Battery pole piece and preparation method and application thereof

A battery pole piece and pole piece technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrode layer expansion effect, multi-layer coating difficulty, affecting battery performance, etc., to reduce expansion effect, improving battery performance and service life, and effectively exerting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

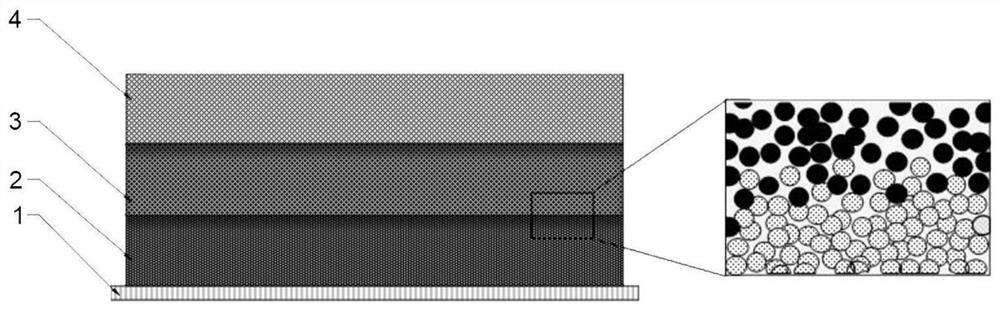

[0065] This embodiment provides a battery pole piece, such as figure 1 As shown, the battery pole piece is a positive pole piece, including a current collector 1, and one side surface of the current collector is laminated with three layers of pole piece films. Along the direction away from the surface of the current collector, the first pole piece Membrane 2, second pole piece membrane 3 and third pole piece membrane 4, wherein, the porosity of the first pole piece membrane 2 is 3.6%, the porosity of the second pole piece membrane 3 is 14.3%, the third pole piece membrane 4 has a porosity of 20.6%.

[0066] This embodiment also provides a method for preparing the above-mentioned battery pole piece, and the preparation method specifically includes the following steps:

[0067] (I) NCM523 is premixed with conductive carbon black, and then polytetrafluoroethylene is added to carry out fiberization treatment with high-speed stirring for 25s. The rotating speed of high-speed stirr...

Embodiment 2

[0071] This embodiment provides a battery pole piece, the battery pole piece is a positive pole piece, including a current collector, and one side surface of the current collector is stacked with three layers of pole piece film, along the direction away from the surface of the current collector , are respectively the first pole piece film, the second pole piece film and the third pole piece film, wherein the porosity of the first pole piece film is 5.7%, the porosity of the second pole piece film is 9.7%, and the third pole piece film The porosity of the sheet was 14.4%.

[0072] This embodiment also provides a method for preparing the above battery pole piece, the preparation method specifically includes the following steps:

[0073] (I) NCM523 is premixed with conductive carbon black, and then polytetrafluoroethylene is added to carry out fiberization treatment with high-speed stirring for 20s, and the rotating speed of high-speed stirring is 20000rpm to obtain the active ma...

Embodiment 3

[0077] This embodiment provides a battery pole piece, the battery pole piece is a negative pole piece, including a current collector, and one side surface of the current collector is stacked with three layers of pole piece films, along the direction away from the surface of the current collector , are respectively the first pole piece film, the second pole piece film and the third pole piece film, wherein the porosity of the first pole piece film is 18.2%, the porosity of the second pole piece film is 24.0%, and the third pole piece film has a porosity of 18.2%. The porosity of the sheet was 31.8%.

[0078] This embodiment also provides a method for preparing the above battery pole piece, the preparation method specifically includes the following steps:

[0079] (I) artificial graphite and conductive carbon black are premixed, then polytetrafluoroethylene is added and fiberized by high-speed stirring for 30s, and the rotating speed of high-speed stirring is 25000rpm to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com