Elm-shaped molybdenum diselenide@nitrogen-doped carbon nanofibers as well as preparation method and application thereof

A technology of nanofibers and nitrogen-doped carbon, applied in secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problem of low specific capacity, achieve high specific capacity, improve cycle stability, and high activity ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

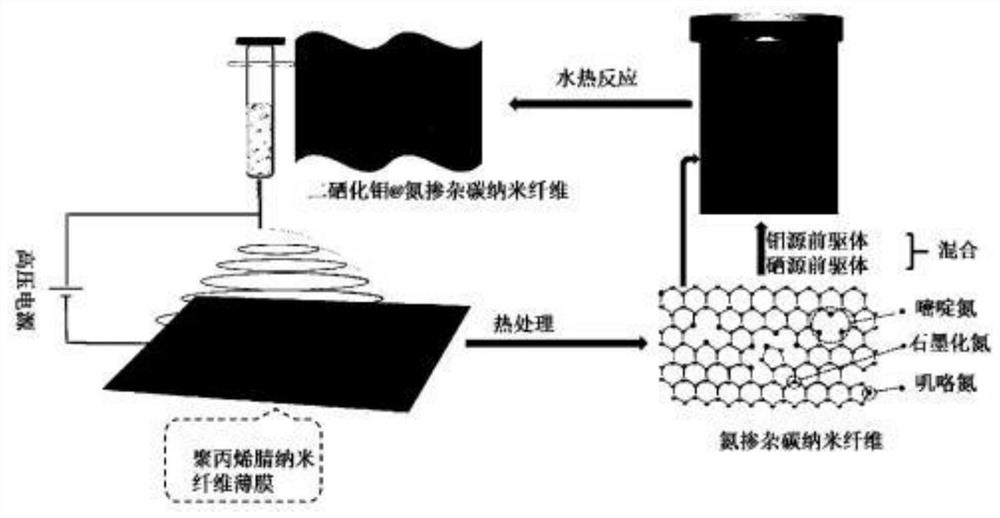

[0032] The invention provides a method for preparing elm-shaped molybdenum diselenide@nitrogen-doped carbon nanofibers, comprising the following steps:

[0033] mixing polyacrylonitrile and N,N-dimethylformamide to obtain a precursor solution;

[0034] Electrospinning the precursor solution to obtain a flexible film;

[0035] heat-treating the flexible film to obtain nitrogen-doped carbon nanofibers;

[0036] Mixing the nitrogen-doped carbon nanofibers, the molybdenum source precursor and the selenium source precursor and performing a hydrothermal reaction to obtain a hydrothermal product;

[0037] The hydrothermal product is heat-treated in nitrogen to obtain the elm-shaped molybdenum diselenide@nitrogen-doped carbon nanofiber.

[0038]The invention mixes polyacrylonitrile and N,N-dimethylformamide to obtain a precursor solution. In the present invention, the mass ratio of the polyacrylonitrile to N,N-dimethylformamide is preferably 0.5-0.8:5-8. In the present invention, ...

Embodiment 1

[0059] Step 1: Sample Preparation

[0060] Preparation of nitrogen-doped carbon nanofibers:

[0061] Dissolve 0.5g of polyacrylonitrile (Mw=130,000~150,000) in 5g of N,N-dimethylformamide solvent, and stir magnetically at 40°C for 10h to form a uniform and transparent solution, which is used as the precursor of nitrogen-doped carbon nanofibers Electrospinning from bulk solution. During the electrospinning process, the specific experimental parameters ranged as follows: the voltage was 18KV, the distance between the needle and the receiving plate was 15cm, the advancing speed was 10μL / min, the temperature was 35°C, and the humidity was 40%. After the electrospinning is completed, the white flexible film is peeled off from the receiving plate and subjected to heat treatment. During the heat treatment, the steps of pre-oxidation stabilization, carbonization and nitrogen doping are completed. First, the electrospun film was pre-oxidized and stabilized for 2 hours in an air atmos...

