Method for modifying organic polymer material and modified organic polymer material

A kind of polymer material and organic technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve difficult and difficult to realize problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

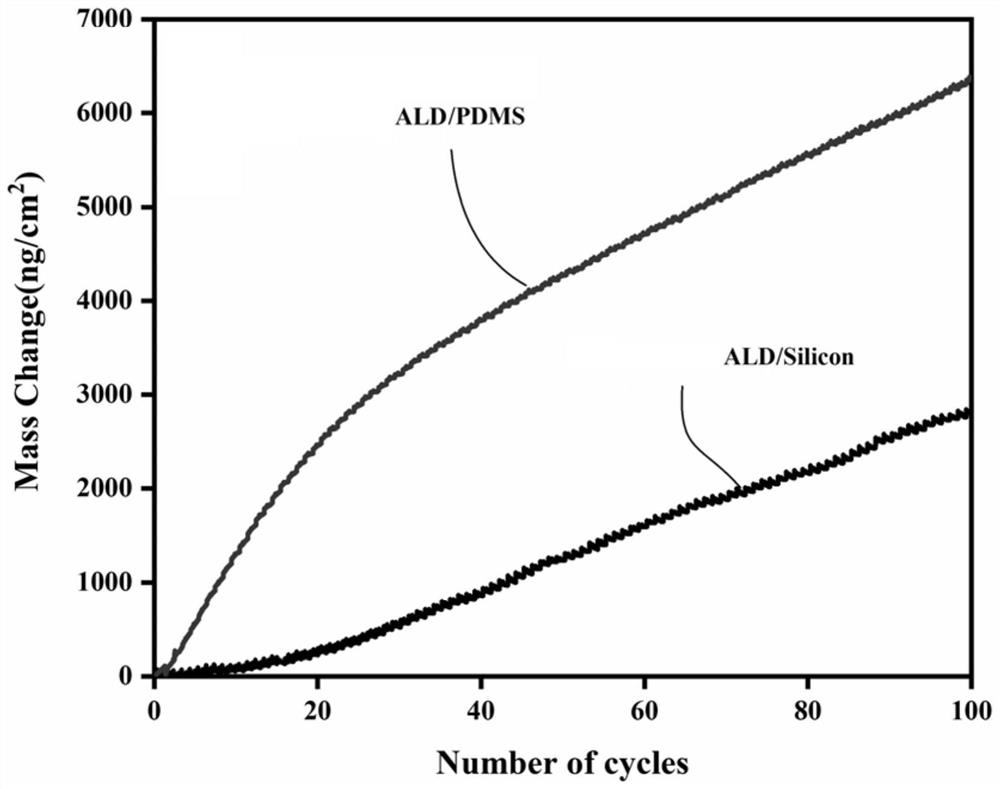

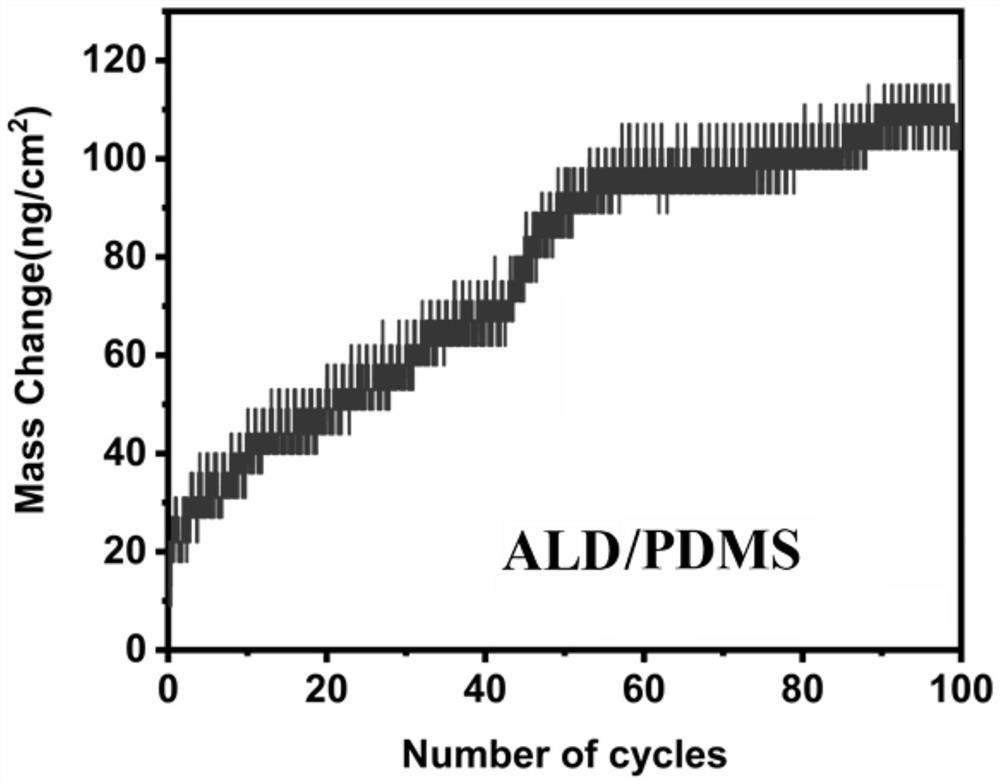

Embodiment 1

[0081] This embodiment provides a method for modifying an organic polymer material and a modified organic polymer material. The specific steps are as follows:

[0082] Step 1: Use acetone, absolute ethanol and deionized water to ultrasonically clean the PDMS (polydimethylsiloxane) polymer membrane for 15 minutes, then dry it with nitrogen, place it in an inert gas environment, and use He plasma to clean it surface.

[0083] Step 2: Use the self-built plasma-enhanced atomic layer deposition equipment, place the cleaned PDMS film with a thickness of 1 micron in the atomic layer deposition reaction chamber of the above equipment, use a vacuum pump to vacuum the atomic layer deposition reaction chamber, and open the carrier. The gas control valve is used to feed 100 sccm carrier gas He into the atomic layer deposition reaction chamber, place trimethylaluminum in the source bottle of the atomic layer deposition equipment, and heat to 28°C.

[0084] Step 3: Control the temperature ...

Embodiment 2

[0092] This embodiment provides a method for modifying an organic polymer material and a modified organic polymer material. The difference from Embodiment 1 lies in that the precursor 1 is different and the process parameters are different. Specific steps are as follows:

[0093] Step 1: Use acetone, absolute ethanol and deionized water to ultrasonically clean the PDMS polymer membrane for 15 minutes, then dry it with nitrogen gas, place it in an inert gas environment, and use He plasma to clean the surface.

[0094] Step 2: Use self-built plasma-enhanced atomic layer deposition equipment, place the cleaned PDMS film in the atomic layer deposition reaction chamber of the above equipment, use a vacuum pump to vacuum the atomic layer deposition reaction chamber, open the carrier gas control valve, 100 sccm of carrier gas He was introduced into the atomic layer deposition reaction chamber, tris(dimethylamino)silane TDMAS was placed in the source bottle of the atomic layer deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com