Method and device for tenderizing and efficiently pickling beef by ultrasonic wave and pulsed electric field

A pulsed electric field and ultrasonic technology, used in food ultrasonic treatment, meat tenderization, and meat softening through electrical treatment, can solve the problems of beef loss of chewiness, difficult industrialization, and high power output requirements, and improve food safety. The effect of improving level, water retention and tenderness, and improving the efficiency of dishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

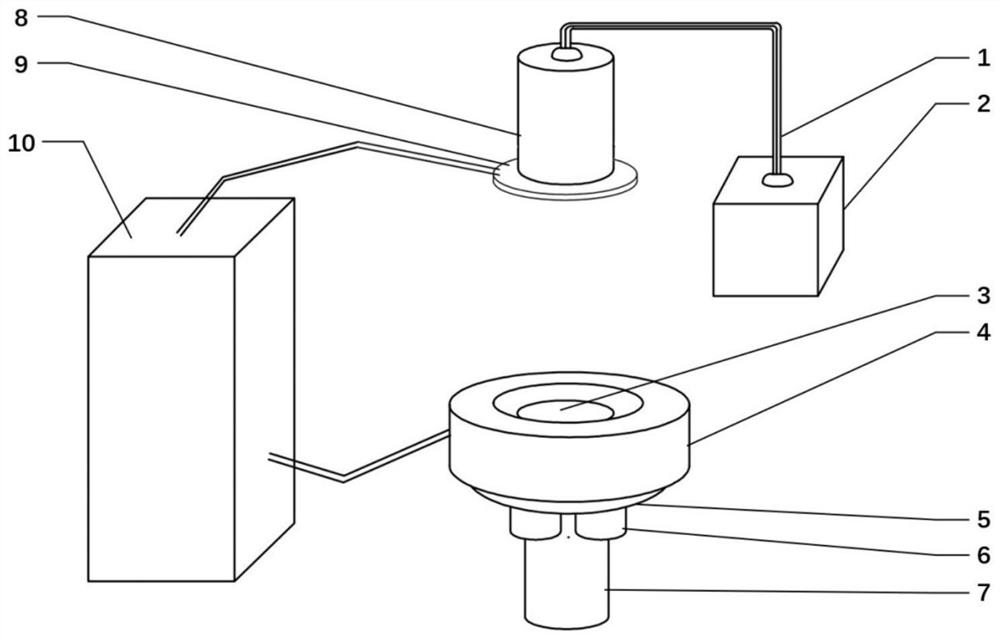

[0051] use figure 1 1 kg of Inner Mongolia Sanhe beef semitendinosus muscle was selected, frozen at -18°C for 2 hours, and cut into slices with a thickness of 1 cm, a width of 10 cm, and a length of 12 cm with a steak slicer (AIMEILI SL-518 type), weighing 120 g. Put it into the sterilized processing chamber 3; adjust the electrodes, fix the lower electrode plate 5, and after the meat slices are placed in the processing chamber 3, open the lifting device 1, and adjust the upper electrode plate 9 to completely stick the meat slices through the pressure sensing system 2. Closed position, electrode distance (distance between upper electrode plate 9 and lower electrode plate 5) is 0.95cm; Start ultrasonic generator 6, carry out ultrasonic treatment, adopt power density to be 0.3W / cm 2 Ultrasonic treatment for 3 minutes; start the pulse electric generator and controller 10, and carry out pulse electric field treatment, adopt the PEF-500 pulse electric field processor of Guangzhou P...

Embodiment 2

[0054] use figure 1 The device, select Angus beef semitendinosus, freeze at -18°C for 3 hours, use a steak slicer (AIMEILI SL-518 type) to cut into slices with a thickness of 1.5cm, a width of 6cm, and a length of 15cm, with a weight of 135g , put it into the sterilized processing chamber 3; adjust the electrodes, fix the lower electrode plate 5, and after the meat slices are placed in the processing chamber 3, open the lifting device 1, and through the pressure sensing system 2, the upper electrode plate 9 is automatically adjusted to completely fill the meat slices. The position of bonding, the electrode distance (the distance between the upper electrode plate 9 and the lower electrode plate 5) is 0.95cm; start the ultrasonic generator 6, carry out ultrasonic treatment, and adopt a power density of 0.5W / cm 2 Ultrasonic treatment for 5 minutes; start the pulse electric generator and controller 10, and carry out pulse electric field treatment, adopt the PEF-500 pulse electric ...

Embodiment 3

[0057] use figure 1 The longissimus muscle of the back of Inner Mongolia Sanhe cattle was selected, frozen at -18°C for 3 hours, and cut into slices with a thickness of 1 cm, a width of 8 cm, and a length of 15 cm with a steak slicer (AIMEILI SL-518 type), weighing 120 g. Put it into the sterilized processing chamber 3; adjust the electrodes, fix the lower electrode plate 5, and after the meat slices are placed in the processing chamber 3, open the lifting device 1, and through the pressure sensing system 2, the upper electrode plate 9 is automatically adjusted to completely stick the meat slices. Closed position, electrode distance (distance between upper electrode plate 9 and lower electrode plate 5) is 0.95cm; Start ultrasonic generator 6, carry out ultrasonic treatment, adopt power density to be 0.2W / cm 2Ultrasonic treatment for 2 minutes; start the pulse electric generator and controller 10, and carry out pulse electric field treatment, adopt the PEF-500 pulse electric fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com