Fully-assembled corridor and mounting method thereof

A fully assembled and connected corridor technology, applied in the direction of truss structures, girders, joists, etc., can solve the problems of not being suitable for long-distance construction, etc., and achieve the effect of less cast-in-place operations, less impact on site construction, and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0040] For the convenience of description, the relative positional relationship of each component, such as: the description of up, down, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

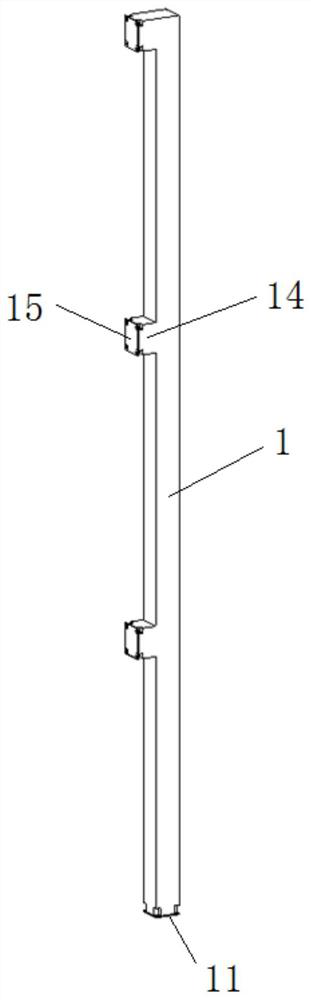

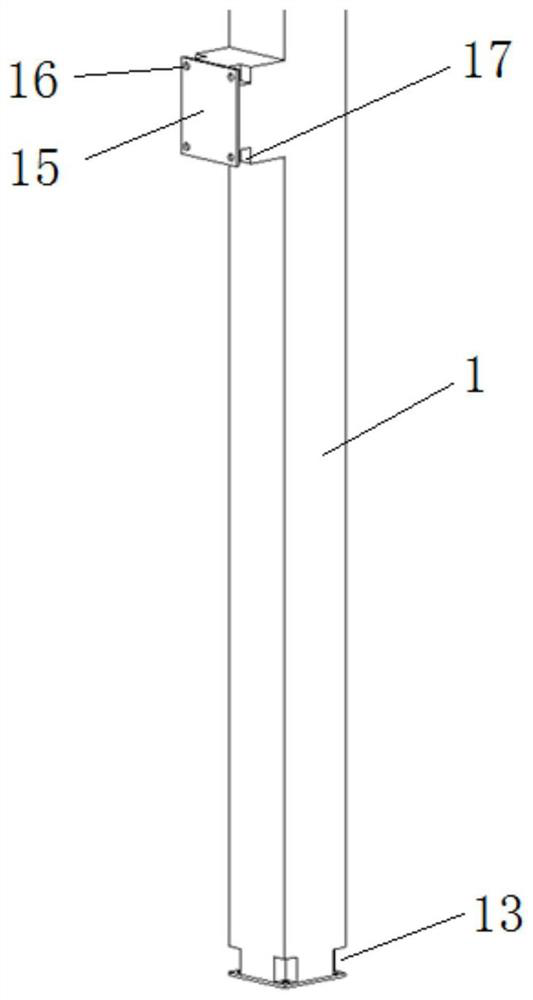

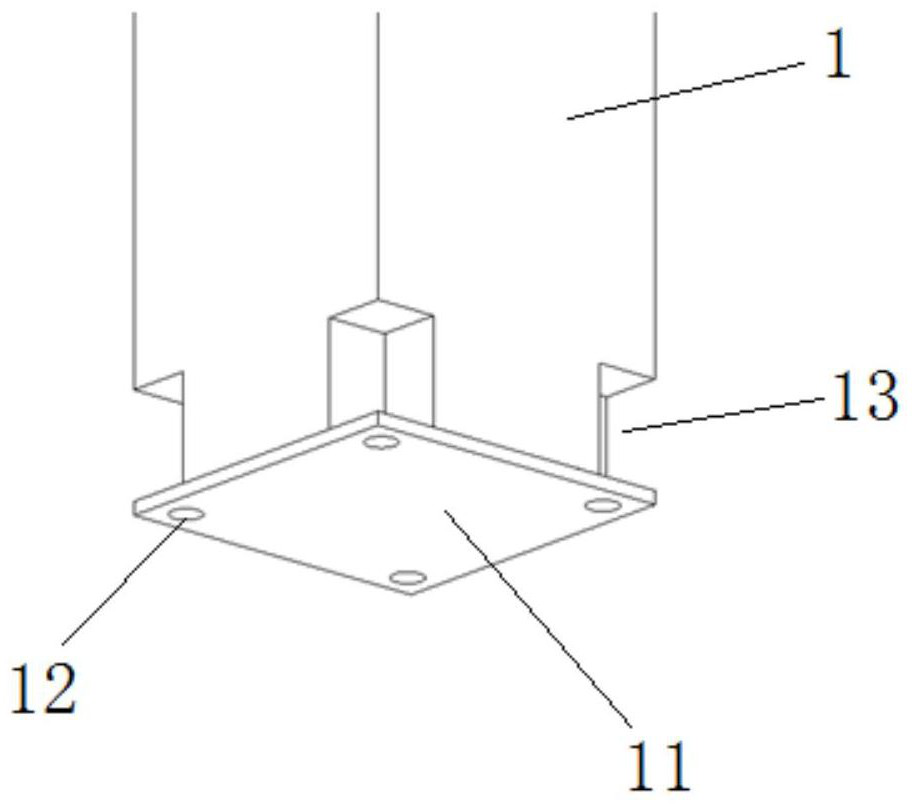

[0041] Such as Figure 17 As shown, an embodiment of the fully assembled corridor of the present invention includes a plurality of prefabricated columns 1, a plurality of prefabricated beams 2, a plurality of prefabricated floors 3, a plurality of prefabricated roofs 4 and a plurality of prefabricated cover plates 5, each prefabricated column 1 two Two groups are arranged equidistantly along the length direction of the corridor. Each group of prefabricated columns is connected by prefabricated beams 2. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com