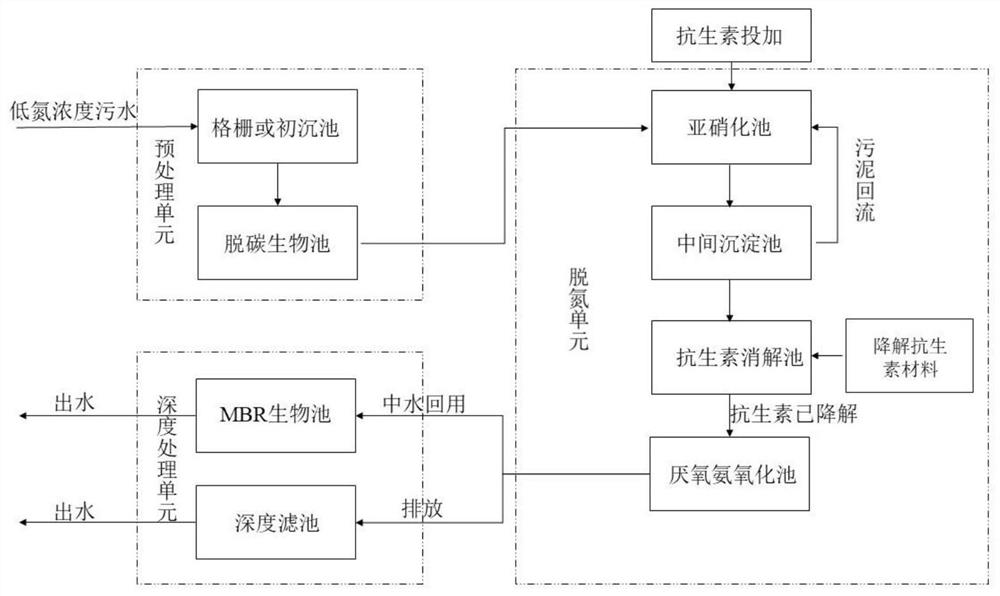

Low-ammonia-nitrogen-concentration sewage mainstream anaerobic ammonia oxidation system for limiting nitrifying bacteria through antibiotics and process thereof

A technology of anaerobic ammonium oxidation and limited nitrification, which is applied in the field of mainstream anaerobic ammonium oxidation process of low ammonia nitrogen concentration sewage, can solve the problems such as difficult control of nitrosation section, reduce energy consumption and chemical dosing costs, and reduce organic carbon load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Sewage ammonia nitrogen concentration 500-1000mg / L, COD concentration 300-500mg / L, SS 150-500mg / L

[0058] Sewage with low ammonia nitrogen concentration enters the mainstream anaerobic ammonium oxidation process. The specific process is as follows: sewage enters the pretreatment system, and the grille intercepts large suspended particles. Then it enters the activated sludge decarbonization biological tank and stays for 20 hours, 80% of COD is removed, and the COD concentration of the effluent of the pretreatment unit is 60-100mg / L. Since there is no carbon source and alkalinity dosing in the pretreatment unit, 10% of ammonia nitrogen is removed. The concentration of ammonia nitrogen in the effluent of the pretreatment unit is 450-900mg / L. Enter the nitrosation tank, and put in 1mg / L antibiotics (including but not limited to oxytetracycline, metronidazole, furazolidone, gentamicin, etc.), and the hydraulic retention time is 20 hours. 50% of ammonia nitrogen is convert...

Embodiment 2

[0060] The concentration of ammonia nitrogen in sewage is 300-500mg / L, the concentration of COD is 300-500mg / L, and the concentration of SS is 150-500mg / L.

[0061] With example 1, the difference is that the hydraulic retention time of the nitrosation tank is 10 hours, and the hydraulic retention time of the anaerobic ammonium oxidation tank is 5 hours.

Embodiment 3

[0063] The concentration of ammonia nitrogen in sewage is 300-1000mg / L, the concentration of COD is 100-300mg / L, and the concentration of SS is 150-500mg / L.

[0064] With example 1 or example 2. The difference is that the hydraulic retention time of the activated sludge decarbonization biological pool is shortened to less than 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com