Recyclable prefabricated runway as well as preparation method and recycling method thereof

A prefabricated, runway technology, applied to chemical instruments and methods, roads, roads, etc., can solve the problems of unrecyclable and difficult to recycle, and achieve high efficiency of on-site paving, safe, non-toxic and environmentally friendly production process, and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] A method for preparing a recyclable prefabricated runway described in any one of the above, comprising the following steps:

[0068] Weighing surface layer raw materials by weight, mixing and granulating to obtain surface layer granules;

[0069] Weighing the bottom layer raw materials by weight, mixing and granulating to obtain the bottom layer particles;

[0070] The surface layer particles and the bottom layer particles are extruded separately under heating conditions to obtain the surface layer and the bottom layer, which are compounded to form a double-layer film;

[0071] The double-layer film is cut, rolled, cooled, trimmed to obtain the finished product.

[0072] The application also provides the preparation method of the above-mentioned recyclable prefabricated runway, which has simple process, low energy consumption, adopts normal pressure thermoplastic processing technology, can be used without vulcanization, can be continuously produced on the assembly line...

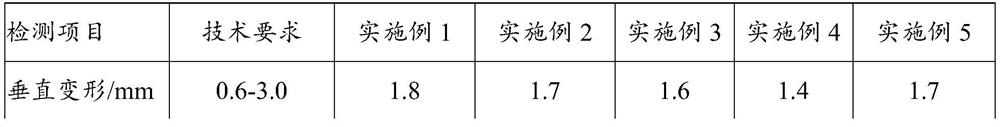

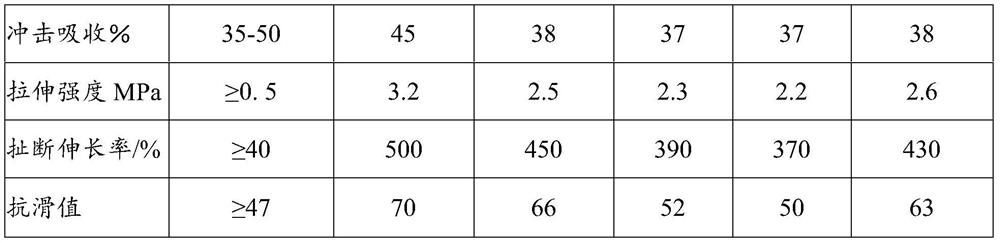

Embodiment 1

[0096] A recyclable prefabricated runway roll, including a prefabricated surface layer and a bottom layer;

[0097] Wherein the surface layer is mainly prepared from the following ingredients in parts by weight:

[0098]50 parts by weight of polyurethane elastomer, 50 parts by weight of SEBSYH-503T, 25 parts by weight of polypropylene, 15 parts by weight of PP-g-MAH, 200 parts by weight of calcium carbonate, 35 parts by weight of emery, 55 parts by weight of white oil, stearin 3 parts by weight of acid, 3 parts by weight of polyethylene wax, 1 part by weight of antioxidant 1010, 2 parts by weight of antioxidant 168, 0.5 part by weight of light stabilizer UV-770DF, 0.5 part by weight of light stabilizer UV-326, oxidation 30 parts by weight of iron red;

[0099] The bottom layer is mainly prepared from the following ingredients in parts by weight:

[0100] 50 parts by weight of polyurethane elastomer, 50 parts by weight of SEBSYH-503T, 25 parts by weight of polypropylene, 15 p...

Embodiment 2

[0110] A recyclable prefabricated runway roll, including a prefabricated surface layer and a bottom layer;

[0111] Wherein the surface layer is mainly prepared from the following ingredients in parts by weight:

[0112] 50 parts by weight of polyurethane elastomer, 50 parts by weight of SEBSYH-503T, 25 parts by weight of polypropylene, 15 parts by weight of PP-g-MAH, 200 parts by weight of calcium carbonate, 20 parts by weight of emery, 55 parts by weight of white oil, stearin 3 parts by weight of acid, 3 parts by weight of polyethylene wax, 1 part by weight of antioxidant 1010, 2 parts by weight of antioxidant 168, 0.5 parts by weight of light stabilizer UV-770DF, 0.5 parts by weight of light stabilizer UV-327, oxidation 30 parts by weight of iron red;

[0113] The bottom layer is mainly prepared from the following ingredients in parts by weight:

[0114] 50 parts by weight of polyurethane elastomer, 50 parts by weight of SEBSYH-503T, 25 parts by weight of polypropylene, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com