Preparation method of oligomeric carboxylate chelating dispersant

A technology of chelating dispersant and oligomeric carboxylate, which is applied in the field of preparation of oligomeric carboxylate chelating dispersant, can solve the problems of rising production cost, high reaction temperature, long production cycle, etc., and achieve cost saving, The effect of low reaction temperature and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

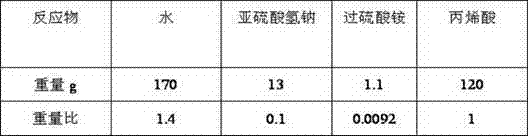

Embodiment 1

[0021] Reactant water sodium bisulfite Ammonium persulfate acrylic acid Weight g 165.8 14.43 1.28 120 weight ratio 1.4 0.12 0.01 1

[0022] Add 100g of water to a 500ml four-neck flask, add ammonium persulfate 0.64 (0.22% of the total amount of the system before neutralization), add 14.43g of sodium bisulfite (4.79% of the total amount of the system before neutralization), stir to dissolve, and control the temperature for 45 At -50°C, add an aqueous solution of 120g of industrial grade acrylic acid and 0.64g of ammonium persulfate (dissolved in 65.8g of water) dropwise simultaneously, and finish adding dropwise simultaneously within 50-60min. Keep warm for another 30 minutes, slowly add 40g of caustic soda, add about 65g of 45% NaOH to adjust the pH to 7-8, then press 8 parts of sodium polyacrylate, add 2 parts of ethylenediaminetetramethylenephosphonic acid, stir well, and adjust the pH to 7-8 with NaOH. After the pH is 6-8, add water to...

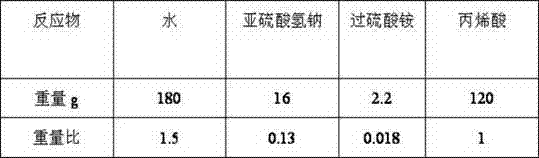

Embodiment 2

[0024] Reactant water Sodium metabisulfite sodium persulfate acrylic acid Weight g 186 20 1.6 120 weight ratio 1.6 0.17 0.013 1

[0025] In a 500ml three-neck flask, add 100g of water and 20g of sodium pyrosulfite and stir to dissolve, dissolve 1.6g of sodium persulfate in 86g of water and add to 120g of industrial grade acrylic acid, stir well and add to the dropping funnel to control the temperature at 30-40°C (no more than 40°C), 50-60 minutes to finish dripping, after dripping, control the material temperature to 35°C, keep warm for 1 hour, neutralize with about 180g of 40% sodium hydroxide solution, the temperature does not exceed 45°C, adjust the pH value to 7-8 , lower the temperature, add 7 parts of sodium polyacrylate and 3 parts of hydroxyethylidene diphosphonic acid, stir well, use NaOH to adjust the pH value to 6-8, add water to adjust the content to 40%, and then discharge to obtain the finished product. Measuring viscosity n...

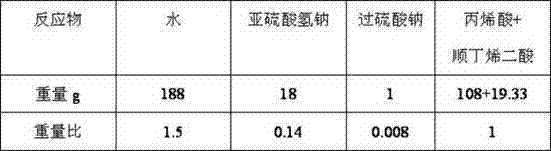

example 3

[0027]

[0028] Add 128g of water and 18g of sodium bisulfite to a 500ml three-neck flask, stir well, dissolve, control the temperature at 45-50°C, add dropwise a mixed solution of 108g (1.5mol) of acrylic acid and 19.33g (0.166mol) of maleic acid, and add dropwise Dissolve 1g of sodium persulfate in 60g of water or an aqueous solution, control the temperature at 30-50°C, drop it for about 1 hour, keep it warm for 1 hour, neutralize it with 45% sodium hydroxide aqueous solution to a pH value of 7-8, and press 7.5 parts of sodium polyacrylate Add 2.5 parts of diethylenetriaminepentamethylene phosphonic acid and stir evenly, adjust the pH to 6-8 with NaOH, then adjust the solid content to 40% with water, discharge the finished product, measure the viscosity n 25 169mPa.s (No. 2 rotor, speed 60r.p.m, range 10-90%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com