Heat preservation type building board with high bearing capacity

A technology of bearing capacity and building boards, applied in building insulation materials, heat preservation, construction, etc., can solve the problems of poor insulation effect of building boards, and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

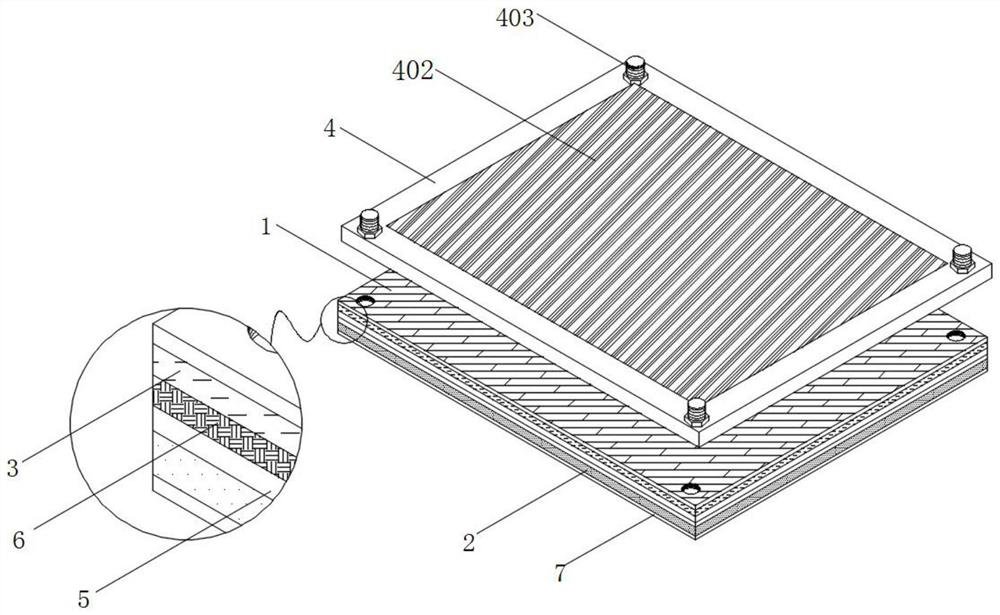

[0046] see figure 1 and Figure 9 , an embodiment provided by the present invention: a thermal insulation building board with strong bearing capacity, including an outer panel 1, a thermal insulation panel 2 and an anti-compression panel 6, the bottom of the outer panel 1 is equipped with an anti-crack panel 3, and The bottom of 3 is equipped with anti-pressure plate 6;

[0047] The inner walls of both sides of the anti-pressure plate 6 are provided with circular grooves 601 and bar-shaped grooves 605, and the bar-shaped grooves 605 are symmetrically arranged up and down with respect to the circular grooves 601, and the inside of the circular grooves 601 is fitted with reinforcing ribs 602, and the two sides of the reinforcing ribs 602 The upper and lower symmetrically arranged compression springs 603 are installed on the end surfaces, and the limit block 604 is installed at the opening of the bar groove 605, and the height of the limit block 604 is smaller than the depth of ...

