Color ink-jet printing method based on polystyrene microsphere array structure

A technology of polystyrene microspheres and array structures, which is applied in printing and other directions, and can solve the problems of complex color printing and insufficient printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0025] Such as Figure 1-Figure 6 Shown, based on the color inkjet printing method of polystyrene microsphere array structure, described method comprises:

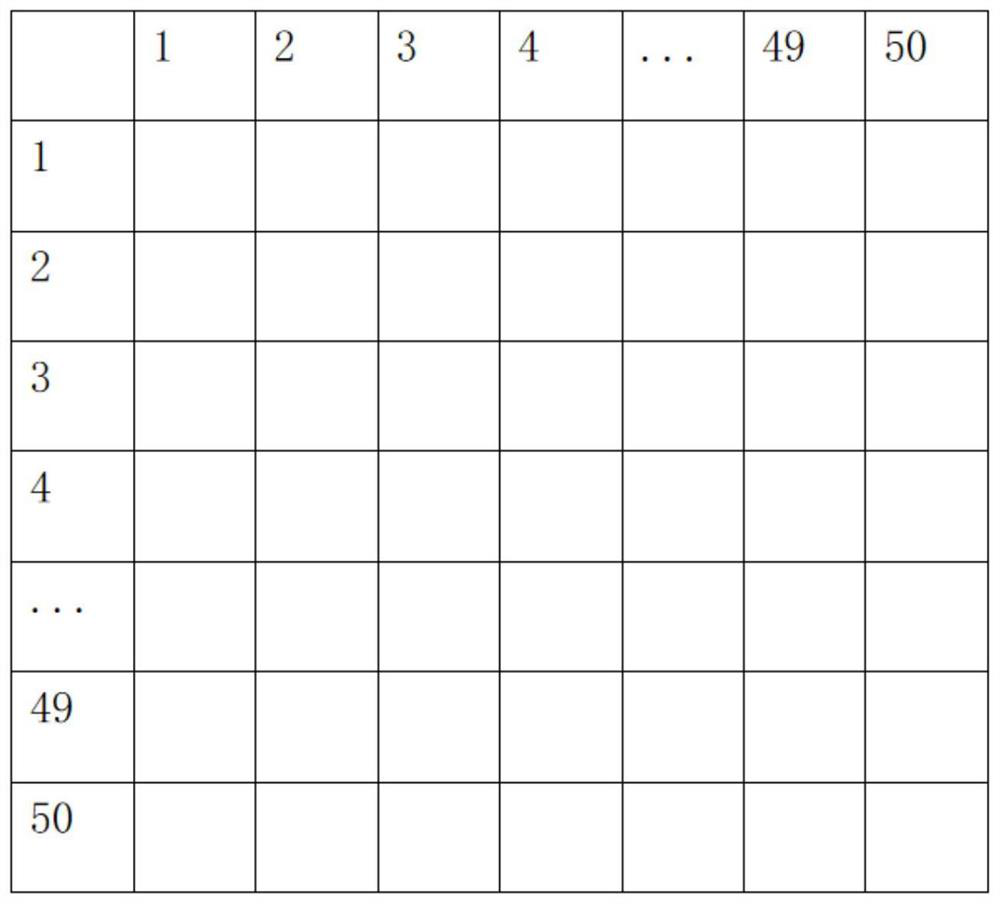

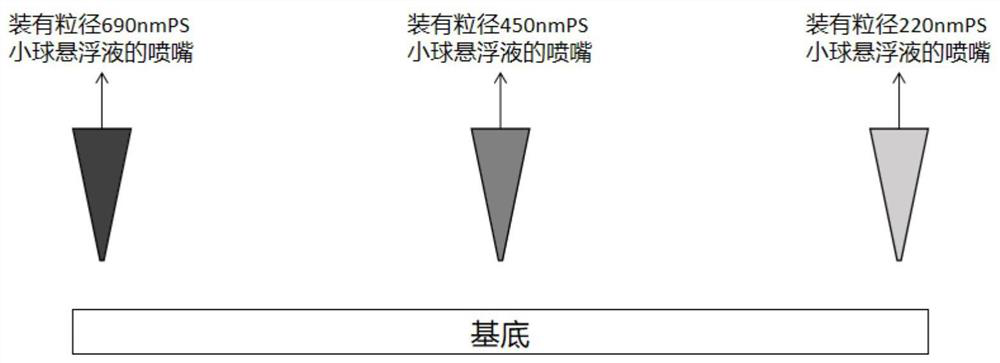

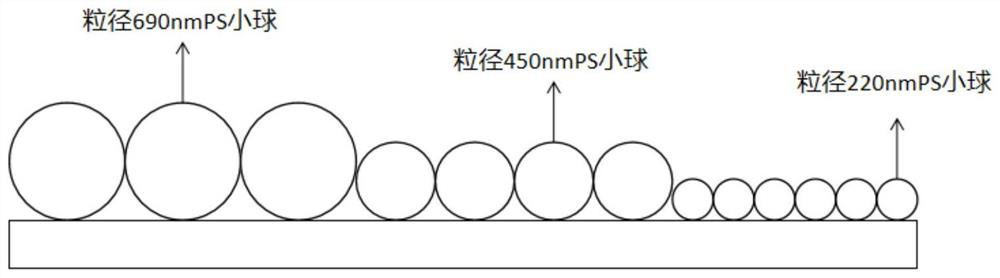

[0026] White PS beads (polystyrene microspheres) powders of different particle sizes are dissolved in absolute ethanol to prepare a variety of suspensions with a certain concentration and containing beads of different particle sizes, and divide different areas on the substrate to be printed According to the color requirements, different suspensions are sprayed to each area through the nozzle; after the solution is spread and evaporated, a film array composed of small balls of different particle sizes can be obtained on the surface of the substrate;

[0027] At this time, another nozzle is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com