Method for detecting synchronous vibration parameters of high-speed rotary blade under constant speed

A technology of synchronous vibration and high-speed rotation, which is applied in the direction of vibration measurement in solids, measuring vibration, measuring devices, etc., to simplify the measurement process and meet the effect of real-time online monitoring

Active Publication Date: 2011-01-05

ZHEJIANG ZHONGXIN POWER MEASUREMENT & CONTROL TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above synchronous vibration detection methods need to operate at a uniform speed of the rotating machinery as a prerequisite, which has certain limitations.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

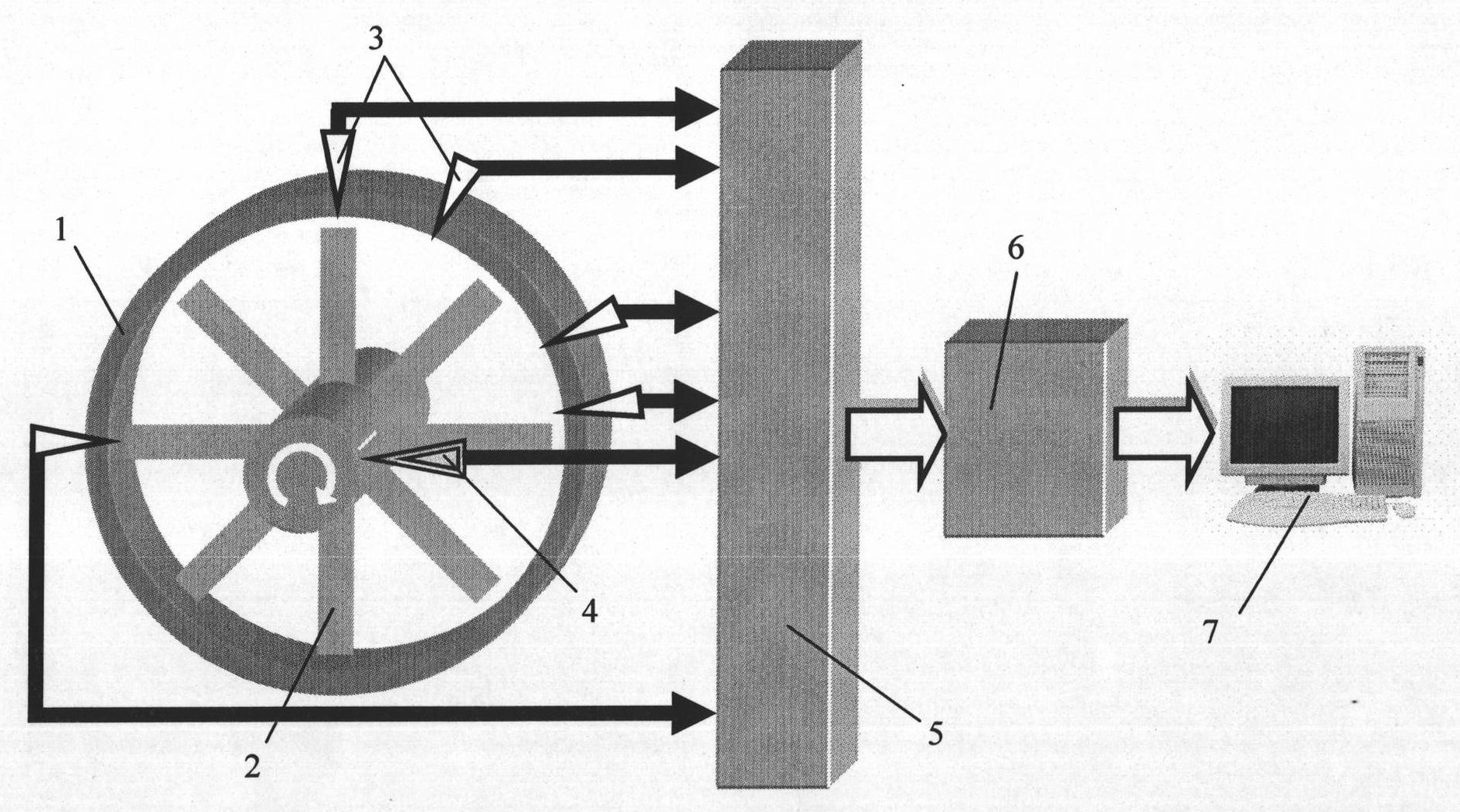

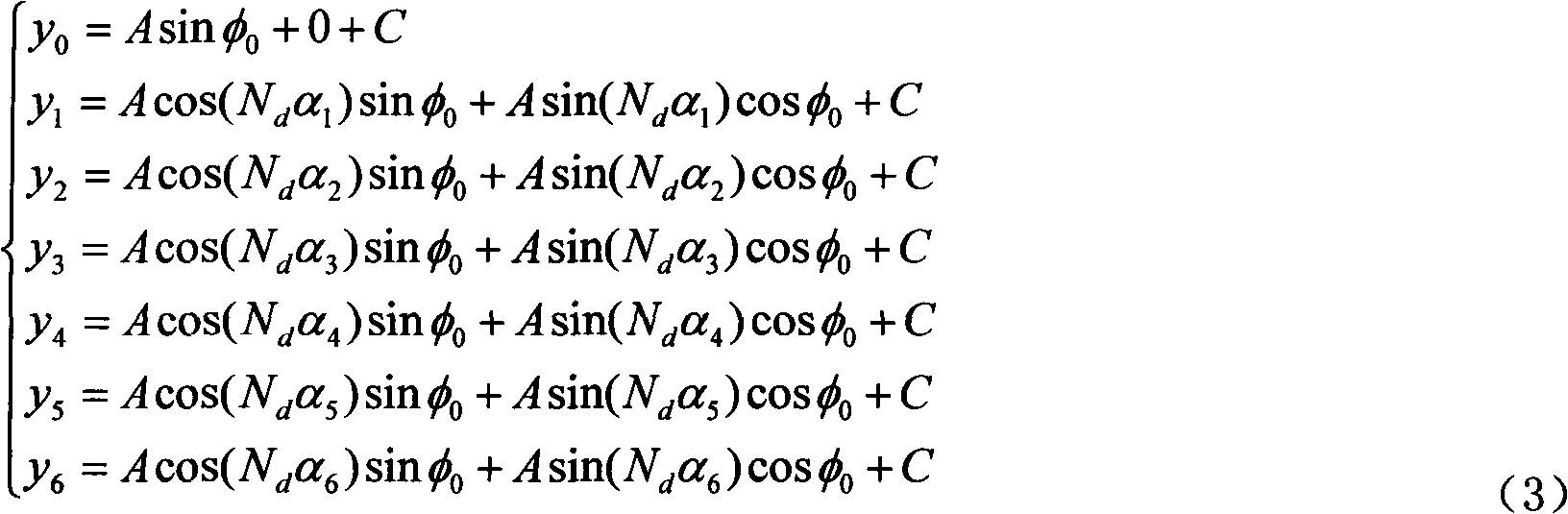

The invention relates to a method for detecting vibration of a blade of a rotary machine, in particular to a method for detecting synchronous vibration parameters of a high-speed rotary blade under a constant speed. In order to eliminate limitation of taking uniform variable speed running as a precondition and meet the demand of real-time online monitoring, the invention adopts the technical scheme that based on a bladetip timing vibration detection principle, the synchronous vibration displacement yi of a certain blade, detected by a bladetip timing sensor, is indicated as following: yi=Asin(Nealphai+Phi0)+C(i=0,1,2...). A frequency doubling traversal range containing actual synchronous vibration frequency doubling Ne of the blade is selected, and then an actual installing included anglealphai of the bladetip timing sensor and the selected frequency doubling Nej are substituted into the formula so as to work out the vibration displacement of different