In-situ stretching multi-photon laser confocal imager and method for real-time in-situ three-dimensional observation of internal structure of blended polymer

A laser confocal and polymer blending technology, which is applied in optics, instruments, optical components, etc., can solve problems such as misunderstanding of the true form of two-dimensional image information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

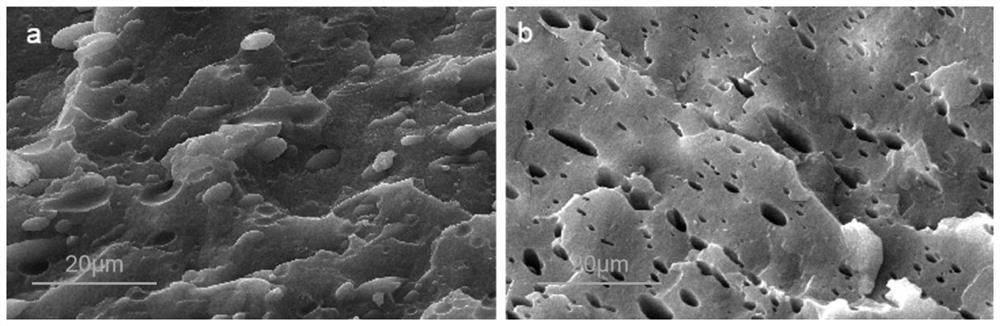

[0059] After mixing 0.8g of polypropylene, 0.2g of polystyrene and 100mL of toluene solvent, add 0.01g of TB under the condition of stirring, drop the obtained mixed solution on the polarizer, and heat at 180°C for 10min to remove the toluene solvent Finally, the temperature was lowered to room temperature at a cooling rate of 1°C / min, 10°C / min and 50°C / min, respectively, to prepare a blended polymer sample containing a fluorescent probe;

