Solid oxide fuel cell electrode material and preparation method thereof

A fuel cell electrode, solid oxide technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of high interface polarization resistance and low chemical catalytic activity, and achieve low interface polarization resistance and simple operation. , the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

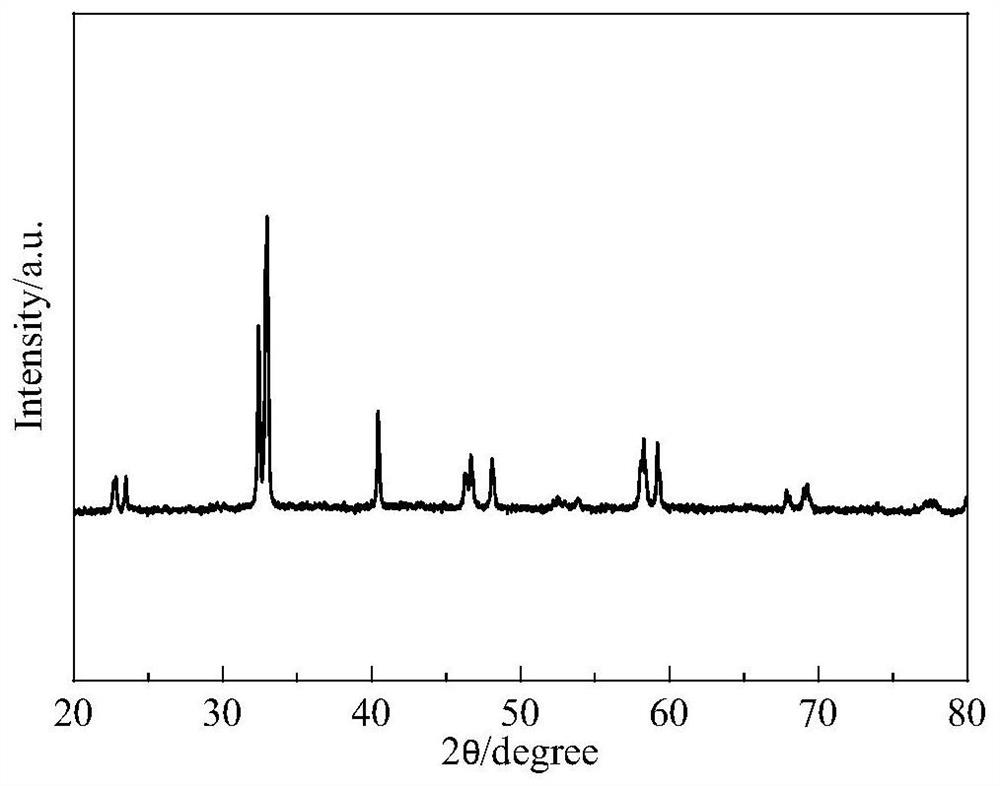

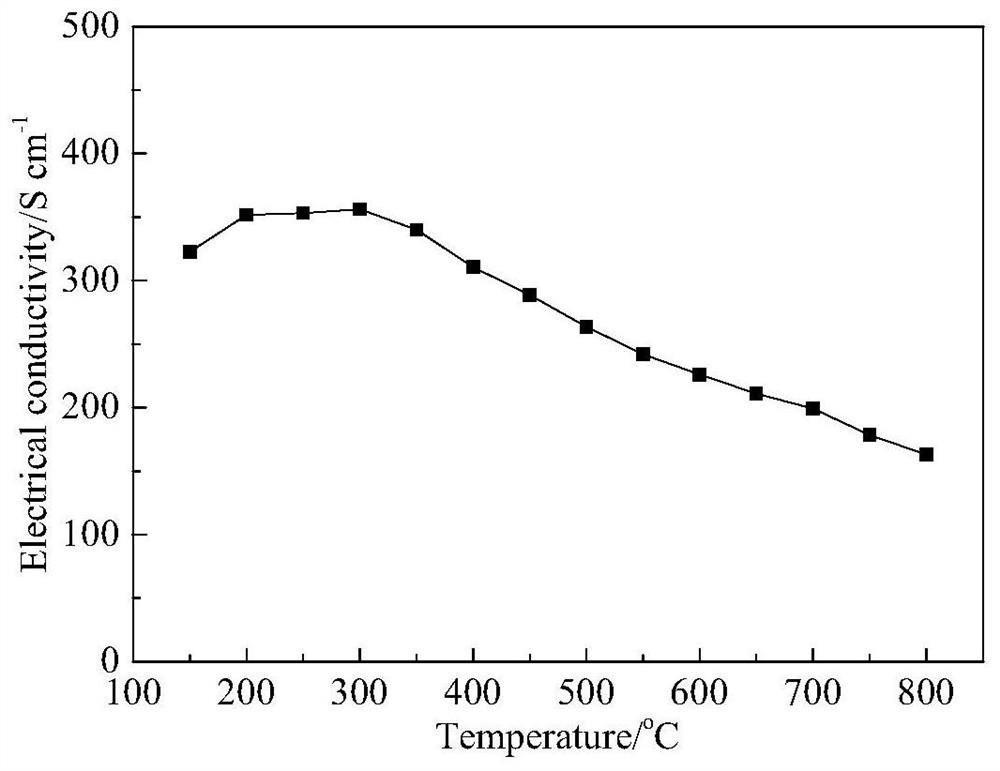

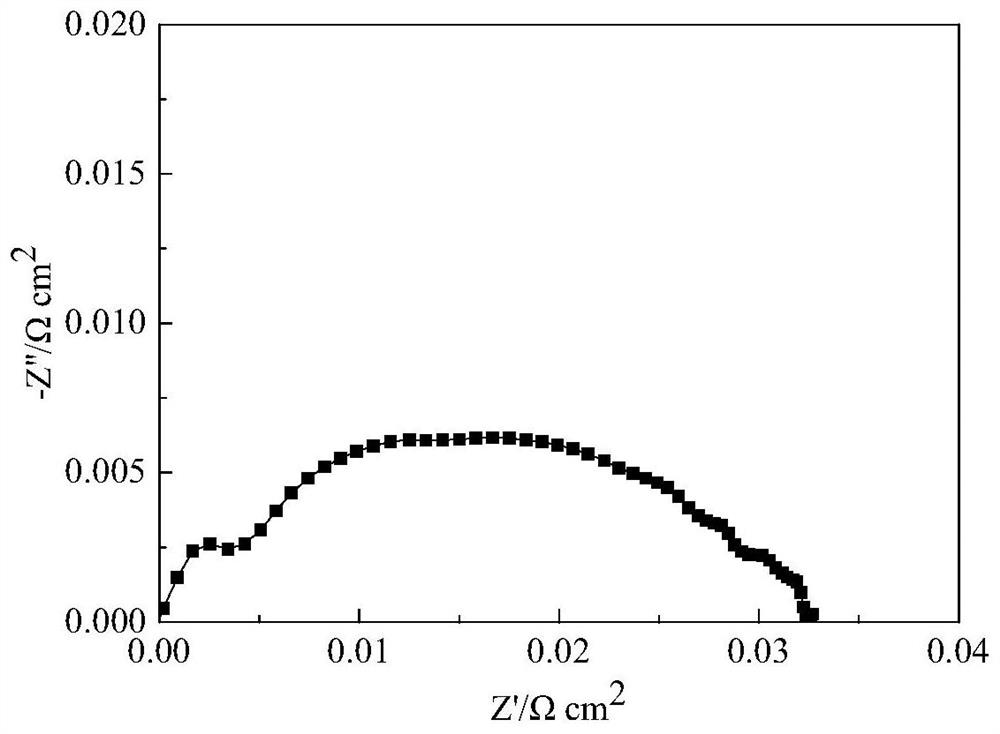

[0040] This embodiment provides a kind of medium temperature solid oxide fuel cell cathode material, chemical formula is SmBa 0.9 Ca 0.1 co 1.5 Fe 0.5 o 5+δ , δ is the content of oxygen vacancies, and the content of oxygen vacancies in the sample is measured by iodometric titration method δ=0.72.

[0041] In this example, SmBa 0.9 Ca 0.1 co 1.5 Fe 0.5 o 5+δ A method for preparing a cathode material for a medium-temperature solid oxide fuel cell, comprising the following steps:

[0042] (a) According to the stoichiometric ratio of the chemical formula, weigh Sm 2 o 3 8.72g, BaCO 3 8.88g, CaCO 3 0.5g, Co 2 o 3 6.22g and Fe 2 o 3 2.0g raw material;

[0043] (b) Fully mix all the above-mentioned weighed powders with deionized water and balls, the mass ratio of material: balls: water is 1:2:3, and put it on a planetary ball mill for ball milling. The speed of the ball mill is 300r / min. The ball milling time is 8 hours. After ball milling, pour the material into a ...

Embodiment 2

[0052] This embodiment provides a kind of medium temperature solid oxide fuel cell cathode material, chemical formula is SmBa 0.8 Ca 0.2 co 1.25 Fe 0.75 o 5+δ , δ is the content of oxygen vacancies, and the content of oxygen vacancies in the sample is measured by iodometric titration method δ=0.76.

