Flocking-imitating polypropylene composite material as well as preparation method and application thereof

A technology of composite materials and polypropylene, which is applied in the field of imitation flocking polypropylene composite materials and its preparation, can solve the problems of affecting consumers' visual and tactile experience, poor tactile sense, VOC rise, etc., so as to improve visual quality and reduce hardware Plastic feel, VOC reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

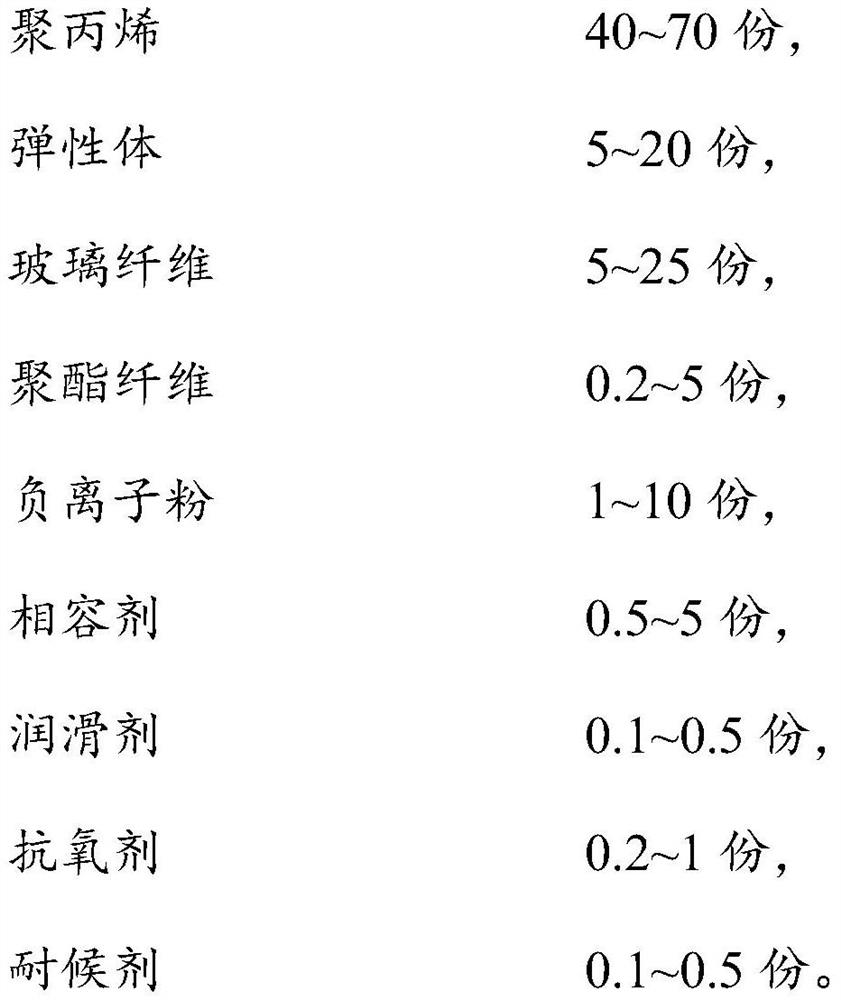

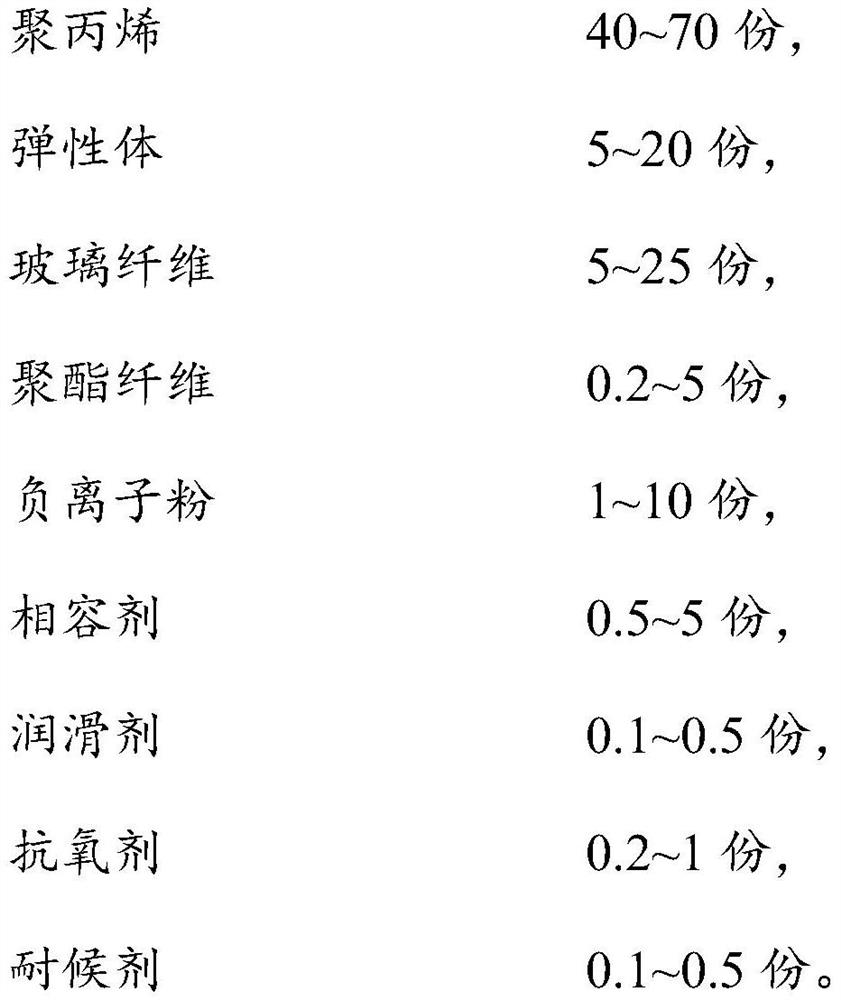

Method used

Image

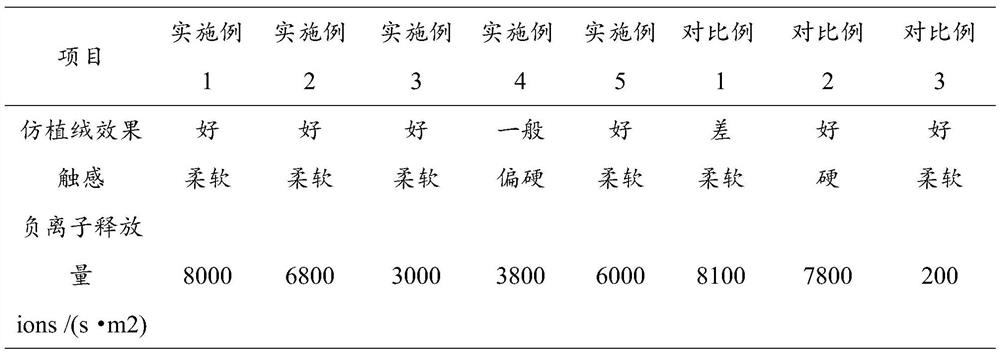

Examples

Embodiment 1

[0025] Take 40 parts of polypropylene BX3800, 20 parts of ethylene-propylene copolymer, 4 parts of polyester fiber with a length of 1 mm, 10 parts of negative ion powder with a particle size of 1200 mesh, 3 parts of PP-g-MAH (BONDYRAM 1001), 0.3 parts of hard Calcium fatty acid, 0.3 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.3 part of hindered amine light stabilizer 5590 are mixed evenly, and then added to the twin-screw extruder through the main feeding screw to melt, mix and disperse. Then add 20 parts of glass fibers with a length of 4mm through the side feeding screw, and then plasticize, extrude, and pelletize. °C, the screw speed is 400r / min.

Embodiment 2

