Novel process route and system for flue gas purification in hazardous waste disposal

A flue gas purification system and hazardous waste technology, applied in the direction of climate change adaptation, combined devices, climate sustainability, etc., can solve the problems of air flow direction affecting dust removal effect, increased failure rate of processing equipment, low processing efficiency, etc., to achieve Increased efficiency, reduced operating costs, and reduced dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

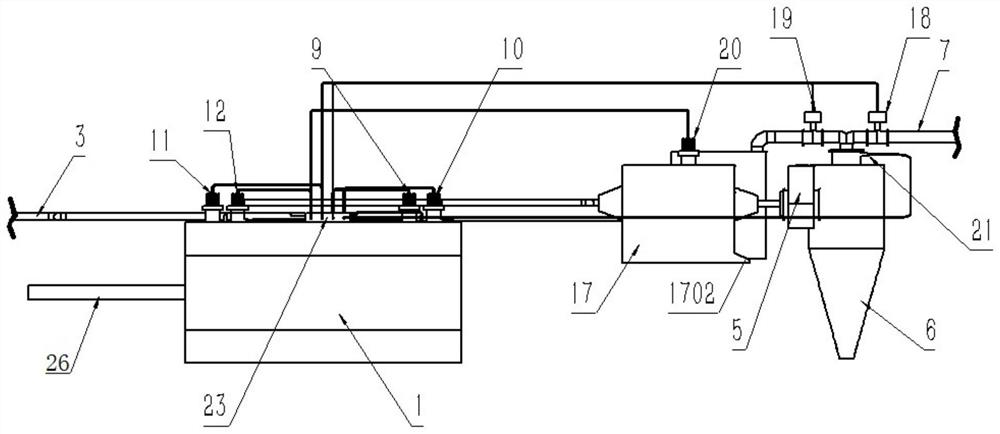

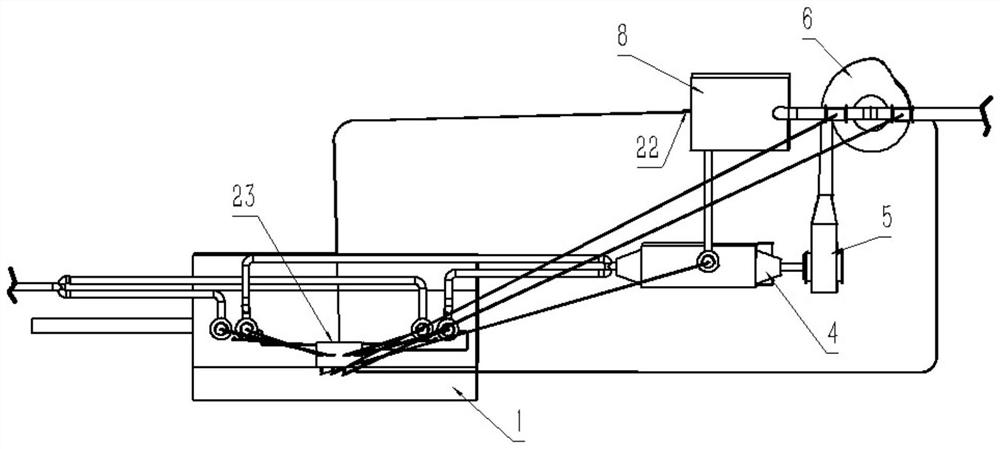

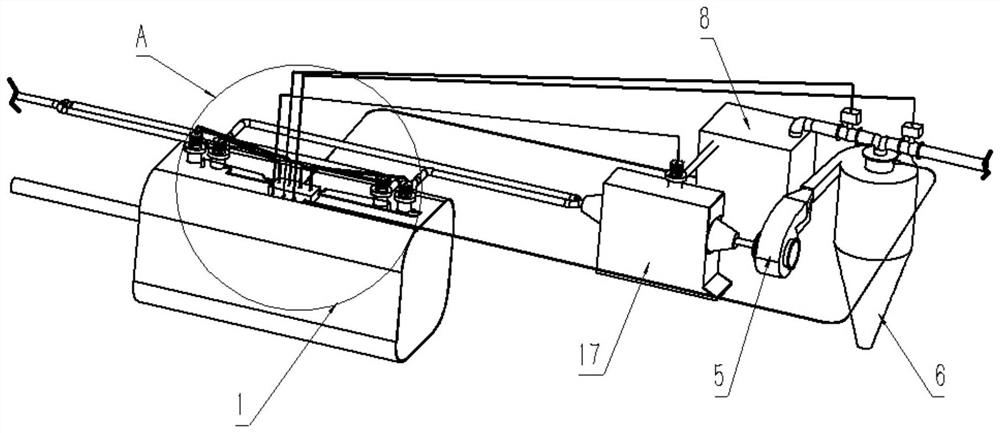

[0049] In order to clearly describe the technical characteristics of the present plan, the plan will be described below by way of example.

[0050] See Figures 1 to 7 As shown, the present invention is a hazardous waste disposal of flue gas purification process route and system, and is effectively improved the processing effect of the cyclone dust collector for pretreatment of flue gas into the cyclone collector.

[0051] Hazardous waste disposal flue gas purification new process route includes the following steps:

[0052] Step S1: Collect the smoke into the vacuum collection box 1, when the pressure is at the same pressure in the box, turn off the inlet valve, physical compression to the flue gas to improve the concentration of the flue gas;

[0053] Step S2: When the compressed flue gas concentration satisfies the setting standard, stop the compression and exterior exhaust gas, the discharge flue gas is sprayed to increase the mutual cohesive effect of the particulate matter in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com