A kind of automobile chassis protective agent and preparation method thereof

A technology of automobile chassis and protective agent, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., which can solve the problems of shortening the service life of vehicles and damage to automobile chassis, so as to improve the anti-stone impact performance and anti-rust performance, and improve adhesion , The effect of high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

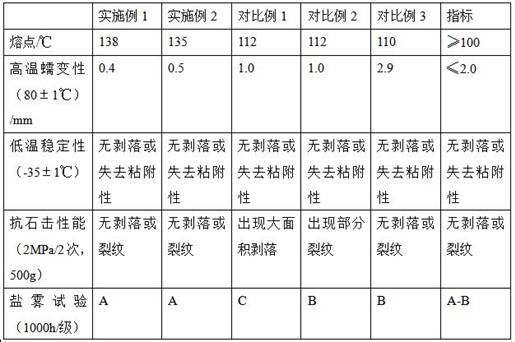

Examples

Embodiment 1

[0018] An automobile chassis protective agent, the parts by weight of the raw materials are: 100 parts of paraffin wax; 30 parts of microcrystalline wax; 4 parts of polyethylene wax; 4 parts of modified montmorillonite; 6 parts of polyurethane acrylate resin; 3 parts of rust inhibitor, 2 parts of calcium salt type rust inhibitor, 3 parts of non-ionic rust inhibitor, 4 parts of phenolic antioxidant, the modified montmorillonite is obtained by using CTAB modified sodium-based montmorillonite wherein the sulfonate type rust inhibitor is sodium petroleum sulfonate, the calcium salt type rust inhibitor is calcium petroleum sulfonate, the nonionic rust inhibitor is sorbitol monooleate, and the phenolic antioxidant is 2, 6-Di-tert-butyl-p-cresol.

[0019] In this embodiment, the preparation method of the modified montmorillonite is as follows: ultrasonically disperse 100 mg of sodium-based montmorillonite in deionized water, adjust the pH value to 11 with sodium carbonate, stir magne...

Embodiment 2

[0022] An automobile chassis protective agent, the parts by weight of the raw materials are: 90 parts of paraffin wax; 28 parts of microcrystalline wax; 3 parts of polyethylene wax; 2 parts of modified montmorillonite; 8 parts of polyurethane acrylate resin; 2 parts of rust inhibitor, 1 part of calcium salt type rust inhibitor, 3 parts of non-ionic rust inhibitor, 3 parts of phenolic antioxidant, the modified montmorillonite is obtained by using CTAB modified sodium-based montmorillonite wherein the sulfonate type rust inhibitor is sodium petroleum sulfonate, the calcium salt type rust inhibitor is calcium petroleum sulfonate, the nonionic rust inhibitor is sorbitol monooleate, and the phenolic antioxidant is 2, 6-Di-tert-butyl-p-cresol.

[0023] In this embodiment, the preparation method of the modified montmorillonite is as follows: ultrasonically disperse 100 mg of sodium-based montmorillonite in deionized water, adjust the pH value to 11 with sodium carbonate, stir magneti...

Embodiment 3

[0026] An automobile chassis protective agent, the parts by weight of the raw materials are: 100 parts of paraffin wax; 20 parts of microcrystalline wax; 6 parts of polyethylene wax; 4 parts of modified montmorillonite; 8 parts of polyurethane acrylate resin; 2 parts of rust inhibitor, 2 parts of calcium salt type rust inhibitor, 2 parts of non-ionic rust inhibitor, 4 parts of phenolic antioxidant, the modified montmorillonite is obtained by using CTAB modified sodium-based montmorillonite wherein the sulfonate type rust inhibitor is sodium petroleum sulfonate, the calcium salt type rust inhibitor is calcium petroleum sulfonate, the nonionic rust inhibitor is sorbitol monooleate, and the phenolic antioxidant is 2, 6-Di-tert-butyl-p-cresol.

[0027] In this embodiment, the preparation method of the modified montmorillonite is as follows: ultrasonically disperse 100 mg of sodium-based montmorillonite in deionized water, adjust the pH value to 11 with sodium carbonate, stir magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com