Embodiment 2

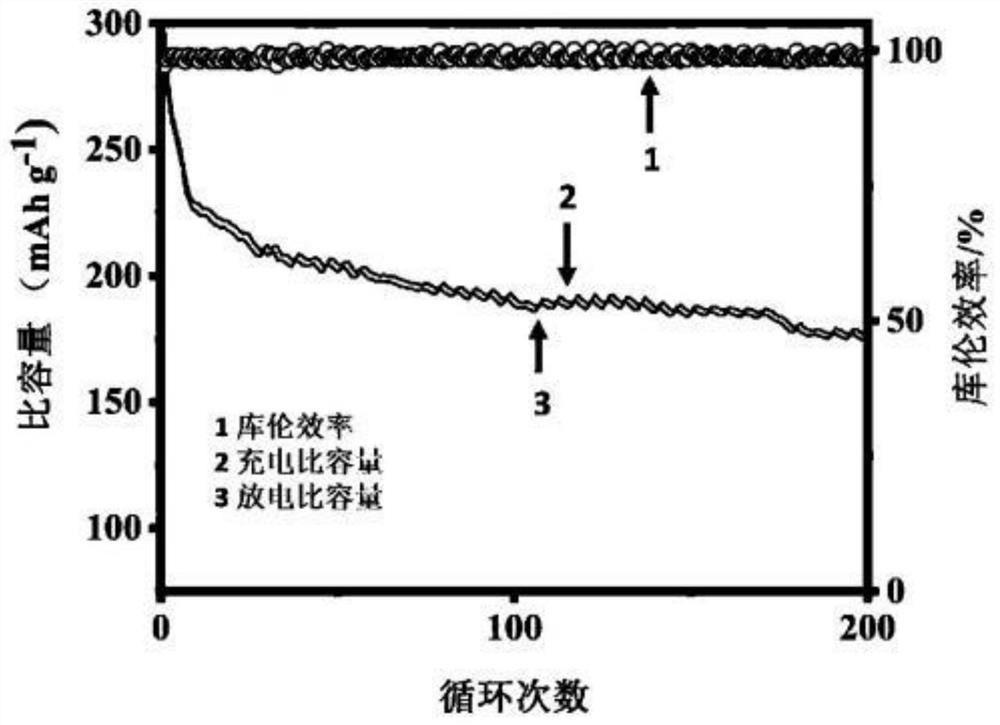

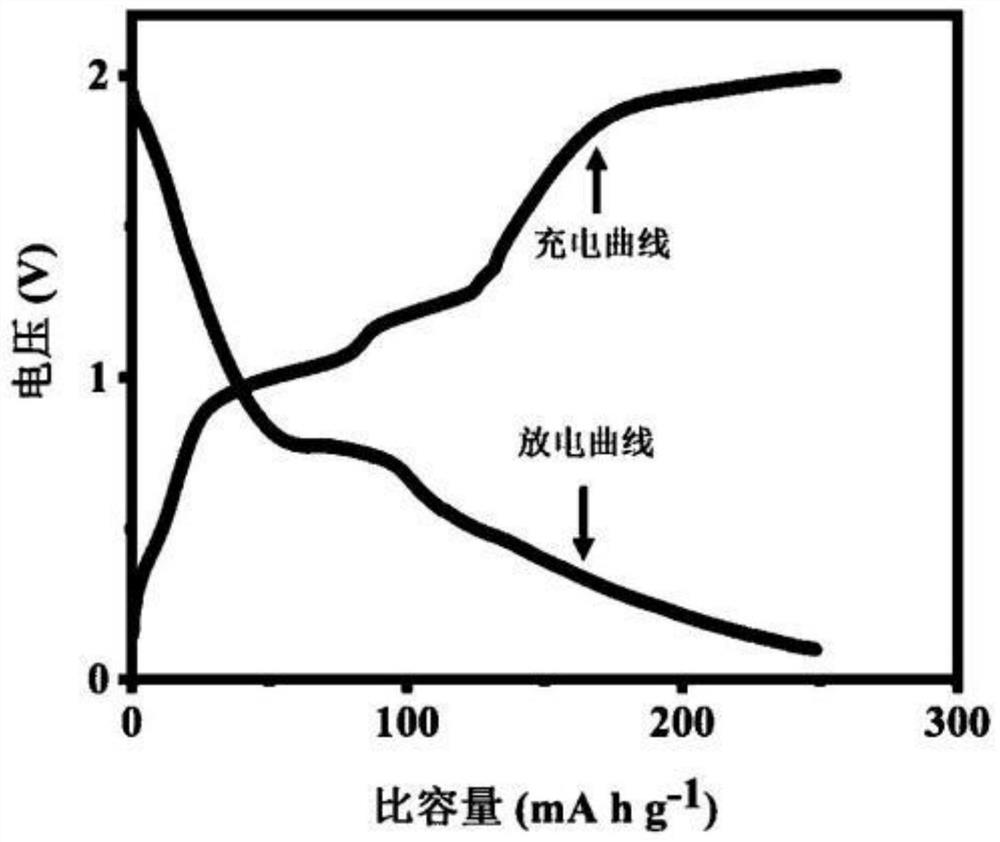

[0087] Step 1: Sample Preparation

[0088] Nitrogen-doped carbon nanofibers were prepared in the same steps as in Example 1 as a molybdenum diselenide hydrothermal growth substrate. Mix 0.05g of nitrogen-doped carbon nanofibers with molybdenum diselenide precursor, wherein the molybdenum diselenide precursor is a mixture of 2mmol sodium molybdate dihydrate dissolved in 50mL deionized water and 4mmol selenium powder dissolved in 10mL hydrazine hydrate solution. Compared with Example 1, the amount of nitrogen-doped carbon nanofiber substrate in Example 2 was halved. During the hydrothermal growth process of molybdenum diselenide, since carbon nanofibers are used as its growth substrate, molybdenum diselenide will be evenly loaded on the carbon substrate, and the amount of substrate will affect the loading effect, thereby affecting the electrochemical performance. In Example 2, the mass fraction of molybdenum diselenide is 91.27%, and the atomic percentage of nitrogen is 2.06%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com