Embodiment 2

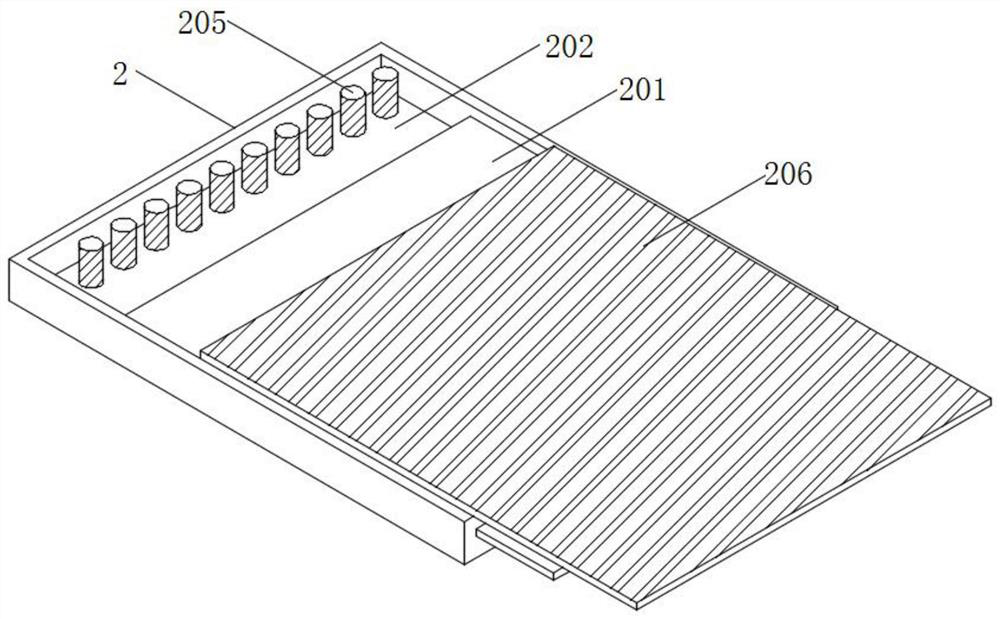

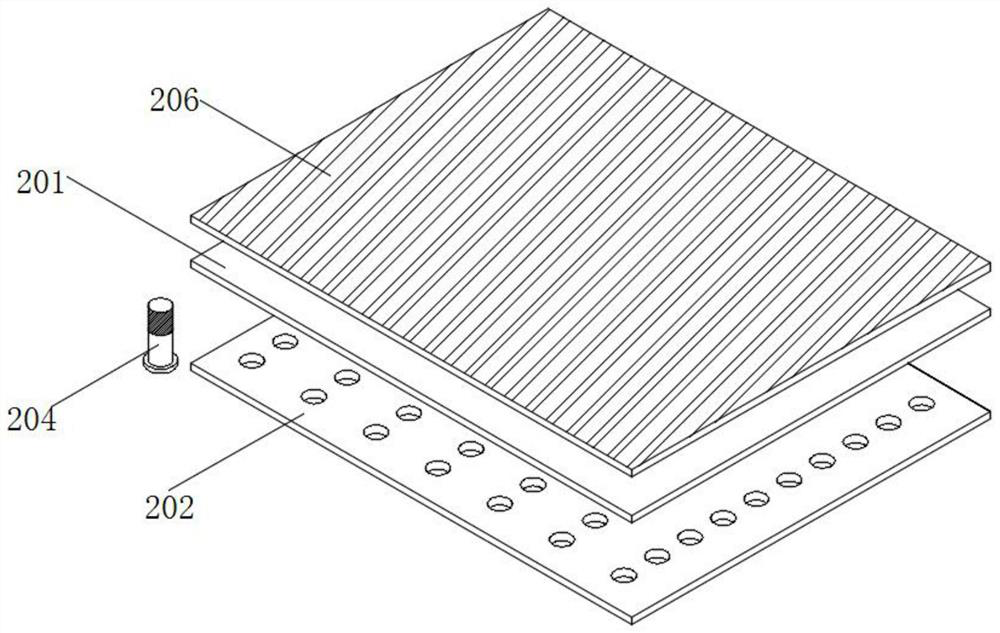

[0052] see Figure 1-Figure 4 , an embodiment provided by the present invention: a heat-insulating building board with strong bearing capacity, including an outer plate 1 and a heat-insulating board 2, a heat-insulating plate 5 is installed at the bottom of the pressure-resistant plate 6, and a heat-insulating plate 5 is installed at the bottom of the heat-insulating plate There is a thermal insulation board 2, the bottom of the thermal insulation board 2 is an open design, and the inside of the thermal insulation board 2 is fitted with a heating plate 201 and a No. The inside of the plate 2 is fitted with a No. 1 heat shield 202, and the inside of the No. 1 heat shield 202 is slidingly connected with an expansion strip 204. The top of the expansion strip 204 is equipped with a heat conduction rod 205, and the top of the heat conduction rod 205 is connected to the heating plate 201. The bottom of the expansion bar 204 is installed with a limit heat insulation block 203, and th...

Embodiment 3

[0057] see figure 1 and Figure 7 , an embodiment provided by the present invention: a thermal insulation building board with strong bearing capacity, including an outer frame 4, the top four corners of the outer board 1 are provided with threaded holes, the inner threads of the threaded holes are connected with connecting bolts 403, the outer The top of the board 1 is detachably connected to the outer frame 4 through the connecting bolt 403, the top of the outer frame 4 is provided with a groove, the inside of the groove is installed with a solar panel 401, and the solar panel 401 is electrically connected with the heating plate 201, and the groove A water baffle 402 is installed on the top wall of the top wall, and the water baffle 402 is located inside the four sets of connecting bolts 403 .

[0058] Specifically, through the connecting bolts 403, the outer frame 4 and the outer panel 1 can be in a detachable installation state, so that the user can use the board as a buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com