Building coating with high rain mark resistance and preparation method thereof

A technology for architectural coatings and rain resistance, applied in the direction of coatings, etc., can solve the problems of poor rain marks, floating color, poor compatibility of water-based coating systems, etc., and achieve the effect of improving the performance of rain marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A kind of high anti-rain mark architectural coating is prepared by the following method:

[0072] First add emulsion, water, 1 / 2 (weight) defoamer, wetting agent, dispersant, cellulose, PH value regulator, antifreeze into the dispersion tank, stir well under the state of 300-400rpm, and then Add titanium dioxide, calcium carbonate, kaolin and calcium silicate, disperse at 1200-1500rpm for 20 minutes until the fineness is ≤60 microns, then add film-forming aids, 1 / 2 (weight) defoamers, preservatives and polyurethane thickeners The agent is stirred evenly, and the viscosity is adjusted to obtain the coating.

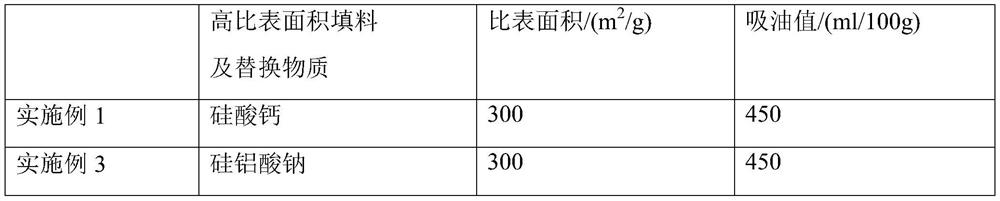

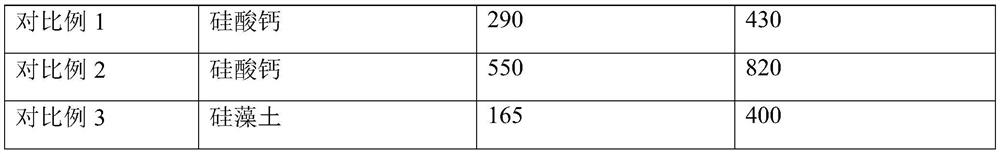

[0073] Among them, the specific surface area of calcium silicate is 300m 2 / g, the oil absorption value is 450ml / 100g. The content of each component is shown in Table 1, and the unit of the content of each component is kg.

Embodiment 2

[0075] The difference from Example 1 is that calcium silicate and calcium silicate are added in different amounts, and the specific amounts are shown in Table 1.

Embodiment 3

[0077] The difference from Example 1 is that the calcium silicate is replaced by sodium aluminosilicate of equal weight, and the specific surface area and oil absorption value of sodium aluminosilicate are equivalent to those of calcium silicate in Example 1. The parameters of specific specific surface area and oil absorption value are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com