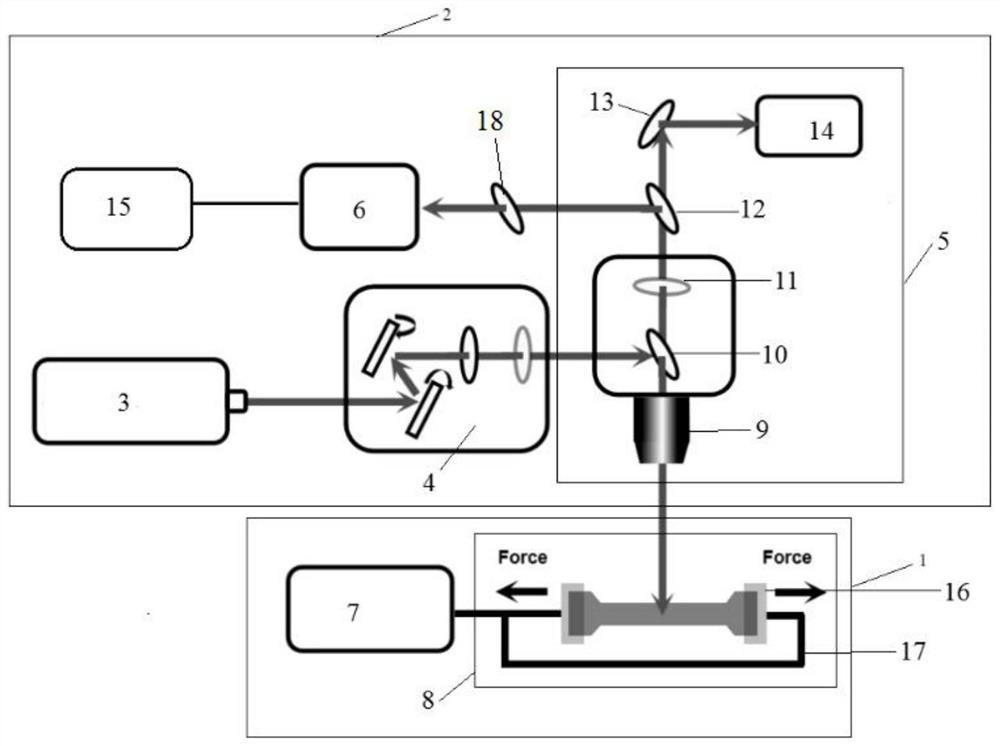

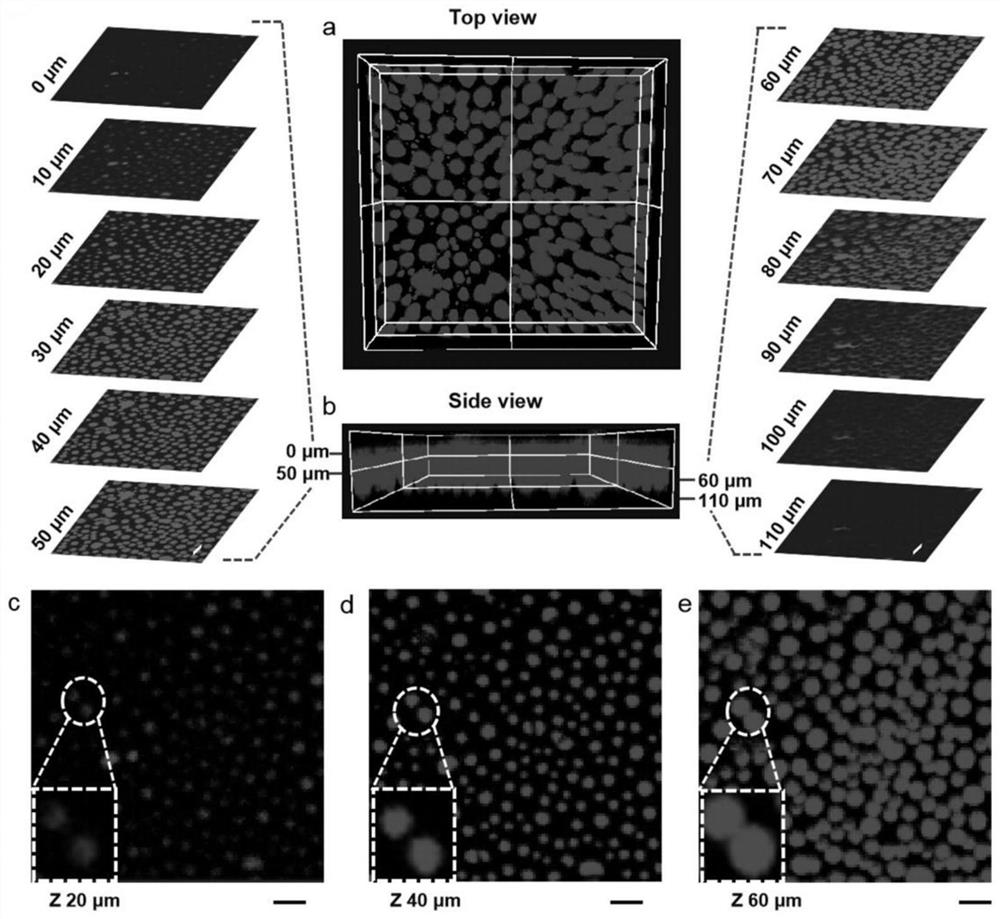

[0060] The blended polymer sample is placed on an adjustable automatic tensile testing machine 1 without stretching, and the femtosecond laser 3 emits a laser with a wavelength of 800 nm, which passes through the scanning part 4 in sequence and is under the control of the software. The objective lens of the optical microscope 5 is moved down along the direction perpendicular to the blended polymer, so that the laser light emitted by the femtosecond laser 3 is focused on the surface of the blended polymer sample 50 away from the fluorescent p...

Embodiment 2

[0067] After mixing 0.8g polypropylene, 0.2g polystyrene and 0.01g TB, blending (blending temperature is 180°C and time is 10min), granulation and injection (temperature is 180°C) in sequence to prepare A 6cm long, 1cm wide, and 0.5cm thick dumbbell-shaped polymer blend sample containing a fluorescent probe;

[0068] The blended polymer sample containing the fluorescent probe is placed on the adjustable automatic tensile testing machine 1, the tensile speed of the adjustable automatic tensile testing machine is set to be 15mm / min, and the femtosecond laser 3 A laser with a wavelength of 800nm is emitted, which passes through the scanning part 4 in sequence and the objective lens of the optical microscope 5 is moved down along the direction perpendicular to the blended polymer under the control of the software, so that the laser emitted by the femtosecond laser 3 Focusing on the surface of the blended polymer sample containing fluorescent probes below 50 micrometers, using Z-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com