Self-circulation dust removal chamber for environmental protection engineering and application method thereof

A self-circulating, environmental protection engineering technology, applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, chemical instruments and methods, etc., can solve the inability to achieve full-body cleaning, the impact of the environment and the physical and mental health of workers, and dust collectors Clean up problems such as limited angles to achieve the effect of improving dust removal efficiency, improving dust efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

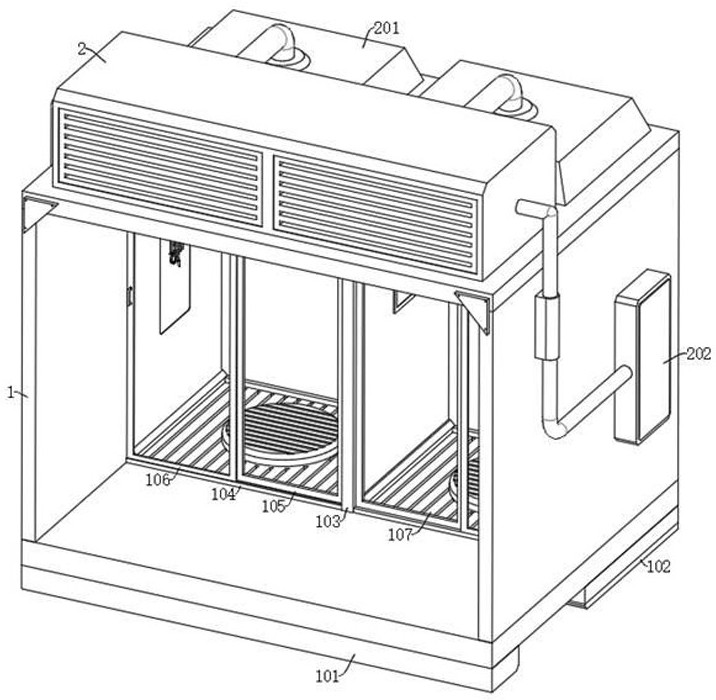

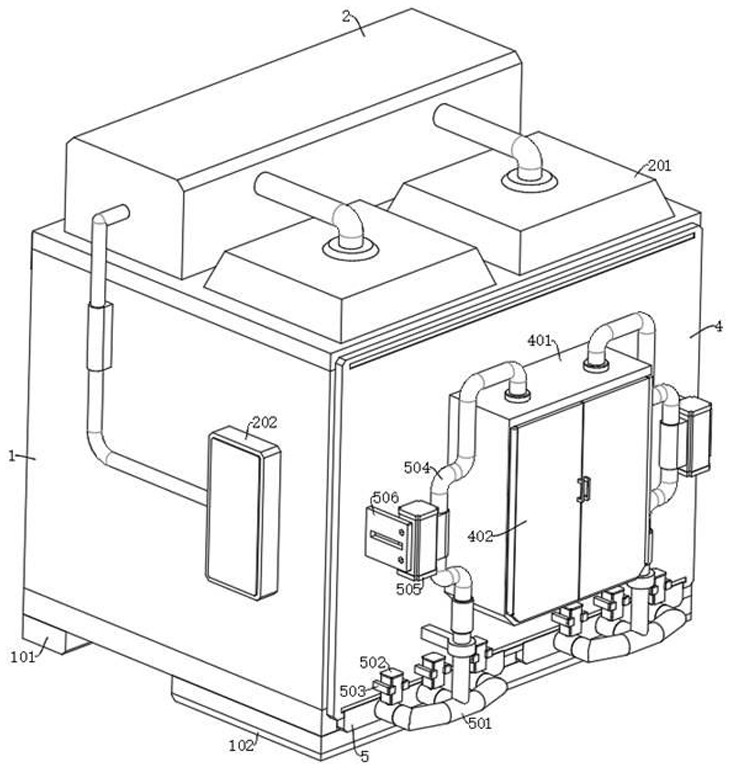

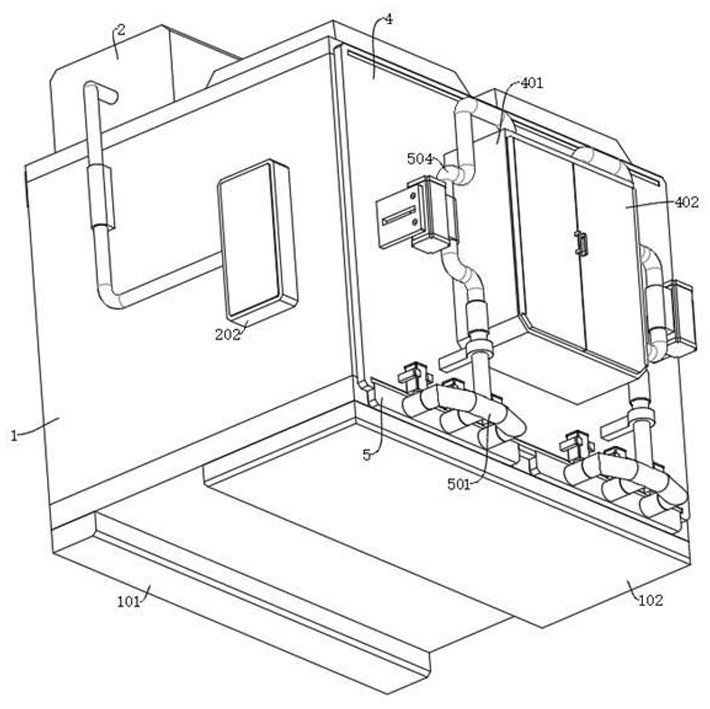

[0038] see Figure 1-Figure 8 , the present invention provides the following technical solutions:

[0039] A self-circulating dust removal chamber for environmental protection engineering, comprising:

[0040] The dust removal chamber main body 1, the bottom inner wall of the dust removal chamber main body 1 is symmetrically provided with two dust removal grooves;

[0041] The air jet dedusting assembly, the air dedusting assembly includes an air pump 2 and two dust removal seats 201, the air pump 2 is fixedly connected to the upper end of the dust removal chamber main body 1, and the two dust removal seats 201 are all arranged on the upper part of the dust removal chamber main body 1, the two dust removal seats 201 and The air pumps 2 are communicated through pipelines;

[0042] A partition 103, the partition 103 is fixedly connected to the upper and lower inner walls of the main body 1 of the dust removal chamber, and the inner walls of the two dust removal tanks are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com