Method for in-situ growth of nanoscale metal organic framework ZIF-8 on surfaces of polypropylene melt-blown cloth fibers

A polypropylene fiber, ZIF-8 technology, applied in the direction of fiber type, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve problems such as loss of air permeability, and achieve the effect of improving filtration performance, improving universality, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

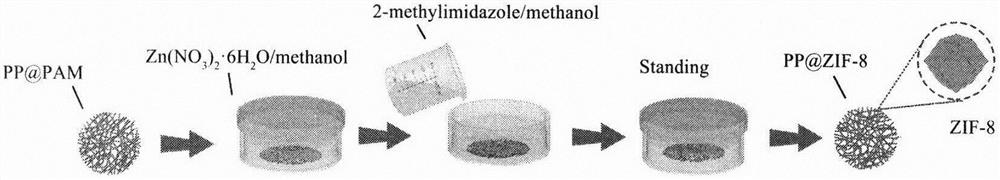

[0033] Embodiment 1-3 scheme is as follows:

[0034]

Embodiment 1

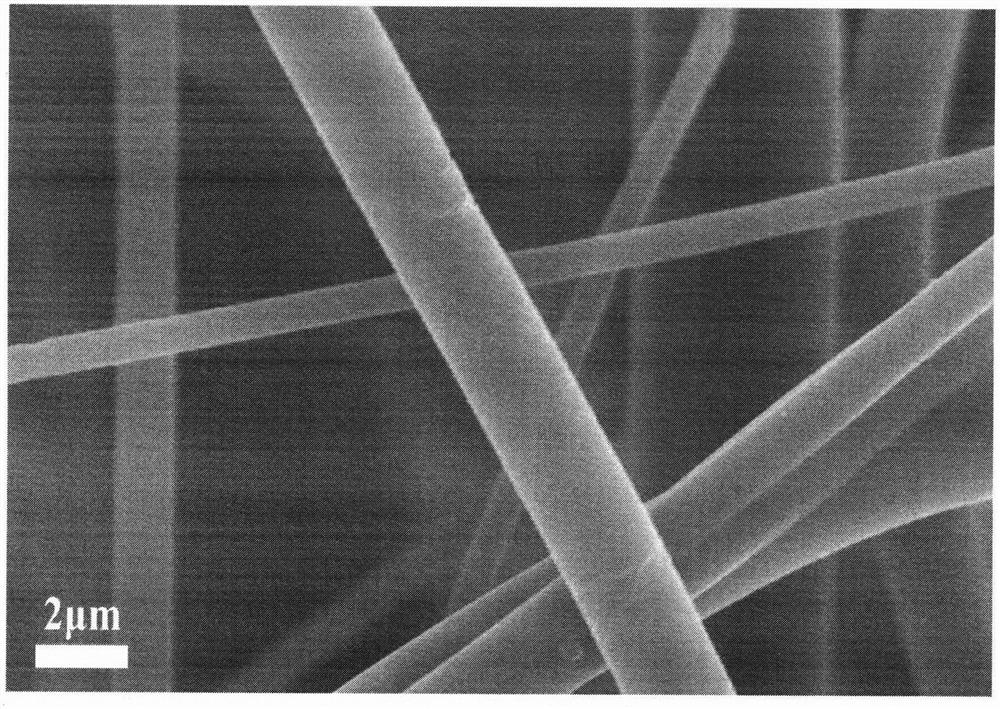

[0036] The first step is to set the gram weight to 45g / m 2 The PP fiber membrane is cut into a circle with a radius of 9cm. Then the cut PP fiber membrane was put into methanol solution (500mL), and then pretreated under 300W ultrasonic power for 30 minutes. Finally, the sample was washed three times with distilled water and dried in a conventional oven at 80°C for 12 hours to remove excess impurities and the electret effect of the fiber film.

[0037] In the second step, the dried sample is put into a solution with a polyacrylamide concentration of 0.5%, and kept for 8 hours after immersion. The samples were then taken out and dried in a conventional oven at 80°C for 12 hours.

[0038] The third step is to put the dried PP fiber membrane sample into Zn(NO 3 ) 2 ·6H 2 O / methanol solution, kept for 3 hours, called solution A.

[0039] Step 4: After mixing the dimethylimidazole / methanol solution with a molar ratio of 8:560 evenly, slowly pour it into solution A and react f...

Embodiment 2

[0042] The first step is to set the gram weight to 45g / m 2 The PP fiber membrane is cut into a circle with a radius of 9cm. Then the cut PP fiber membrane was put into methanol solution (500mL), and then pretreated under the ultrasonic power of 450W for 30 minutes. Finally, the sample was washed three times with distilled water and dried in a conventional oven at 80°C for 12 hours to remove excess impurities and the electret effect of the fiber film.

[0043] In the second step, the dried sample is put into a solution with a polyacrylamide concentration of 1%, and kept for 10 hours after immersion. The samples were then taken out and dried in a conventional oven at 80°C for 12 hours.

[0044] The third step is to put the dried PP fiber membrane sample into Zn(NO 3 ) 2 ·6H 2 O / methanol solution, kept for 3 hours, called solution B.

[0045] Step 4: After mixing the dimethylimidazole / methanol solution with a molar ratio of 7:560 evenly, slowly pour it into solution B and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com