Process for synthesizing vinyl chloride by using mercury-free catalyst

A technology of mercury catalyst and vinyl chloride, applied in the field of synthesizing vinyl chloride using mercury-free catalyst, can solve the problem of high water content, and achieve the effects of reducing water content, improving conversion effect, and reducing hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

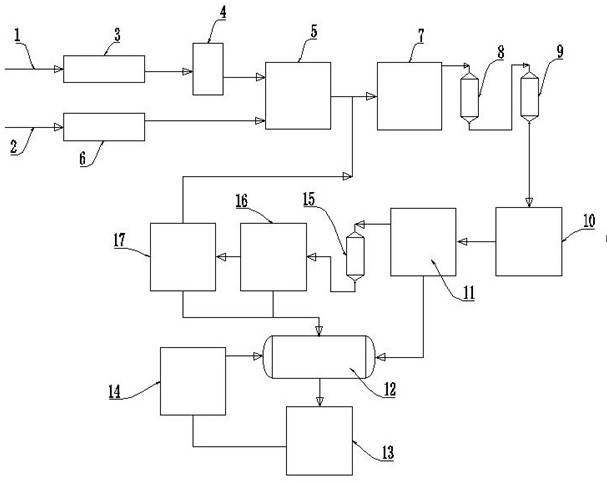

[0041] Such as figure 1 As shown, a system for synthesizing vinyl chloride using a mercury-free catalyst includes: hydrogen chloride gas inlet pipe 1, acetylene gas inlet pipe 2, sulfuric acid drying tower 3, pressure swing adsorption device 4, mixer 5, acetylene drying device 6, pre- Heater 7, mercury-free foreground converter 8, mercury-free background converter 9, corrosion-resistant compressor 10, first condenser 11, crude monomer storage tank 12, rectification system 13, dichloroethane purification and rectification system 14. Mercury-free three-stage converter 15, second condenser 16, and gas-liquid separator 17.

[0042] A process for synthesizing vinyl chloride using a mercury-free catalyst, specifically:

[0043] 1. Raw material dehydration: pass the raw material hydrogen chloride gas into the sulfuric acid drying tower 3 for washing, drying and dehydration to obtain dehydrated dry hydrogen chloride gas;

[0044] The moisture content of the raw material hydrogen chl...

Embodiment 2

[0063] A process for synthesizing vinyl chloride using a mercury-free catalyst, specifically:

[0064] 1. Raw material dehydration: pass the raw material hydrogen chloride gas into the sulfuric acid drying tower 3 for washing, drying and dehydration to obtain dehydrated dry hydrogen chloride gas;

[0065] The moisture content of the raw material hydrogen chloride gas is ≥1000ppm before dehydration, and the moisture content after dehydration is ≤300ppm.

[0066] The sulfuric acid concentration in the described sulfuric acid drying tower 3 is 98%.

[0067] 2. Separation of hydrogen: the dehydrated dry hydrogen chloride gas is passed into the pressure swing adsorption device 4 to separate excess hydrogen from hydrogen chloride to obtain dry hydrogen chloride after hydrogen separation.

[0068] The mass fraction of hydrogen chloride in the dehydrated dry hydrogen chloride gas is 94.3%, and the hydrogen content is 300ppm; the mass fraction of hydrogen chloride in the dry hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com