Aortic valve composite implant valve system and using method

A technology for aorta and valves, applied in the direction of heart valves, valve rings, balloon catheters, etc., can solve the problem of unstable valve stent fixation, and achieve the effect of reducing the risk of falling off, firm fixation effect, and equal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

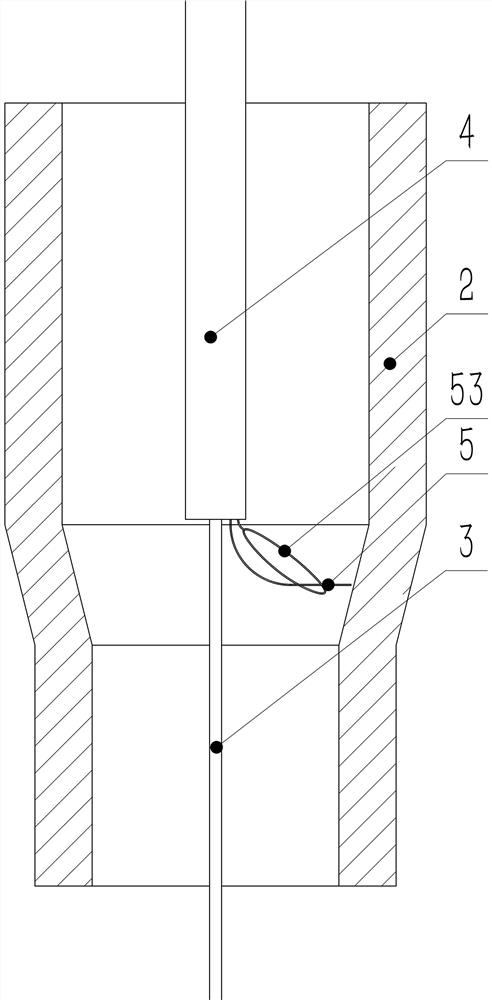

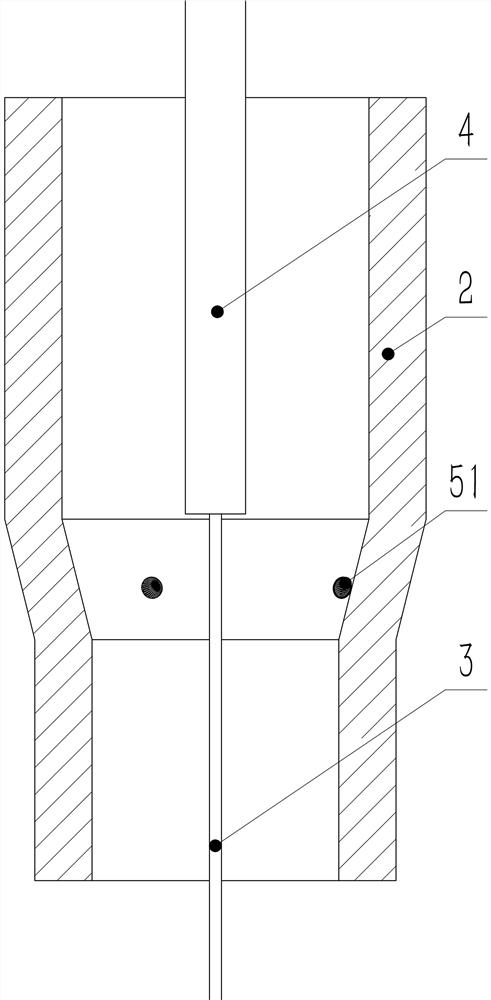

[0037] The following is a detailed explanation of the present invention in conjunction with the specific drawings, such as figure 1 As shown, the valve stent 1 used in this embodiment is roughly the same as the current common stent design, and is divided into upper and lower ends. The diameter of the lower stent 13 is smaller than that of the upper stent 11, but the difference from the existing stent is that, The valve stent 1 designed in this embodiment is provided with a connecting fixed section 12 between the upper stent 11 and the lower stent 13.

[0038] like figure 1 As shown, the diameter of the fixation segment 12 is smaller than the diameter of the lower segment support 13, and is the thinnest among the three parts of the valve support 1. Specifically, the radius of the fixation segment 12 is smaller than that of the lower segment support 13 by 1 to 2 mm; The diameter of the fixing segment 12 is smaller than the diameter of the upper and lower parts, so the valve ste...

Embodiment 2

[0045] This embodiment is not substantially different from the technical solutions used in the above-mentioned embodiments, and the main difference is that: this embodiment is an alternative solution when the patient's native valve does not have a memory material fixing nail 51, and a sclerosing agent is used instead of the memory material. Material for fixing nails.

[0046] like Image 6 As shown, after completing the setting of the guide wire 3 and the catheter 4 according to the method of the above embodiment, the sclerosing agent catheter 9 is inserted into the aortic sinus of the patient along the catheter 4; the sclerosing agent catheter 9 can send the sclerosing agent from the nozzle. , and the hardener is filled in such as Figure 5 The appropriate fixation point 52 in the middle; the sclerosing agent will be adsorbed on the valve, and will harden rapidly after contacting body temperature, forming a firm sclerosing agent fixing nail 91, such as Figure 7 shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com