Steel pile hoisting system for cutter suction dredger

A cutter suction dredger and hoisting system technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve problems such as affecting the efficiency and quality of ship construction, complex structure of steel pile hoisting system, poor ship maneuverability, etc. To achieve the effect of firm fixation, small footprint, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

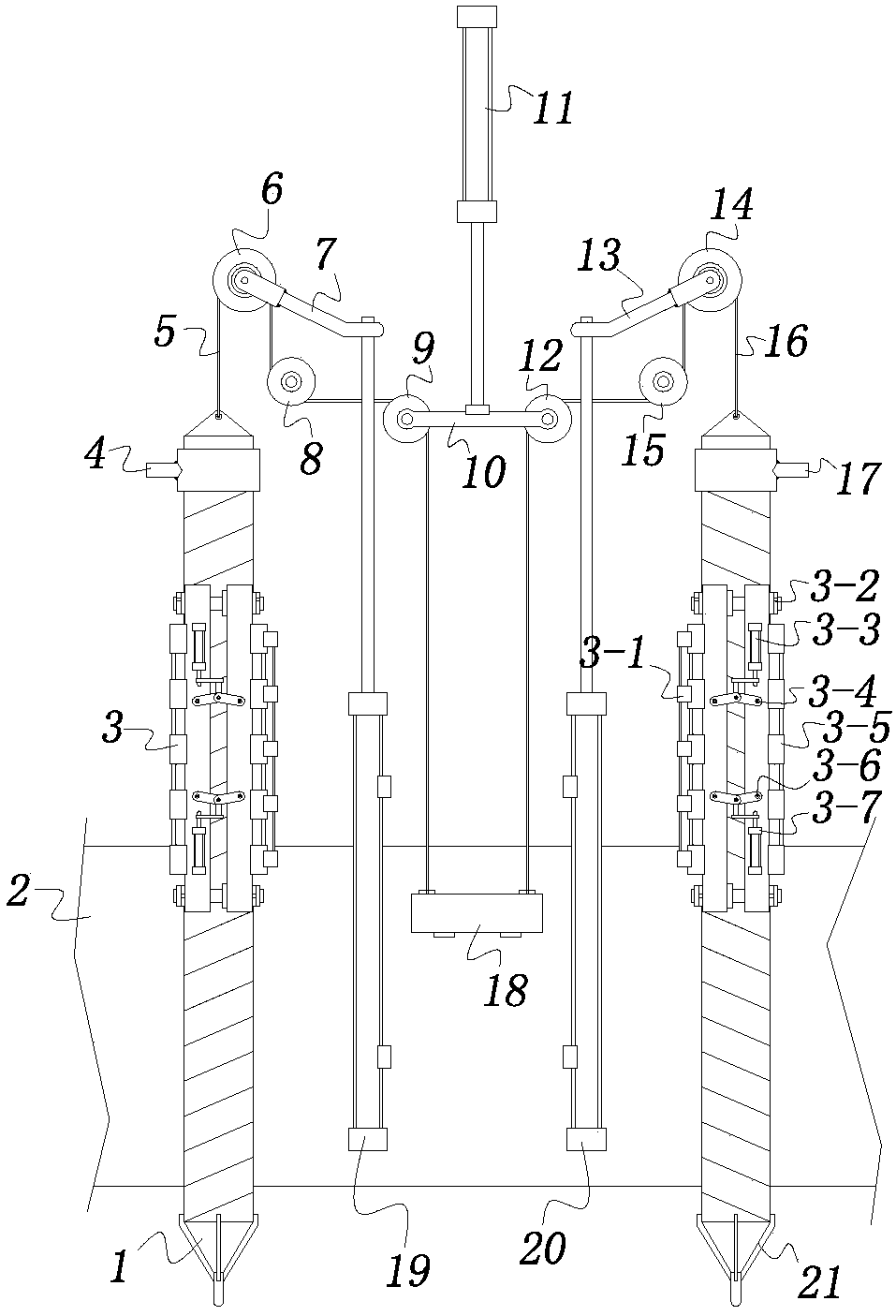

[0015] See figure 1 , the steel pile hoisting system of the cutter suction dredger of the present invention is installed and fixed on the connection base 18 on the hull 2, the first sling 5 and the second sling 16 are connected on the connection pedestal 18, on the connection pedestal A first jacking oil cylinder 19 and a second jacking oil cylinder 20 are installed and fixed on the left and right sides of 18 respectively.

[0016] On the hull 2, two opposing pile clamping devices 3 are also installed, the first steel pile 1 is arranged in the pile clamping device 3 on the left side, and the second steel pile 21 is arranged in the pile clamping device 3 on the right side , the pile clamping device 3 is used to fix the steel pile after the steel pile is hoisted or lowered.

[0017] The pile clamping device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com