Method for measuring penetration depth of permeable liquid hardening agent in cement-based material

A technology of cement-based materials and measurement methods, which is applied in the analysis of suspensions and porous materials, measurement devices, and analysis materials, and can solve problems such as testing penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

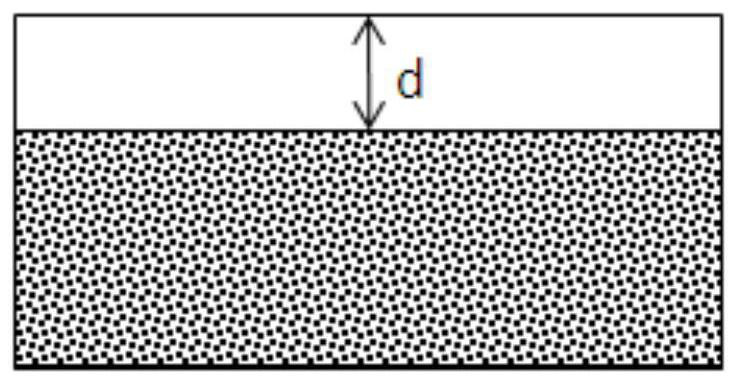

[0048] A commercially available hardener was applied to one surface of a cement-based material sample block for penetrating hardening. Then, along the direction perpendicular to the hardened surface, use a hammer to break the sample apart to obtain a section that is basically perpendicular to the hardened surface. A phenolphthalein indicator is added dropwise on the section to make it develop color, and the result of color development is shown in the appendix Figure 4 shown; attached Image 6 Is a photochromic photograph of an unhardened cement-based material sample (for comparison only).

[0049] Select 7 test points in the middle area with uniform penetration depth at the edge of the color development area, and the distance between each test point is about 10mm; measure the penetration depth of each test point, the results are as follows: 3.3mm, 3.6mm, 4.0mm , 3.7mm, 3.1mm, 3.0mm, 2.9mm.

[0050] The calculated arithmetic average penetration depth of the above 7 test poi...

Embodiment 2

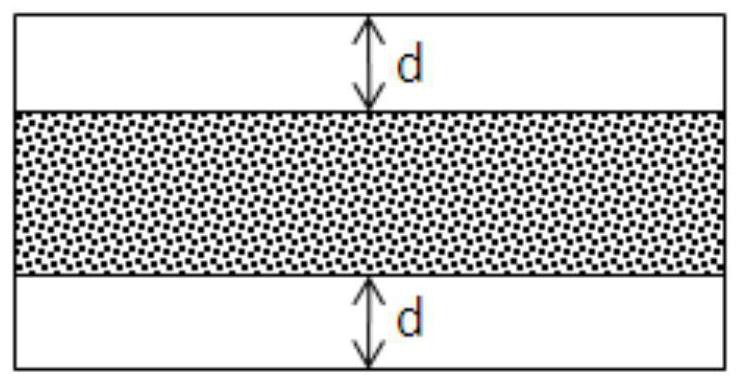

[0052] Apply a commercially available hardener to the two opposite surfaces of the cement-based material sample block for infiltration hardening. Then, along the direction perpendicular to the hardened surface, use a hammer to break the sample apart to obtain a section that is basically perpendicular to the hardened surface. A phenolphthalein indicator is added dropwise on the section to make it develop color, and the result of color development is shown in the appendix Figure 5 shown; attached Image 6 Is a photochromic photograph of an unhardened cement-based material sample (for comparison only).

[0053] Select 10 test points in the middle area with uniform penetration depth at the edge of the color development area, select 5 test points on each side, and the distance between each test point is about 10mm; measure the penetration depth of each test point, and the results are as follows: 3.5mm, 2.8mm, 3.1mm, 3.4mm, 3.9mm, 4.1mm, 4.7mm, 4.5mm, 4.6mm, 4.4mm.

[0054] Calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com