A self-propelled pusher robot

A push robot, self-propelled technology, applied in animal feeding devices, applications, animal husbandry and other directions, can solve the problems of large push resistance, limited driving ability of the push robot, unable to achieve the push effect, etc., to improve the transmission efficiency. and stability, avoid damage to the drive system, avoid the effect of ineffective push material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

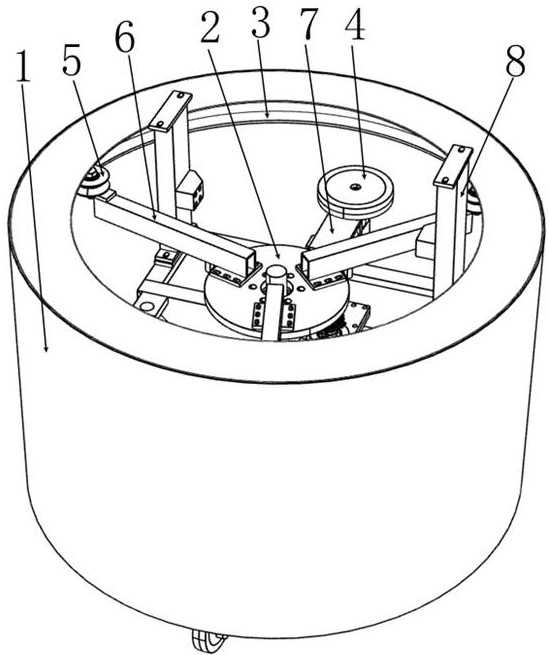

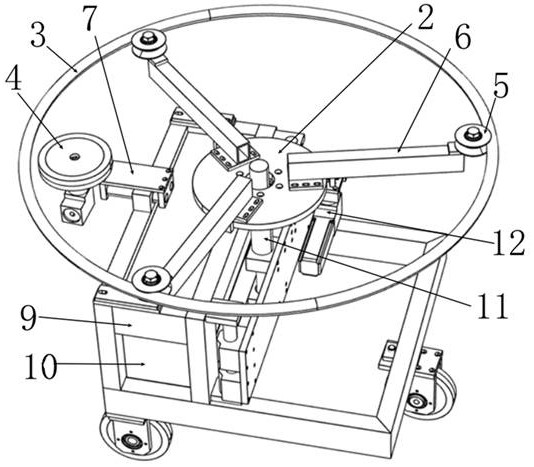

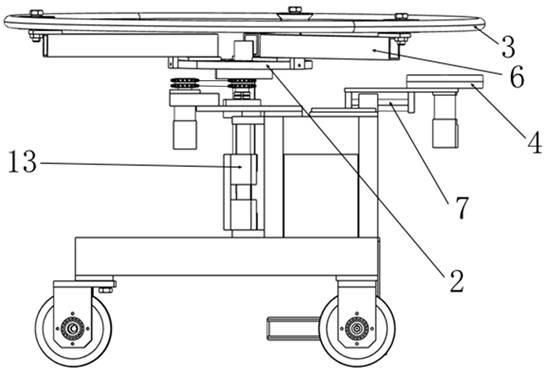

[0029] In a typical embodiment of the present invention, such as Figure 1-Figure 4 As shown, a self-propelled pushing robot is proposed.

[0030] Aiming at the problem that the pushing force of the current pusher robot is insufficient and unable to adapt to the pushing of light feed, which leads to repeated push, a self-propelled pusher robot is provided, which uses the rotary shell 1 as the pusher structure for contacting the feed, and utilizes the rotating shell 1 The active rotation pushes and accumulates the feed, replacing the traditional external friction to drive the rotating shell 1 to rotate, so as to improve the robot's pushing ability and reduce the waste of feed rolling caused by repeated pushing processes.

[0031] For a self-propelled pusher robot, it mainly includes a self-propelled platform, a rotating shell 1, a guide plate 2, a driving wheel 4 and a lifting mechanism. The self-propelled platform, as an overall load-bearing structure, can drive other componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com