[0027] Get 50 parts of polypropylene M60RHC, 15 parts of ethylene-hexene copolymer, 5 parts of polyester fibers with a length of 0.5 mm, 8 parts of negative ion powder with a particle size of 800 mesh, 4 parts of PP-g-MAH compatibilizer (BONDYRAM 1001 ), 0.1 part of erucamide, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, and 0.5 part of ultraviolet absorber 234 are mixed evenly, and then added to the twin-screw extruder through the main feeding screw barrel for melting, mixing, Disperse, and then add 15 parts of short glass fibers with a length of 3mm through the side feeding screw, and then undergo plasticization, extrusion, and granulation. Among them, the screw length-diameter ratio of the twin-screw extruder is 40:1. The temperature is 225° C., and the screw speed is 450 r / min.

Embodiment 3

[0029] Get 65 parts of polypropylene K7227H, 18 parts of ethylene-butylene copolymer, 2 parts of polyester staple fiber with a length of 2mm, 4 parts of particle diameter as 800 mesh negative ion powder, 2 parts of PP-g-MAH compatibilizer (BONDYRAM 1001 ), 0.2 part of stearic acid amide, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.2 part of ultraviolet absorber 327 after mixing evenly, join in the twin-screw extruder through main feeding screw barrel and carry out melting, mixing , disperse, and then add 10 parts of short glass fibers with a length of 2mm through the side feeding screw, and then undergo plasticization, extrusion, and granulation. Among them, the screw length-to-diameter ratio of the twin-screw extruder is 35:1. The outlet temperature is 180°C, and the screw speed is 200r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com