frequency doubling corresponding to a multiple-sensor theory measured by a least square method; the square and the radix of an error between the calculated vibration displacement and the vibration displacement of actual measurementare worked out, and the frequency doubling of the minimum value of the square and the radix of the error is taken as the frequency doubling value of the actual vibration of the blade in a frequency doubling traversal process. The invention is mainly applied to the method for detecting the vibration of the blade of the rotary machine.

Description

Detecting Method of Synchronous Vibration Parameters of High Speed Rotating Blades at Constant Speed technical field The present invention relates to a method for detecting the vibration of rotating mechanical blades, more specifically, the present invention relates to a method for detecting synchronous vibration parameters of high-speed rotating blades with random distribution of multi-sensors under the condition of constant speed based on the blade tip timing principle. Background technique Blade tip timing vibration measurement technology plays an important role in the field of real-time monitoring and fault diagnosis of rotating machinery. Higher requirements are put forward, which prompts it to develop in the direction of high-precision and comprehensive parameter detection. The blade tip timing vibration measurement technology is a non-contact detection method. Its basic principle is to install the blade tip timing sensor on the relatively stationary shell of the r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01H13/00G01H1/00

Inventor 段发阶李孟麟欧阳涛孔祥洪

Owner ZHEJIANG ZHONGXIN POWER MEASUREMENT & CONTROL TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com