Accurately digitized micro-nano imprint method

A micro-nano, precision technology, applied in the field of precision machining, can solve the problems of high manufacturing cost, limited function, inability to make micro-nano structures, etc., and achieve the effects of easy manufacturing, rapid imprinting and replication, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

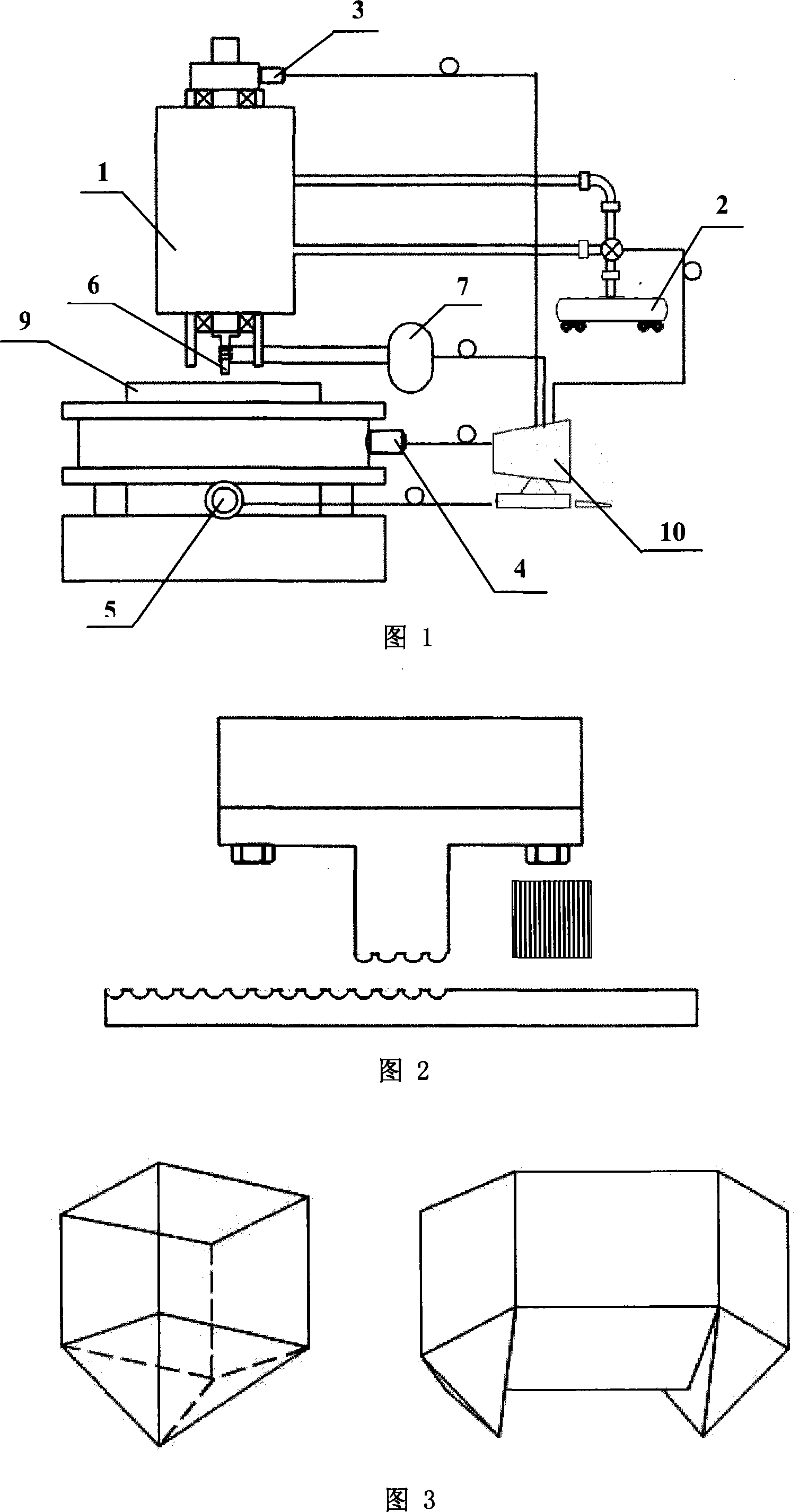

[0052] Embodiment 1: Referring to the accompanying drawing 1, a precision digital micro-nano imprinting device includes a working platform for placing a substrate 9 to be imprinted, an imprinting head 6 for installing an imprinting mold core and its driving device, and a heating and curing structure And the control device, the plane where the substrate 9 to be imprinted is located is the x-y plane, and the working platform is an x-y precision displacement working platform, which is driven by the x-axis servo motor 4 and the y-axis servo motor 5 to realize translation in the x-axis and y-axis directions Movement, the driving device of the embossing die core includes a numerically controlled rotary motion device that rotates the imprinting die core around the z-axis and a vertical translation motion device driven by the z-axis servo motor 3, and the control device provides each motion The control signal of the device, the solidification signal, and realize the pressure control. ...