[0053] In this example, SmBa 0.8 Ca 0.2 co 1.25 Fe 0.75 o 5+δ A method for preparing a cathode material for a medium-temperature solid oxide fuel cell, comprising the following steps:

[0054] (a) According to the stoichiometric ratio of the chemical formula, weigh Sm 2 o 3 8.72g, BaCO 3 7.89g, CaCO 3 1.0g, Co 2 o 3 5.18g and Fe 2 o 3 3.0g raw material;

[0055] (b) Fully mix all the above-mentioned weighed powders with deionized water and balls, the mass ratio of material: balls: water is 1:2:3, and put it on a planetary ball mill for ball milling. The speed of the ball mill is 300r / min. The ball milling time is 16 hours. After ball milling, pour the material in...

Embodiment 3

[0064] This embodiment provides a kind of medium temperature solid oxide fuel cell cathode material, chemical formula is SmBa 0.75 Ca 0.25 CoFeO 5+δ , δ is the content of oxygen vacancies, and the content of oxygen vacancies in the sample is measured by iodometric titration method δ=0.88.

[0065] In this example, SmBa 0.75 Ca 0.25 CoFeO 5+δ A method for preparing a cathode material for a medium-temperature solid oxide fuel cell, comprising the following steps:

[0066] (a) According to the stoichiometric ratio of the chemical formula, weigh Sm 2 o 3 8.72g, BaCO 3 7.4g, CaCO 3 1.25g, Co 2 o 3 4.15g and Fe 2 o 3 4.0g raw material;

[0067] (b) Fully mix all the above-mentioned weighed powders with deionized water and balls, the mass ratio of material: balls: water is 1:2:3, and put it on a planetary ball mill for ball milling. The speed of the ball mill is 300r / min. The ball milling time is 12 hours. After ball milling, pour the material into a beaker and put it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com