Salt-reduced soy sauce with typical Cantonese soy sauce flavor and production method thereof

A production method and technology for soy sauce, applied in the direction of food science and the like, can solve the problems of difficulty in obtaining salt-reduced soy sauce, weak flavor of soy sauce, and high requirements for process control level, so as to shorten the low-salt fermentation period, improve the umami and quality, Good flavor coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A typical soy sauce flavor widely reduced salt soy sauce production process, comprising the steps of:

[0093] S1: Preparation of soy koji: 1) Soybean processing: cleaning, after cleaning, at room temperature (28-32 deg.] C, 2h soak the same applies hereinafter), so moisture control in about 50%, and then by evaporation ball 0.1MPa , 121 deg.] C and the cook 8min, cooled standby; 2) soybean koji: steamed soybeans mixed with the cooled wheat flour, the ratio of 0.2% of the mixture mass (w / w) of the access Huniang 3.042 m koji Aspergillus (viable cell count of 4 × 10 10 A / g), into the pool of music, open circulating air, controlling the temperature of about 32 ℃, time 42h koji, soy koji obtained;

[0094] S2: Preparation of fermented moromi: Take soy koji, was added 1.2 (w / w) saline, 15 Baume brine concentration, 25 deg.] C dew natural drying 2.5 months fermentation, the fermentation process timing cycle drench;

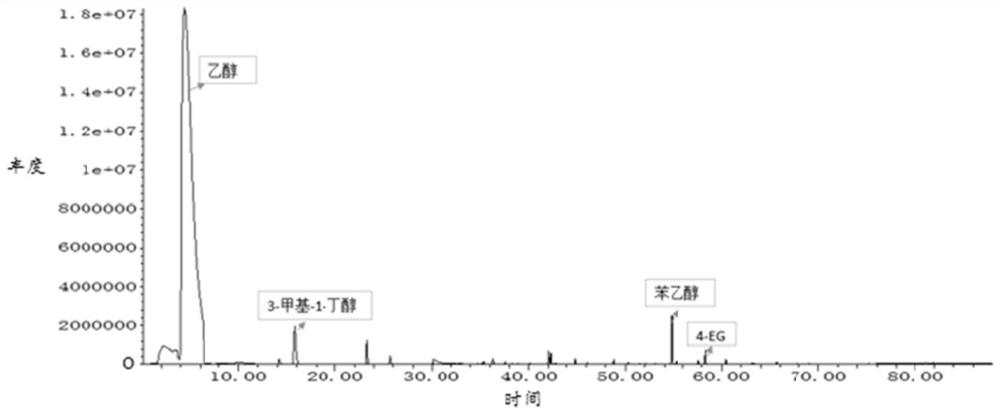

[0095] S3: Preparation of fermentation broth flavor Whea...

Embodiment 2

[0102] A typical soy sauce flavor widely reduced salt soy sauce production process, comprising the steps of:

[0103] S1: Preparation of soy koji: 1) Soybean processing: cleaning, after washing, soaked at about room temperature 2h, so moisture control at 50% and then distilled off by ball 0.1MPa, 121 ℃ the cook 8min, cooled, alternate; 2) soybean koji: steamed soybeans mixed with the cooled wheat flour, the proportions by mass of mixture 0.2% (w / w) of the access Huniang seed koji of Aspergillus 3.042 m (viable cell count of 4 × 10 10 A / g), into the pool of music, open circulating air, controlling the temperature 32 ℃, time 42h koji, soy koji obtained;

[0104] S2: Preparation of fermented moromi: Take soy koji, was added 1.2 (w / w) saline, saline at a concentration of 15 Baume, 25 deg.] C dew natural drying 2.5 months fermentation, the fermentation process timing cycle drench;

