Soft and hard combined fly ash carbon content on-line monitoring method

A technology combining fly ash carbon content, soft and hard, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unsatisfactory, laborious detection results, time-consuming, etc., to ensure uninterrupted output and fast response Cycle, the effect of strong promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

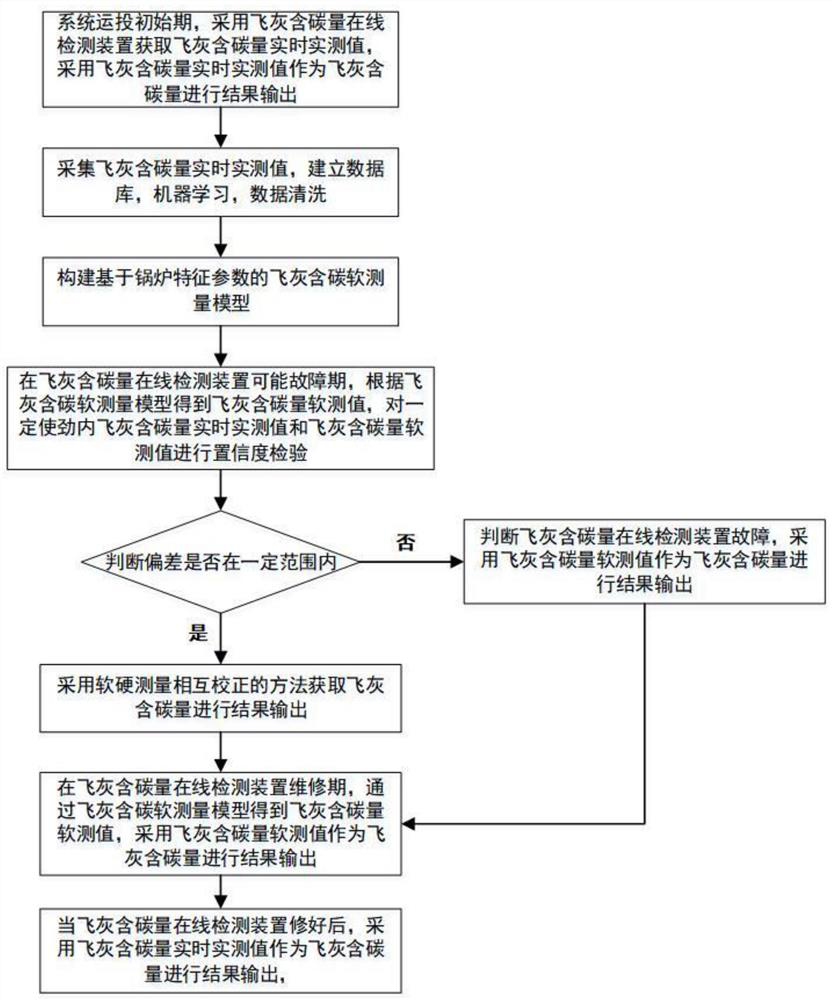

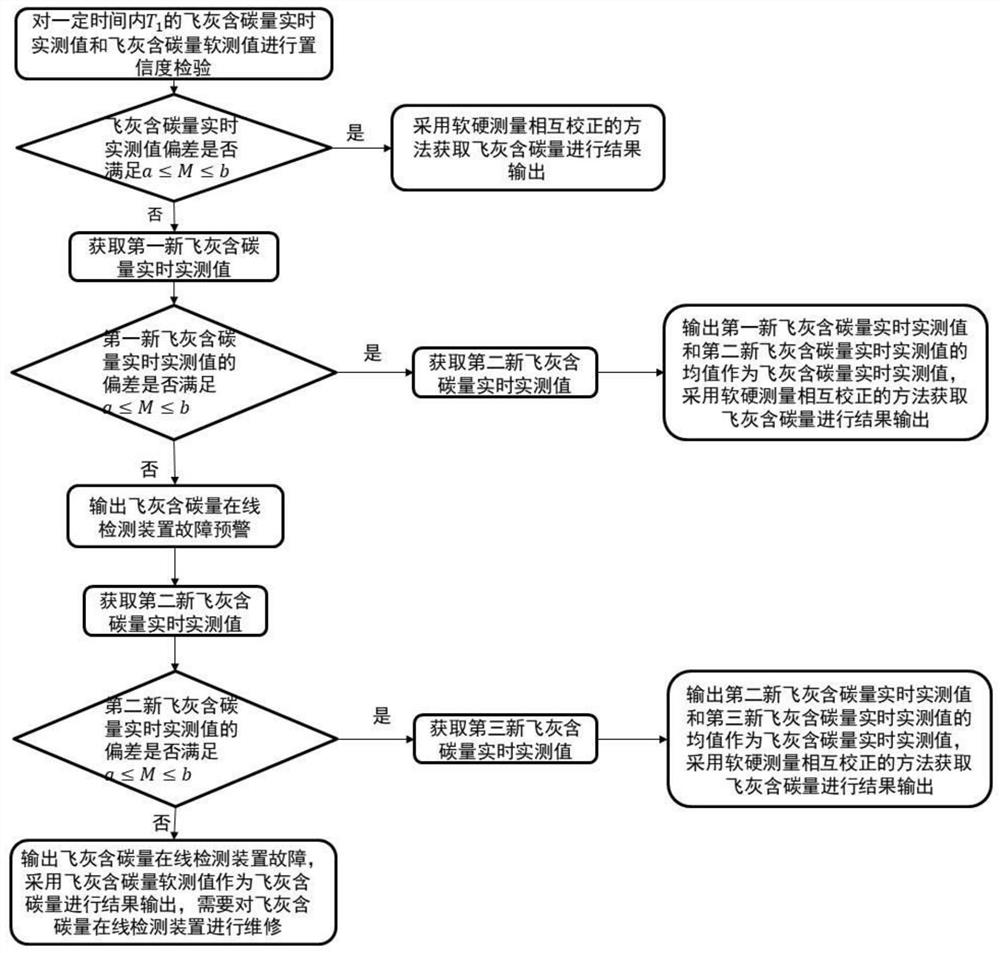

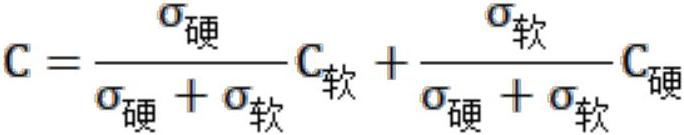

[0040] A method for on-line monitoring of carbon content in fly ash combined with soft and hard, such as figure 1 and figure 2 shown, including;

[0041] Step 1. In the initial stage of system operation, real-time carbon content detection of fly ash in the ash tube of coal-fired power station is carried out through the fly ash carbon content online detection device, and the real-time measured value of fly ash carbon content is obtained. At this time, the fly ash carbon content is used The real-time measured value of carbon content in ash is output as the carbon content of fly ash;

[0042] Step 2. The computer collects the real-time measured value of the carbon content of the fly ash, establishes a database, performs machine learning on the database, performs data cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com