Engine oil composition

A technology of engine oil and composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of increasing engine wear and affecting engine low-temperature starting performance, etc., and achieves good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

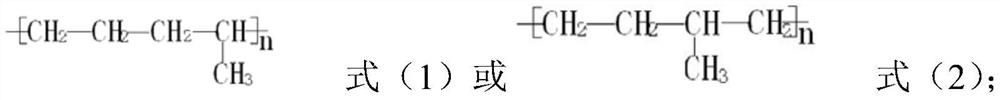

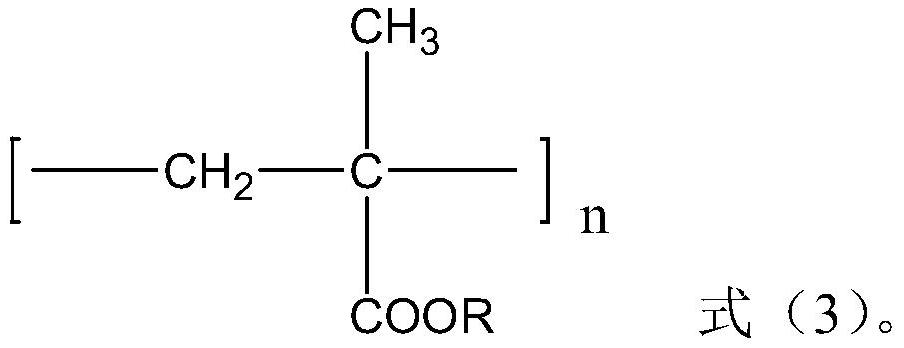

Method used

Image

Examples

Embodiment 1

[0029] Composition is made up of the composition of following weight percentage content:

[0030] Specific proportion of vinyl acetate-fumarate pour point depressant 0.1% by weight Salicylate / sulfonate compound detergent 2% by weight Polyisobutylene succinimide ashless dispersant 1.35% by weight Compound antioxidant (phenol type: amine type weight ratio = 1:1) 1.1% by weight Hydrogenated styrene-diene copolymer viscosity index improver 6.6% by weight Zinc Dialkyl Dithiophosphate 1.34% by weight Friction reducer MoDTC 0.03% by weight Any combination of 50N-500N neutral base oils of Group II, III, IV, V margin

[0031] Include in the vinyl acetate-fumarate pour point depressant of this specific ratio: the octal fumarate of 0.5 weight part, the lauryl fumarate of 1 weight part, the tetradecyl fumarate of 1 weight part ester, 1 part by weight of cetyl fumarate and 1 part by weight of stearyl fumarate.

[0032] The pr...

Embodiment 2

[0034] The composition is composed of the following components by weight percentage: the composition is composed of the following components by weight percentage:

[0035]

[0036]

[0037] Include in the vinyl acetate-fumarate pour point depressant of this specific ratio: the octal fumarate of 0.5 weight part, the lauryl fumarate of 1 weight part, the tetradecyl fumarate of 1 weight part ester, 1 part by weight of cetyl fumarate and 1 part by weight of stearyl fumarate.

[0038] Its preparation method is with embodiment 1.

Embodiment 3

[0040] The composition is composed of the following components by weight percentage: the composition is composed of the following components by weight percentage:

[0041]

[0042] Include in the vinyl acetate-fumarate pour point depressant of this specific ratio: the octal fumarate of 0.5 weight part, the lauryl fumarate of 1 weight part, the tetradecyl fumarate of 1 weight part ester, 1 part by weight of cetyl fumarate and 1 part by weight of stearyl fumarate.

[0043] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com