Magnetic suspension vacuum pipeline carrying system

A vacuum pipeline and magnetic levitation technology, which is applied in the field of transportation pipelines, can solve the problems of low transportation efficiency and difficulty in increasing the speed, and achieve the effects of saving energy, speeding up energy consumption, and reducing the laying length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

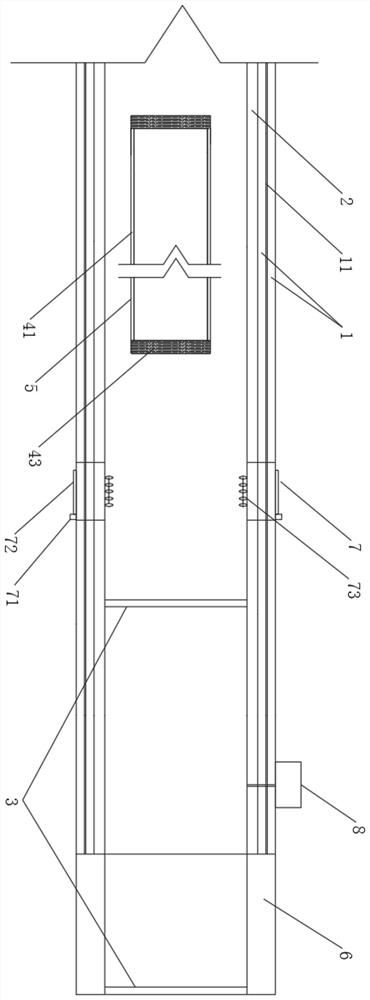

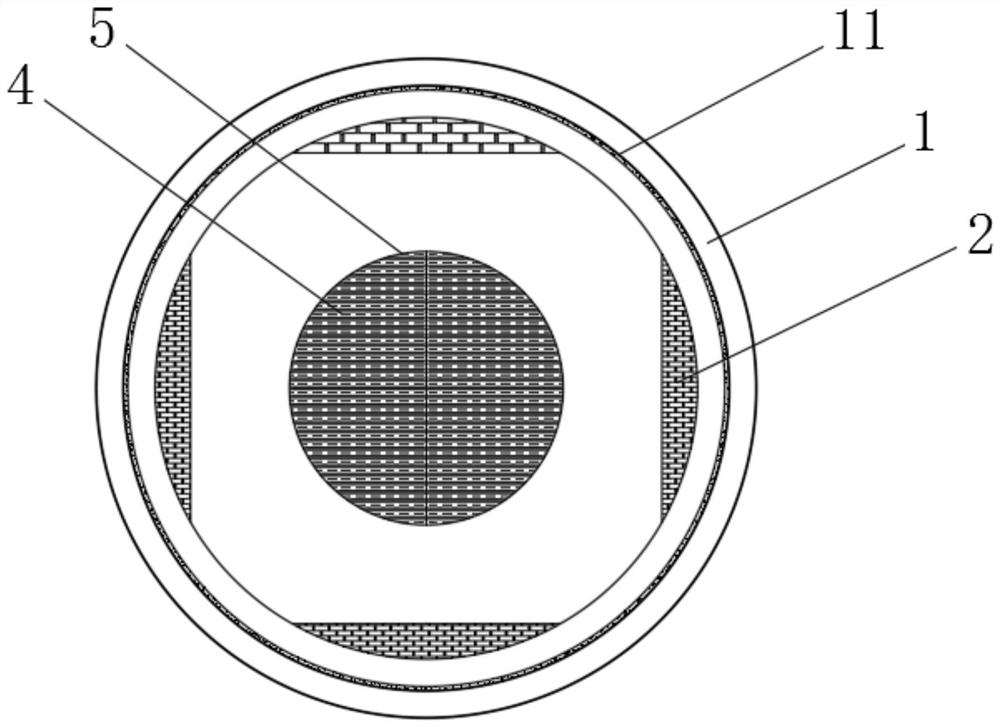

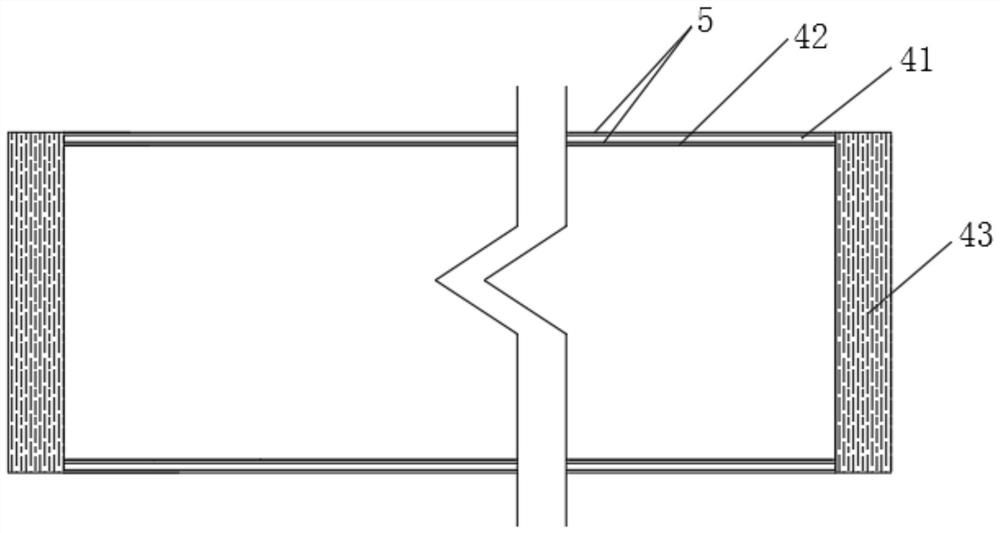

[0048] Such as Figure 1-5 As shown, a magnetic levitation vacuum pipeline carrying system includes at least one vacuum pipeline 1, a No. 1 permanent magnet 2 arranged on the inner wall of the vacuum pipeline 1, pipeline closing doors 3 respectively arranged at both ends of the vacuum pipeline 1, and arranged in the vacuum pipeline 1 The transportation carrier 4, the No. 2 permanent magnet 5 arranged on the transportation carrier 4, and the optical drive engine accelerator 7 and / or Gauss accelerator 6 arranged in the vacuum pipeline 1;

[0049] Under the mutual repulsion of the No. 1 permanent magnet 2 and the No. 2 permanent magnet 5, the transportation vehicle 4 is suspended in the center of the vacuum pipeline 1, and the optical drive engine accelerator 7 and / or Gauss accelerator 6 accelerates the transportation vehicle 4 to move , and when the magnetic field position of the No. 1 permanent magnet 2 changes (changing the current passed into the winding of the No. 1 permanen...

Embodiment 2

