Curved surface earthenware brick curtain wall dry hanging structure and construction technology

A ceramic brick and curtain wall technology, which is applied in the field of dry-hanging structure and construction technology of curved ceramic brick curtain wall, can solve the problems such as inability to solve the curved surface effect and poor effect, and achieve the effect of good practicability, simple structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

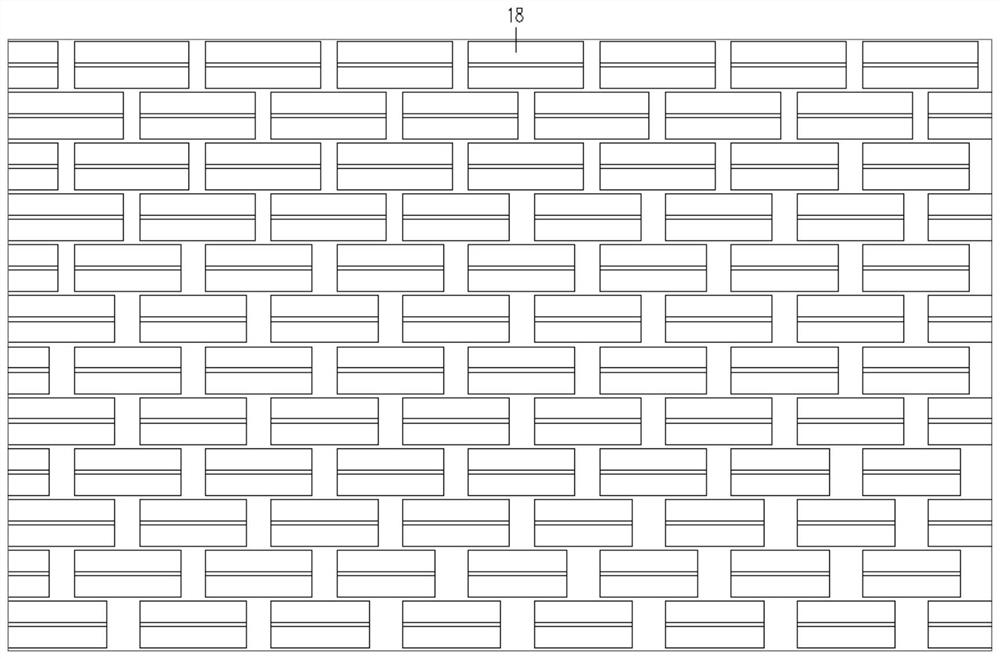

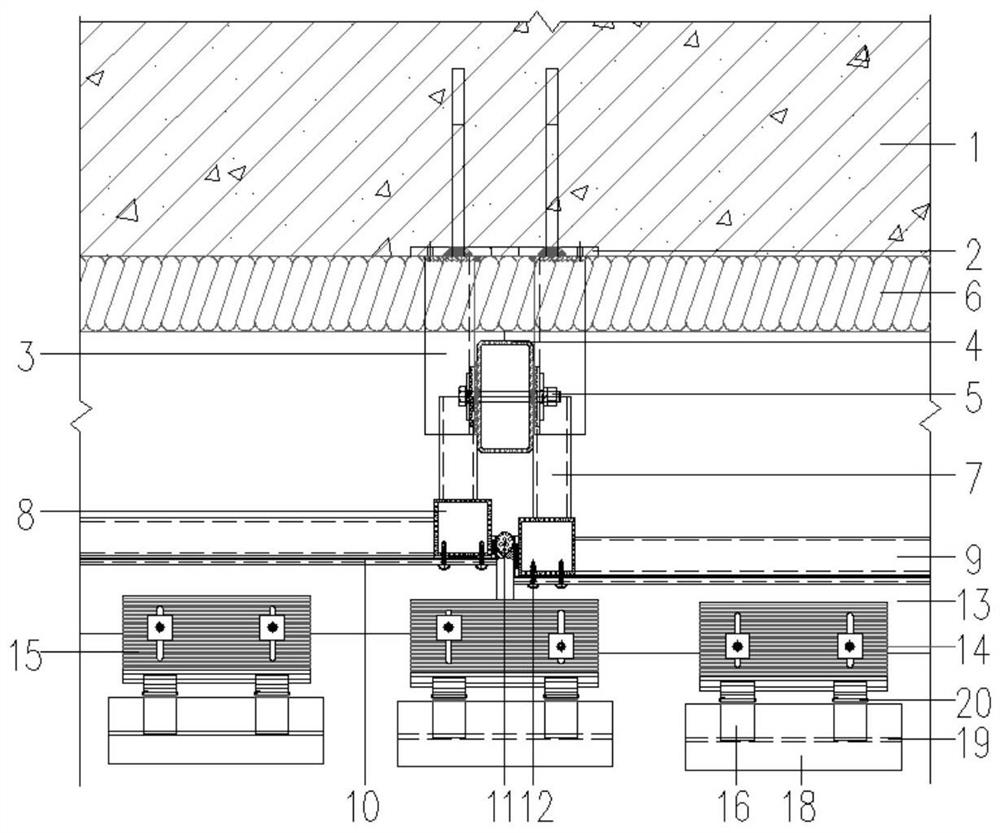

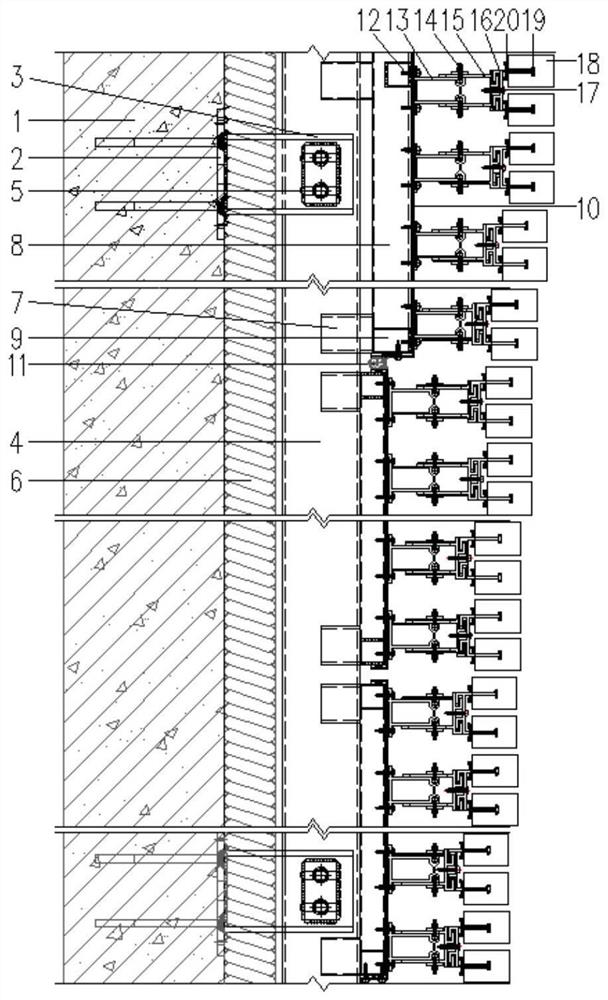

[0056] see Figure 1 to Figure 5 , shows the dry-hanging structure and construction technology of the curved ceramic brick curtain wall of the present invention.

[0057] Such as figure 1 As shown, the dry-hanging structure of the curved ceramic brick curtain wall is arranged on the outer wall 1 of the main structure, and the outer wall 1 of the main structure is provided with a plurality of embedded parts 2. See also figure 2 with image 3 , two channel steel connectors 3 arranged at intervals are welded on the embedded part 2, and a vertically arranged rectangular steel pipe column 4 passes through the middle of the two channel steel connectors 3 and is connected to the channel steel connector through the column bolt assembly 5 3. For fixed connection, rock wool insulation layer 6 is laid on the outer side of main structure exterior wall 1, and a plurality of rectangular steel pipe connectors 7 are welded on the rectangular steel pipe column 4, see also Figure 5 , the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com