roof material, and observe the degree of lodging of the convex engaging part.

[0149] And, the initial adhesive force at room temperature (20° C.) and 110° C. of the male surface fixing member laser welded to the back surface of the auto...

manufacture example 1

[0150]Manufacturing Example 1: Manufacturing of Convex Forming Surface Fixing Tool (A-1)

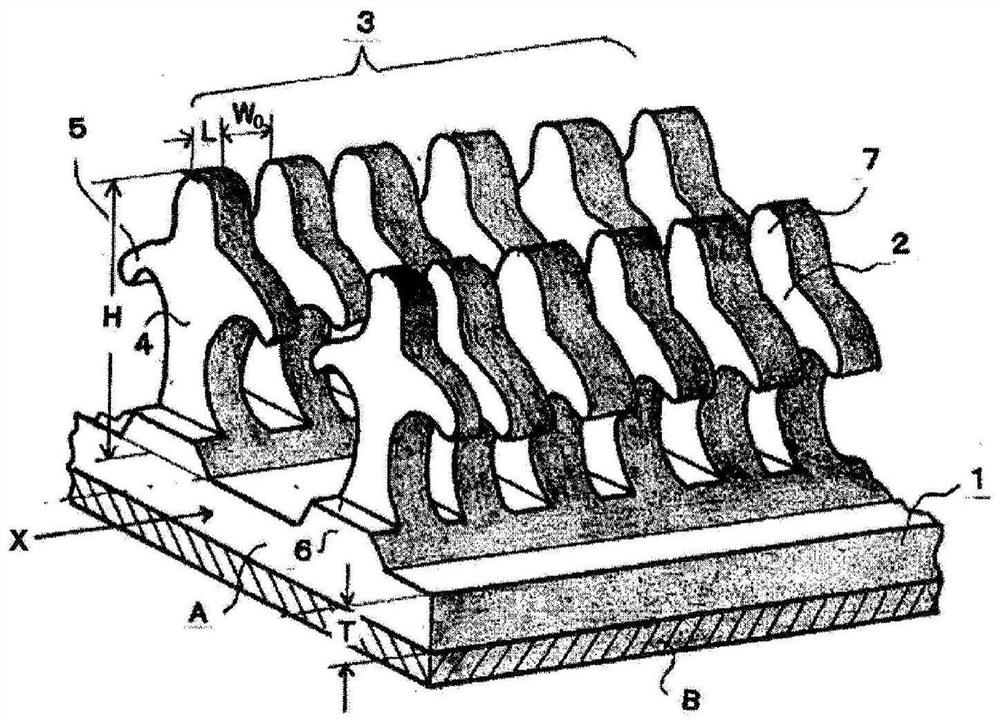

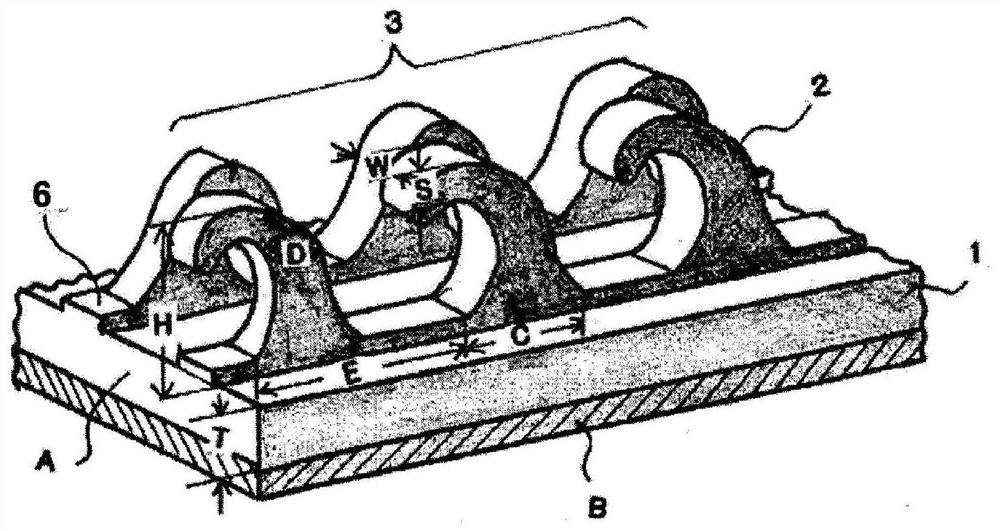

[0151] Except that the male snap-fit part is a two-stage arrow-shaped snap-in part, use and follow figure 1 The nozzle with the same cross-sectional shape viewed in the arrow (X) direction extrudes a polyester elastomer ("Hai Cui" ((registered trademark) 6377) manufactured by Toray DuPont Co., Ltd.), cools it, and shapes it into a multi- A strip of tape for a male snap-fit part.

[0152] Such as figure 1 As shown, on the upper surface of the substrate (1) made of polyester elastomer, the rows of rows for the convex engaging parts (2) made of the same polyester elastomer and having upper and lower two-stage protrusions stand up.

[0153] The width of the adhesive tape is 40 mm, and the number of the strips is six per 1 cm of the adhesive tape width.

[0154] Slits were inserted into the row from the front end of the row to 4 / 5 of the height of the row (1 / 5 from the bottom) at inter...

manufacture example 2

[0157] Manufacturing Example 2: Manufacturing of Convex Forming Surface Fixing Tool (A-2)

[0158] In the manufacture example 1, except having changed the polyester elastomer into polypropylene, it carried out similarly to manufacture example 1, and manufactured the convex molding surface fastener (A-2). The infrared transmittance and absorptivity at a wavelength of 980 nm of this convex molding surface fixture (A-2) were 46.2% and 30.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com