Electromagnetic valve with anti-interference function

A solenoid valve and anti-interference technology, which is applied in the field of solenoid valves, can solve problems such as device leakage, internal valve structure wear, and device influence on normal use of the device, achieving the effect of improving stability and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

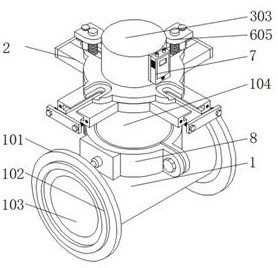

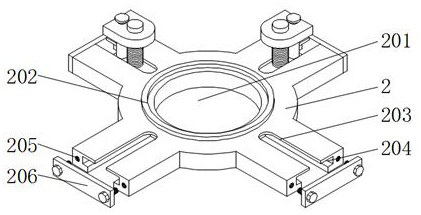

[0037] Embodiment 1: including the valve body 1 and the connecting plate 2, the top of the valve body 1 is installed with a tee pipe 104, the front and back of the valve body 1 are installed with a mounting plate 101, and the front of the mounting plate 101 is equipped with a sealing ring 102 , the inner side of the mounting plate 101 is provided with a water outlet 103, and the inside of the valve body 1 is equipped with an inclined surface 105. The valve body 1 is the main bearing structure of the device, which can provide an installation position for the device on the top, and at the same time can ensure the overall safety of the device. Stability, the tee pipe 104 can provide the installation position for the electromagnetic valve device on the top, to ensure the normal use of the electromagnetic valve device on the top, the installation plate 101 can be connected with the external pipeline, to ensure that the device can be installed and used normally, and the sealing ring 1...

Embodiment 2

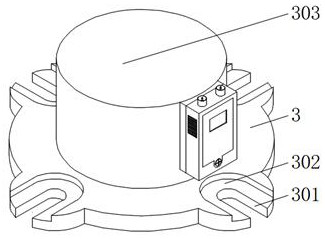

[0039] Embodiment 2: Comprising a combination disk 3, a mounting plate 701 is installed on one side of the combination disk 3, an anti-jamming device 7 is installed on one side of the mounting plate 701, and an anti-jamming device 7 is installed on one side of the mounting plate 701. The front of the jammer 7 is provided with a cooling port 702, the top of the anti-jammer 7 is installed with two sets of data interfaces 703, one side of the anti-jammer 7 is movably installed with a front cover 704, and one side of the front cover 704 is embedded with an observation port 705, one side of the front cover 704 is penetrated with screws 706, and the mounting plate 701 can directly install the anti-jamming device 7 on one side of the top shell 303 to ensure the stability of the anti-jamming device 7, and the anti-jamming device 7 can effectively Provide electromagnetic anti-interference for the inside of the device, and prevent the device from being uncontrollable due to electromagnet...

Embodiment 3

[0041] Embodiment 3: including a three-way pipe 104, a flow frame 503 is installed on the inner side of the three-way pipe 104, a movable valve 5 is installed on the inner side of the flow frame 503, and a transmission rod 501 is installed on the bottom of the movable valve 5, and the transmission rod 501 The bottom of the flow frame 503 is provided with a secondary valve 502, the outer surface of the flow frame 503 is provided with a flow hole 504, the outside of the bottom of the flow frame 503 is provided with a drain hole 505, the outside of the flow frame 503 is provided with a water inlet 506, and the flow frame 503 can be used for The inner solenoid valve device provides the installation position and can provide restriction for the internal water flow to ensure the normal use of the device. The movable valve 5 can be lifted and lowered by the control of the top electromagnetic device to ensure that the device can normally control the switch. The transmission rod 501 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com