Metal electrolysis equipment and anode structure

A metal electrolysis and anode structure technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of unstable current, affecting the efficiency of electrolysis, and easy to generate fluctuations, so as to improve the service life, ensure the efficiency of electrolysis, and prevent oxidation and corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

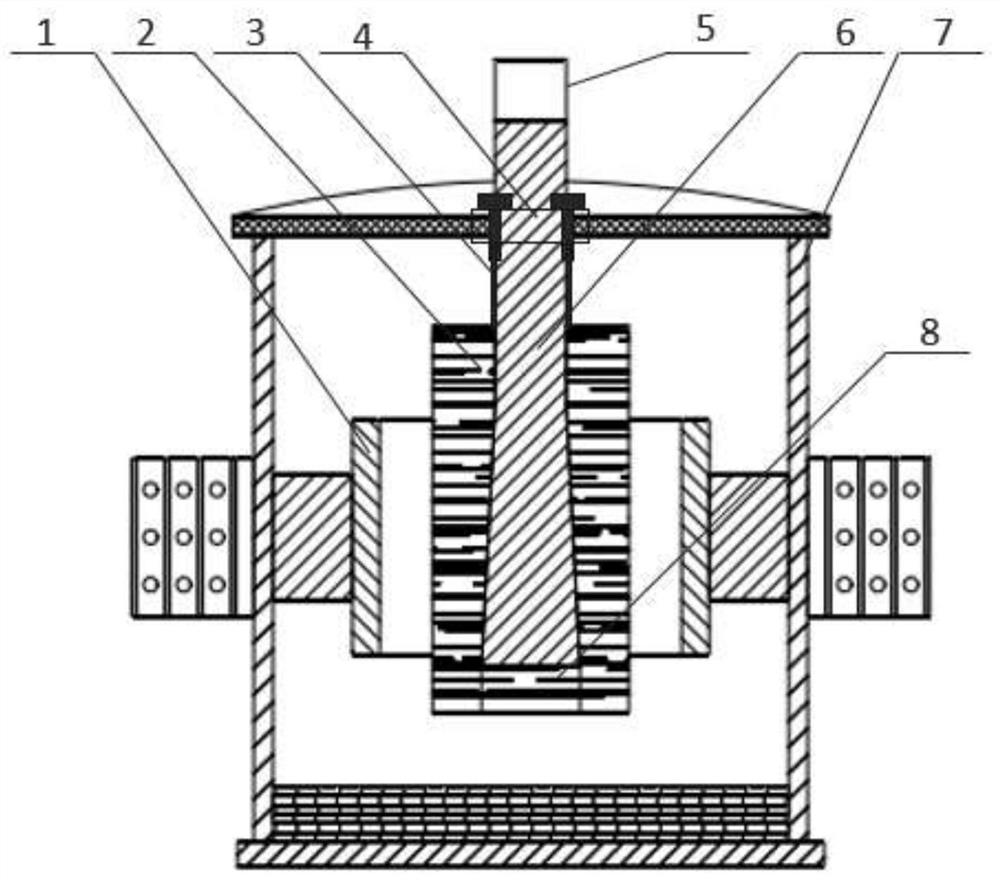

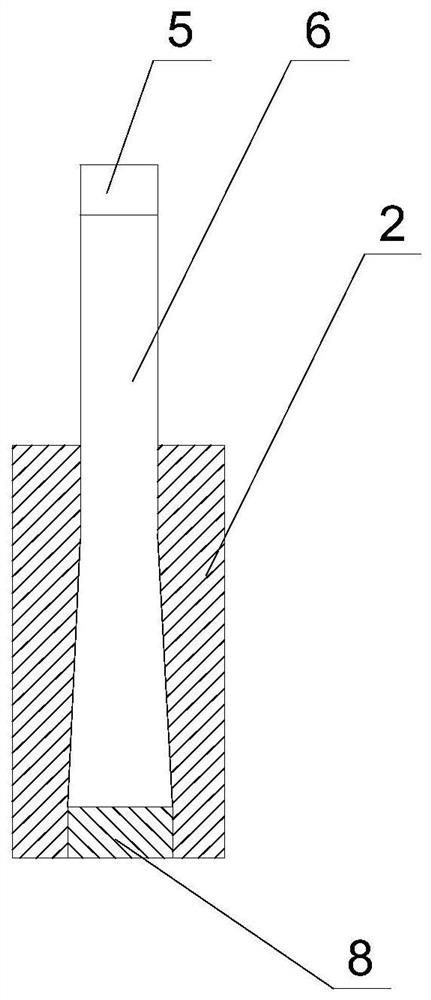

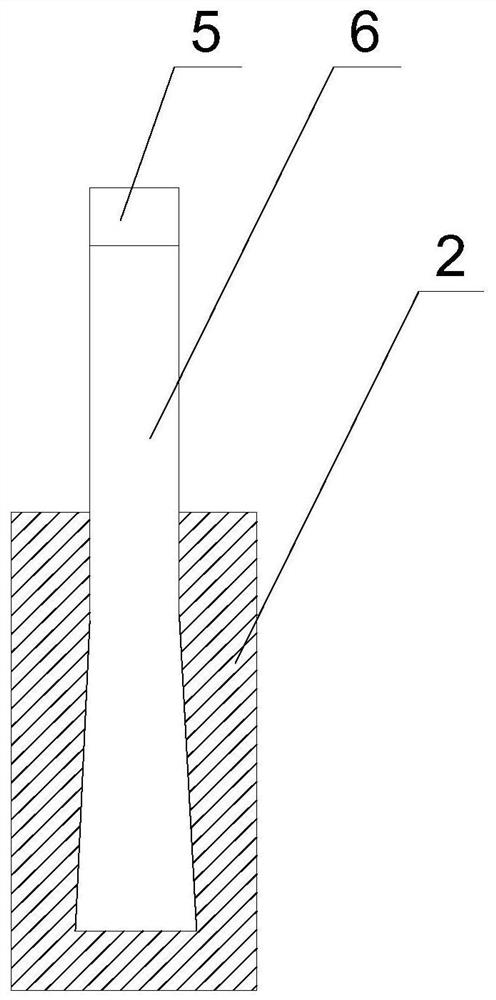

[0026] Such as figure 1 As shown, the metal electrolysis equipment of the present invention includes an electrolytic cell 7 and an anode structure, the electrolytic cell 7 is provided with a cathode 1, the anode structure includes an anode 2 and an anode tab 6, and the anode 2 is located in the electrolytic cell 7 It is inside and sleeved on the outer wall of the anode tab 6 , and one end of the anode tab 6 passes through the electrolytic cell 7 and is located outside the electrolytic cell 7 .

[0027] Electrolyzer 7 comprises tank body and tank cover, is existing conventional structure. The cathode 1 is used to cooperate with the anode 2 to complete the electrolysis reaction. The anode 2 is made of graphite anode. By placing the anode 2 completely inside the electrolytic cell 7 and not in contact with the outside air, it can effectively prevent the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com