Far-infrared antibacterial heating cotton and production and processing flow thereof

A far-infrared and far-infrared fiber technology, used in textiles and papermaking, rayon manufacturing, non-woven fabrics, etc., can solve problems such as affecting wearing comfort, and achieve excellent bulkiness, growth promotion, and good rebound effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The embodiment of the present application discloses a far-infrared antibacterial heating cotton and its production and processing flow.

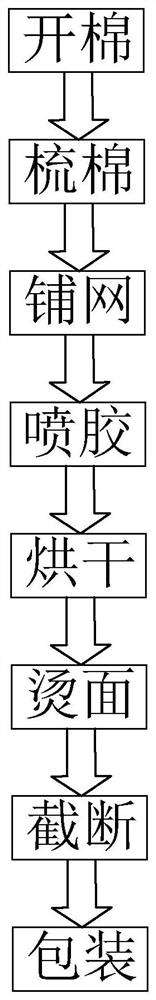

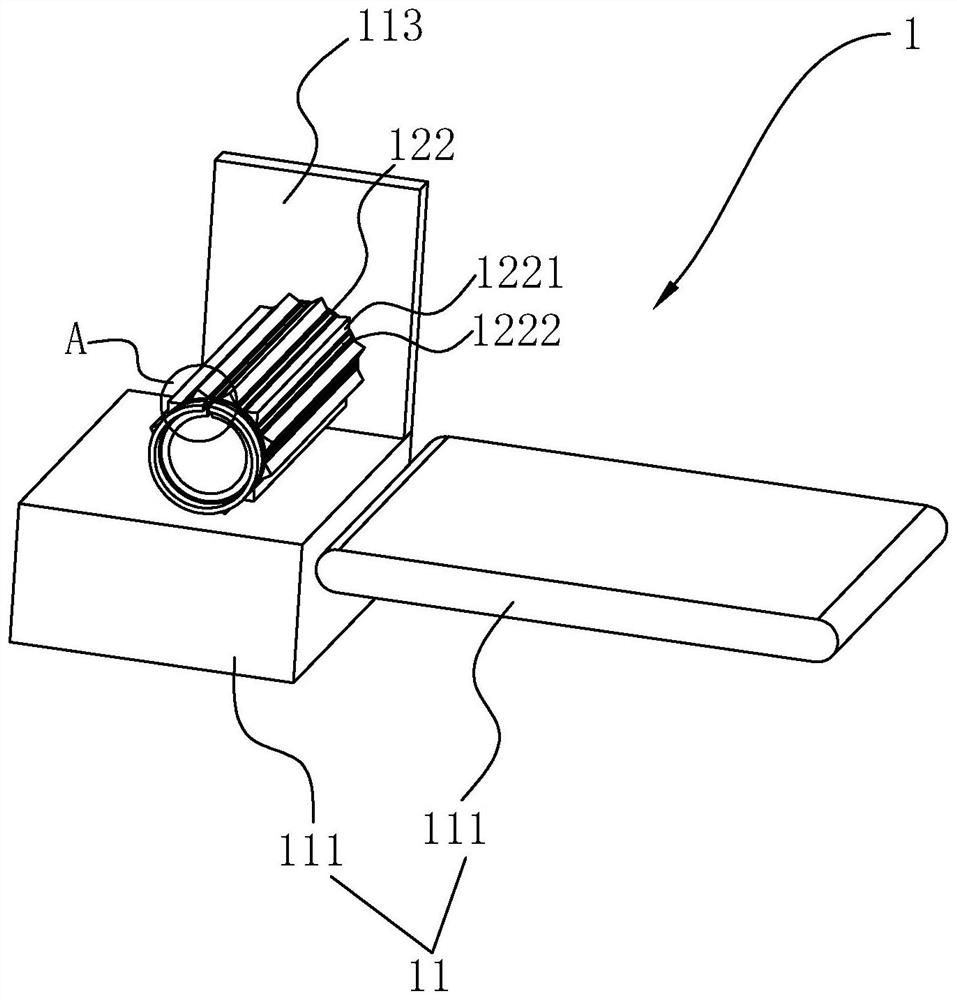

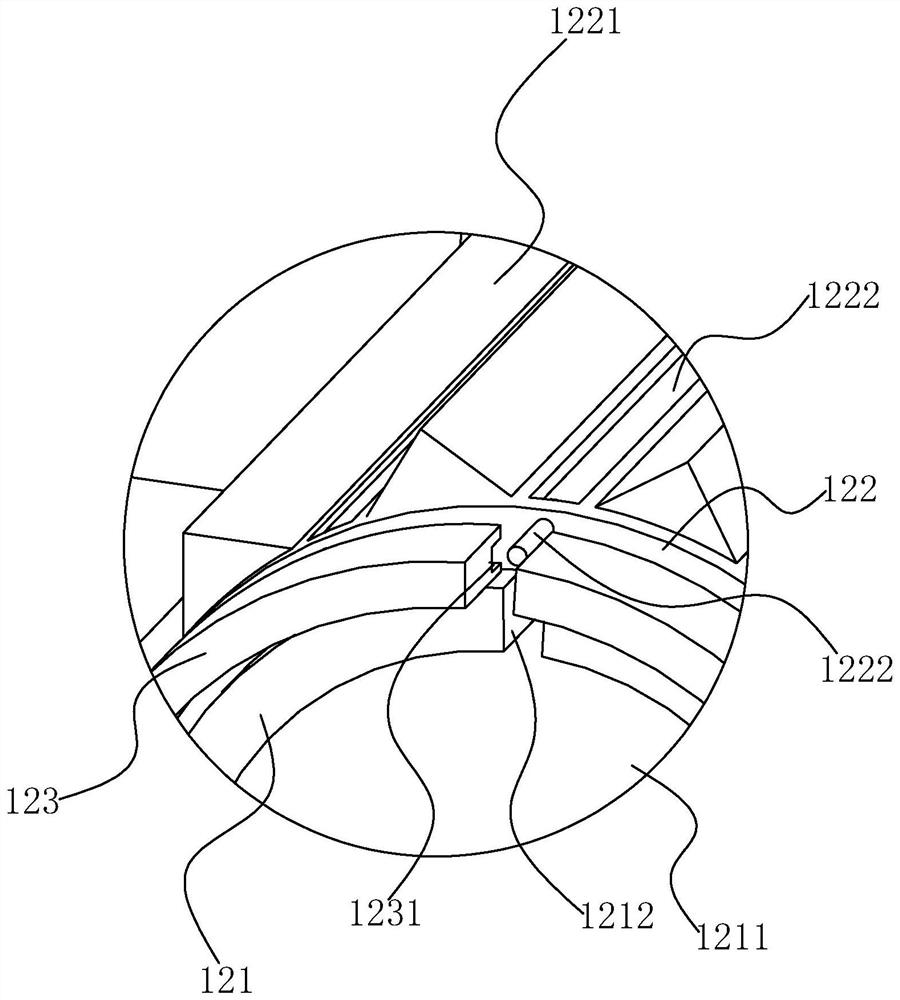

[0043] refer to Figure 1-Figure 7 , a far-infrared antibacterial heating cotton, including far-infrared fiber 1.5D50%, three-dimensional hollow 3D silicon 35% and Huvis 4D15%; far-infrared fibers are evenly distributed with nanoparticles capable of emitting infrared rays. A far-infrared antibacterial heating cotton, which uses far-infrared fibers to add nanoparticles, so that the surface area of the fibers is increased, and the surface activity and surface state adsorption, diffusion and other characteristics are significantly improved, so that the product has antibacterial and antibacterial functions, heat preservation and other functions. The next-to-body fiber can continue to absorb the far-infrared rays released by the human body, resonate absorption, and maintain temperature. The three-dimensional central control 3D and Huvis...

Embodiment 2

[0048] The embodiment of the present application discloses a far-infrared antibacterial heating cotton and its production and processing flow.

[0049] refer to Figure 1-Figure 7 , a far-infrared antibacterial heating cotton, including far-infrared fiber 1.5D50%, three-dimensional hollow 3D silicon 35% and Huvis 4D15%; far-infrared fibers are evenly distributed with nanoparticles capable of emitting infrared rays. A far-infrared antibacterial heating cotton, which uses far-infrared fibers to add nanoparticles, so that the surface area of the fibers is increased, and the surface activity and surface state adsorption, diffusion and other characteristics are significantly improved, so that the product has antibacterial and antibacterial functions, heat preservation and other functions. The next-to-body fiber can continue to absorb the far-infrared rays released by the human body, resonate absorption, and maintain temperature. The three-dimensional central control 3D and Huvis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com