[0063] Such as Image 6 As shown, in order to facilitate maintenance, the magnetic levitation vacuum pipeline carrying system of the present invention also includes a magnetic levitation track 9 and a maintenance carrier 10 arranged on the top of the vacuum pipeline 1, the magnetic levitation track 9 is provided with a fixed permanent magnet, and the maintenance carrier 10 There is a suspended permanent magnet on it, and the maintenance carrier 10 is suspended on the magnetic levitation track 9 through the mutual repulsion of the fixed permanent magnet and the suspended permanent magnet. The maintenance carrier 10 is used to transport the single-section vacuum pipeline 1 to the damaged vacuum pipeline 1. Parts, rapid repair and replacement work.

[0064] And in order to protect the contents of the carrier, the maintenance carrier 10 adopts a vacuum layer structure for heat preservation. Through the fulcrum, a vacuum layer is created to achieve the purpose of heat preservation...

Embodiment 3

[0066] The application direction of a magnetic levitation vacuum pipeline delivery system described in Example 1:

[0067] The magnetic levitation vacuum pipeline carrying system is used for long-distance rail transportation of personnel and materials. In this embodiment, the No. 1 permanent magnet 2 includes three strip-shaped magnetic poles N poles respectively arranged at the bottom and both sides of the inner cavity of the vacuum pipeline 1, see details Figure 7 .

[0068] It should be noted that the application of the magnetic levitation vacuum pipeline transportation system in long-distance rail transportation can greatly save the use of energy. Under vacuum conditions, the transportation vehicle 4 can maintain high-speed operation for a long time, and consumes a lot of energy. Low. Since the transport carrier 4 is floating in the vacuum pipeline 1, and there are mutually repulsive magnetic poles at both ends to maintain the left and right balance of the carrier, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com