Embodiment 2

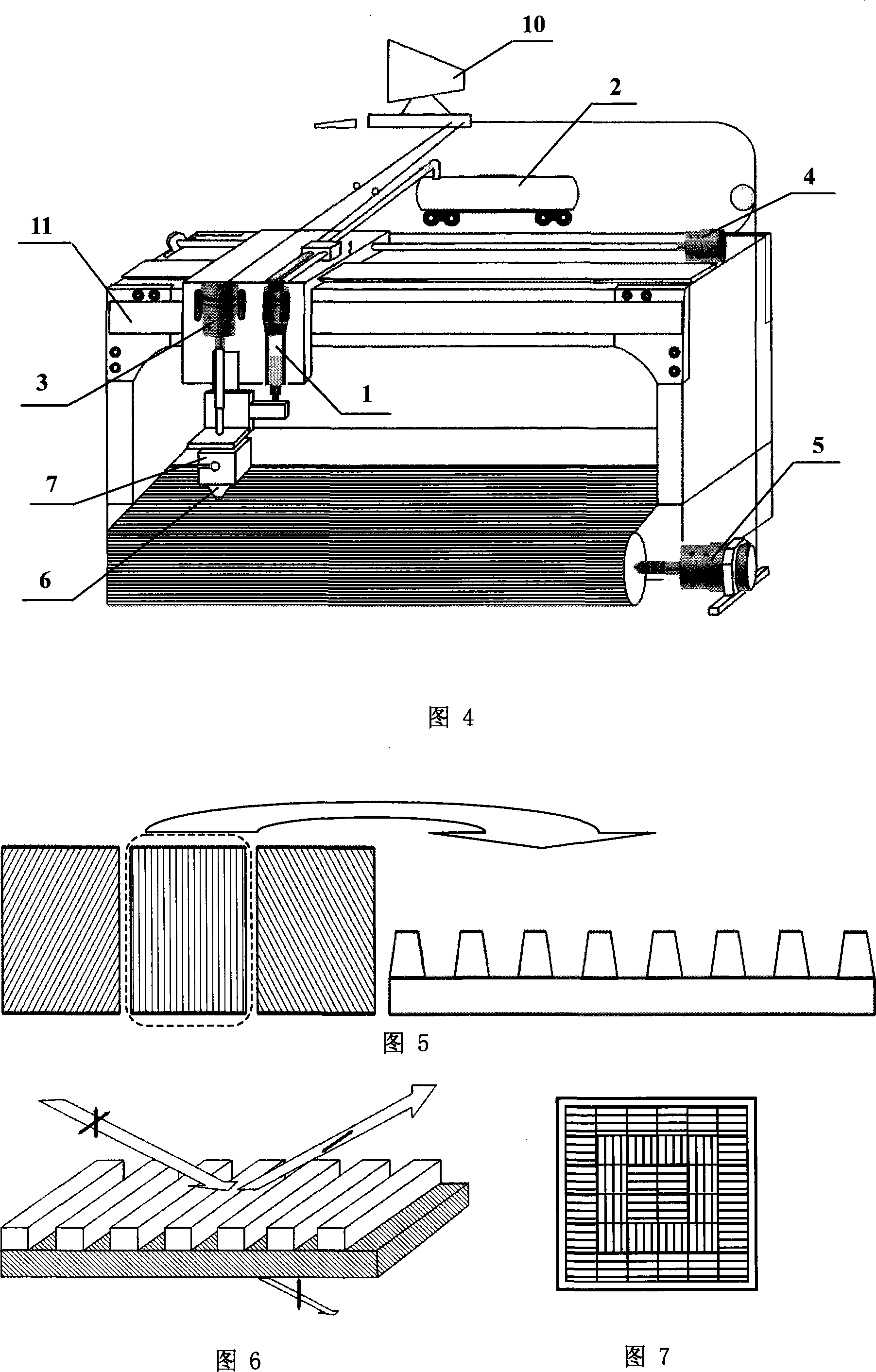

[0068] Embodiment 2: The method of precision digital micro-nano imprinting, its device is shown in accompanying drawing 4, specifically comprises the following steps:

[0069] [1] According to the actual needs, the micro-nano structure of the imprinting core unit is designed, and the finally obtained structure on the substrate is a combination of unit structures with different spatial orientations. Methods for realizing the preset micro-nano structure include ultraviolet lithography, laser direct writing, electron beam, etc. The micro-nano structure can be made directly on high-hardness materials, such as carbon steel, silicon carbide, etc., can also be made on a thin metal nickel plate, and installed on the imprint head 6 of the device.

[0070] [2] Input the spatial orientation functions of micro-nano units with different preset substrate structures into the computer 10 . The movement path of the precision displacement platform in the y direction and the embossing die core ...

