Vacuum coating equipment for preparing piezoelectric ceramics

A technology for vacuum coating and piezoelectric ceramics, applied in the field of piezoelectric ceramics, can solve the problems of toxic gas pollution, high production cost, poor film quality, etc., and achieve the effects of improving deposition rate, compact structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

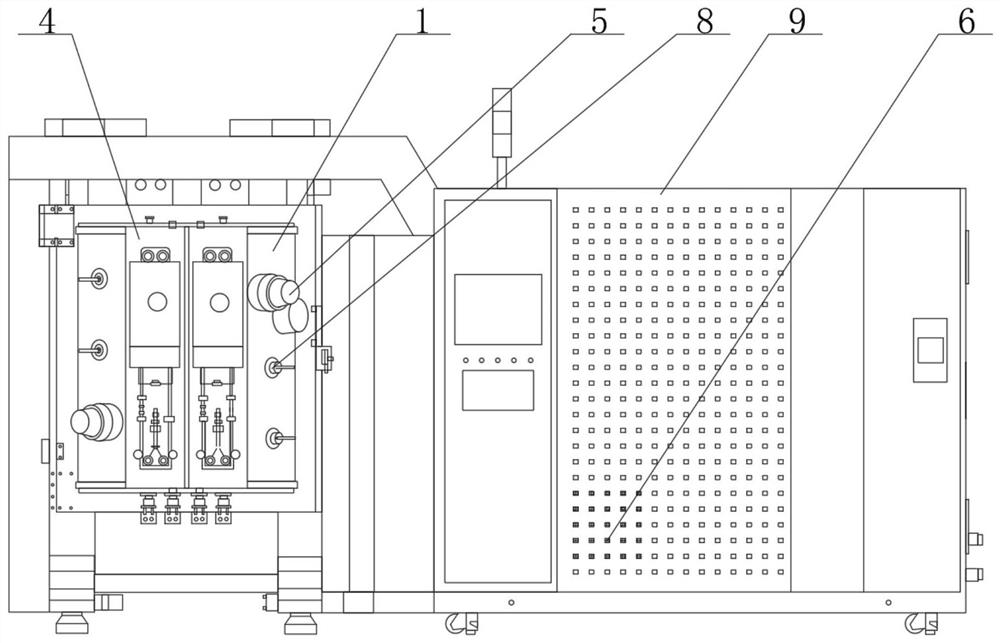

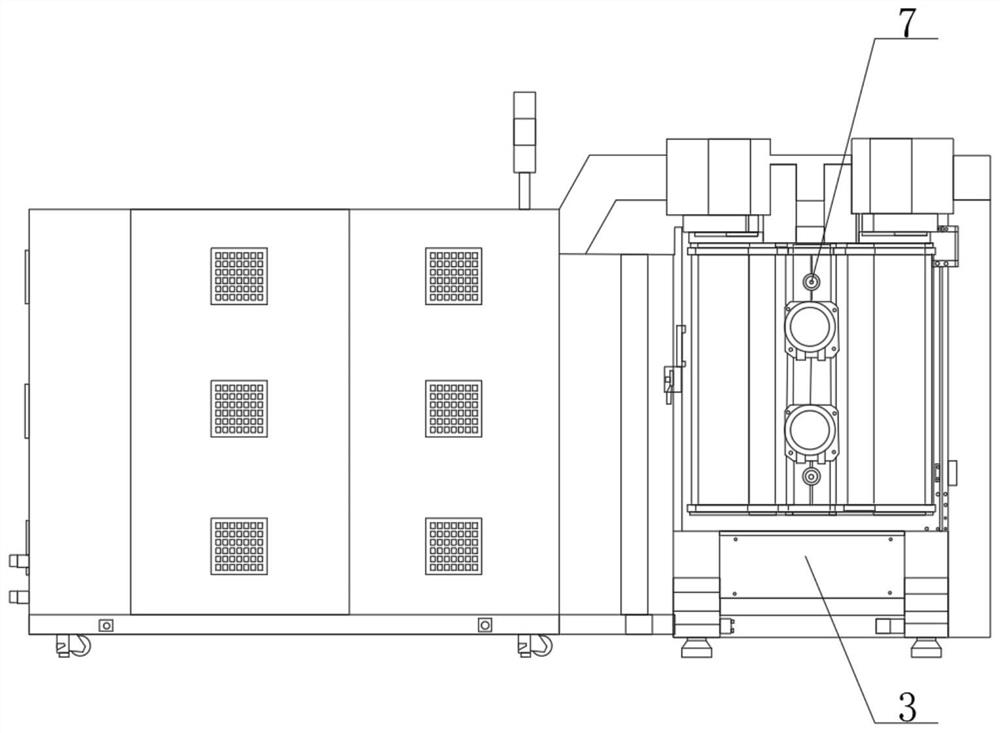

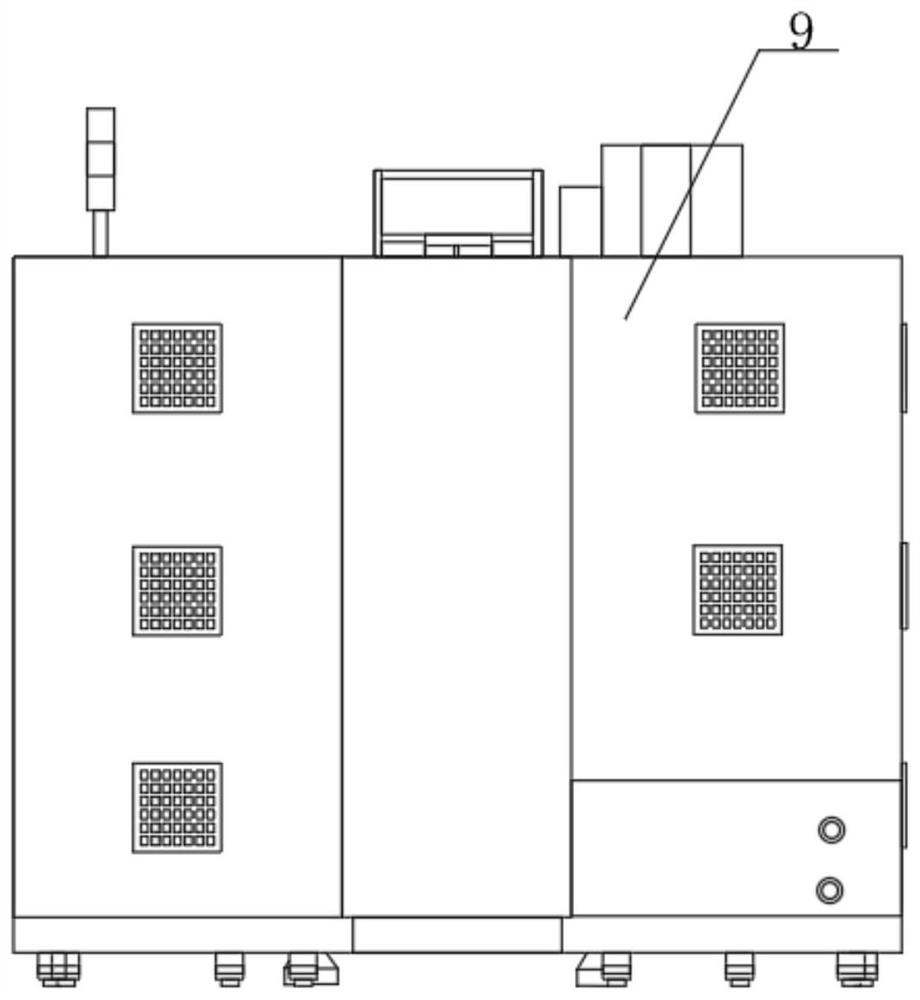

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0026]A vacuum coating device for preparing piezoelectric ceramics, comprising a vacuum coating chamber 1, a vacuum system 2 is fixedly connected to the inside of the vacuum coating chamber 1, and the vacuum system 2 includes a mechanical pump 201, a film gauge 208, a cold cathode gauge 209 and a pneumatic discharge chamber. An air valve 211, a mechanical pump 201 is provided outside the vacuum coating chamber 1, one end of the mechanical pump 201 is connected to a Roots pump 202 through a connecting pipe, and the other end of the Roots pump 202 is connected to a pneumatic vacuum baffle valve 203 through a connecting pipe, The other end of the vacuum flapper valve 203 is connected to a motor-driven throttle valve 210 through a three-way pipe, and the other end of the three-way pipe connected to the pneumatic vacuum flapper valve 203 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com