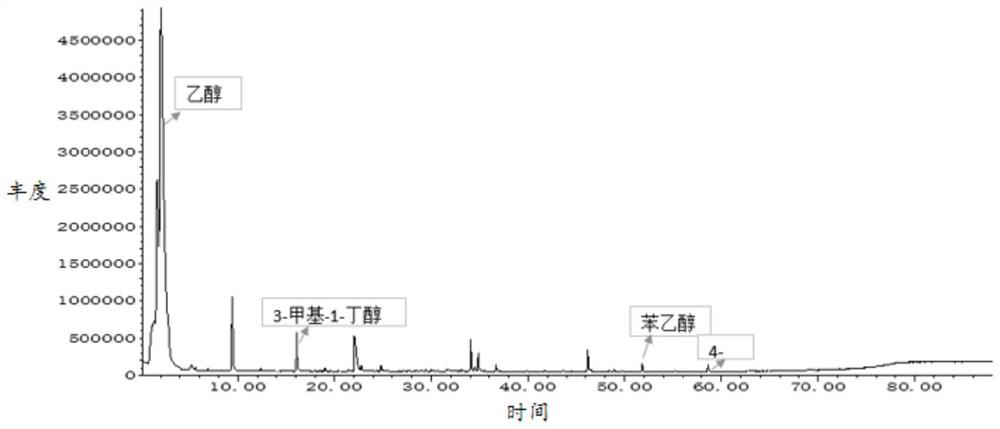

[0105] S3: Preparation of fermentation broth flavor Wheat: Wheat raw frying at 300 ℃ 2min, cooled ...

Embodiment 3

[0112] A typical broad-type soy sauce flavor production method, including the following steps:

[0113] S1: Soybeancraft Preparation: 1) Soybean Treatment: Induceration, after cleaning, soak for 2 h at room temperature, so that the moisture is controlled around 50%, then vapor the ball at 0.1 MPa, 121 ° C for 8 min, cool, Spare; 2) Soybean Survey: Mix the steamed cooled soy and wheat flour 10 A / g), sent into the car, open the circulating wind, the control temperature is about 32 ° C, the curved time is 42h, resulting in soybean curves;

[0114] S2: Fermented sauce preparation: Take a soybean curvature, add 1.2 (w / w) double salt water, salt water concentration 15 Popularity, 25 ° C naturally exposure fermentation 2.5 months, the fermentation process is timed during the fermentation;

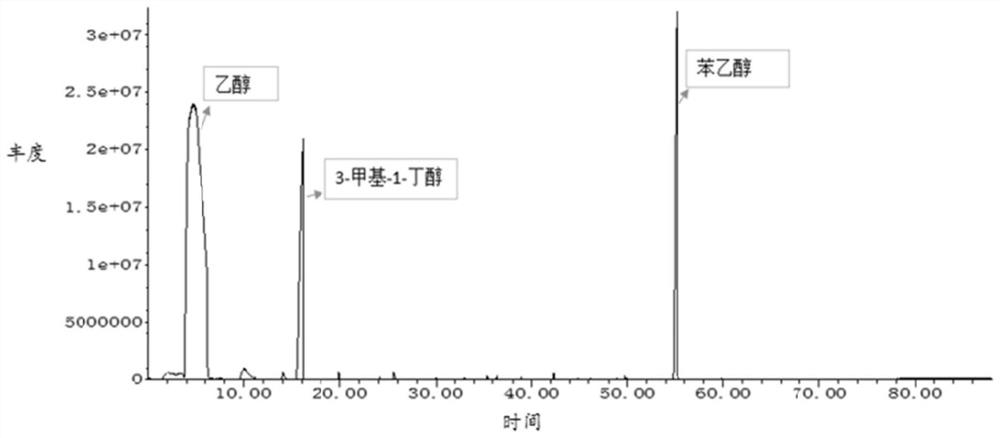

[0115] S3: Wheat Flavor Fermentation Hydram: Take 2.75 times (w / W) water, increase the temperature to 95 ° C, and add high-temperature amylase during heating, heat insulation reaction 1.5H, iodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com