Embodiment 3

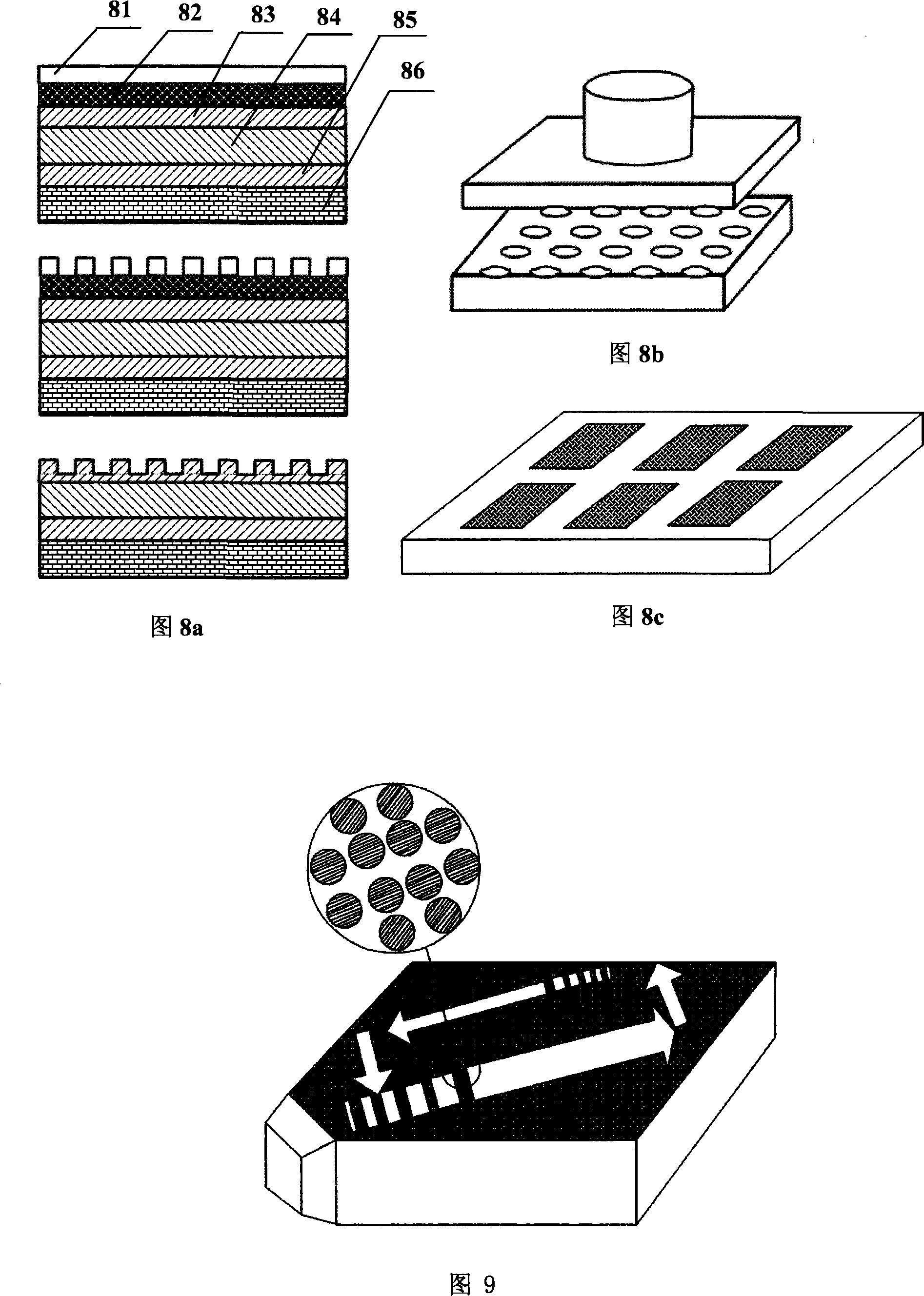

[0075] Embodiment 3: Referring to Figs. 8a-8c, a photonic crystal structure for enhancing the vertical transmission efficiency of a light emitting diode. Figure 8a is a schematic diagram of the fabrication process steps of the structure; each layer structure from top to bottom is heat-sensitive adhesive [81] / chromium mask layer Cr[82] / p-type gallium nitride layer (pGaN)[83] / quantum well Material (QW activelayer)[84] / n-type gallium nitride layer (nGaN)[85] / substrate[86], one of the implementations of the imprinting device implements embossing and primer removal on heat-sensitive materials. After etching the Cr mask [82], etch the pGaN [83] layer to obtain a periodic photonic crystal structure on the light-emitting area. Fig. 8b is a schematic diagram of the embossed structure. Figure 8c is an LED array with the photonic crystal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com