Ammonia oxidation catalyst for internal combustion engine tail gas purification system and preparation method thereof

A tail gas purification and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of low ammonia conversion efficiency of catalysts, ammonia purification performance needs to be improved, lack of ammonia oxidation catalysts, etc., to achieve The effect of high selectivity, convenient operation and wide choice of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

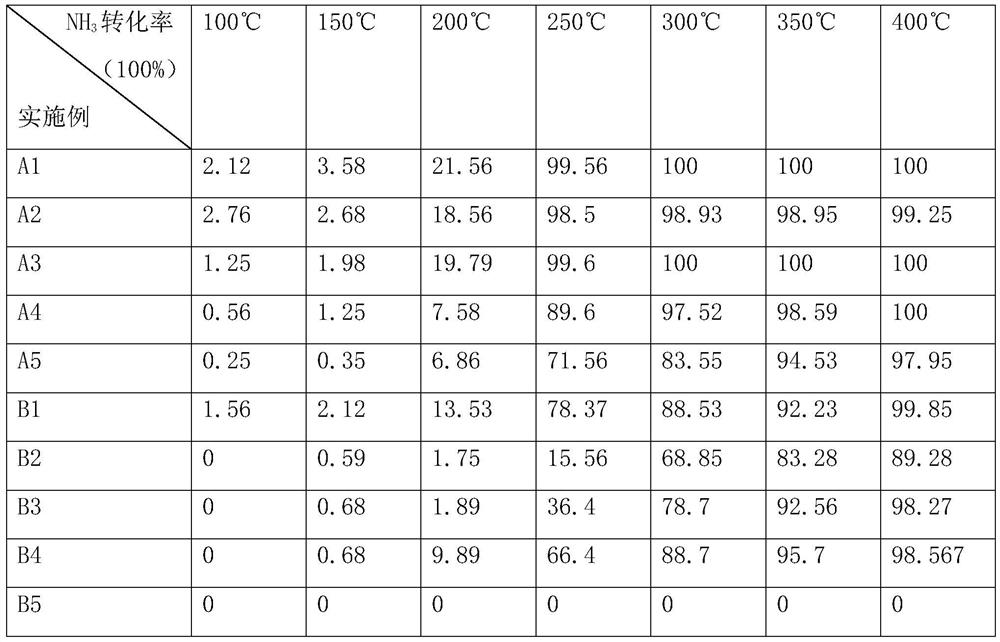

Examples

Embodiment 1

[0046] The preparation of embodiment 1 copper-based and platinum-based bimetallic catalyst

[0047] (1) Weigh 66 grams of ammonium sulfate to prepare 2.0 L of 0.5 mol / L solution. Weigh 200 grams of the self-made SSZ-13 molecular sieve required by the present invention, add it to the ammonium sulfate solution, put it in a water bath at 80 degrees Celsius, let it stand overnight at a constant temperature, then pour out the supernatant, and wash and dry the solid with hot water. In the muffle furnace, the temperature was raised to 540 degrees Celsius at a rate of 1 degree Celsius per minute, kept for 2 hours, and cooled to obtain a hydrogen-type SSZ-13 molecular sieve.

[0048] (2) Weigh 5 grams of the SSZ-13 molecular sieve obtained in step (1), add deionized water dropwise until the molecular sieve is wetted, the measured water absorption is 3 grams, and the calculated water absorption is 0.6.

[0049] (3) Calculate the water absorption of 9.4 grams of SSZ-13 molecular sieves ...

Embodiment 2

[0051] The preparation of embodiment 2 copper-based and platinum-based bimetallic catalysts

[0052] This implementation only describes the differences from Embodiment 1.

[0053] Calculate the water absorption of 9.46 grams of SSZ-13 molecular sieve according to the water absorption of step (2) SSZ-13 molecular sieve of step embodiment 1, 1.698 grams of copper nitrate and 0.9 gram of platinum nitrate are dissolved in the above-mentioned water absorption together, it is dropwise Add to 9.62 grams of SSZ-13 molecular sieve obtained in step (1), fully stir and mix evenly, after drying at 80 degrees Celsius, place in a muffle furnace, heat up to 540 degrees Celsius at a rate of 1 degree Celsius per minute, and roast at a constant temperature After 2 hours, cool to room temperature to obtain copper-supported and Pt-supported bimetallic ammoxidation catalyst samples, labeled as catalyst A2. The copper loading weight ratio of the catalyst was 4.5%, and the Pt loading weight ratio w...

Embodiment 3

[0054] The preparation of embodiment 3 copper-based and platinum-based bimetallic catalysts

[0055] This implementation only describes the differences from Embodiment 1.

[0056] Calculate the water absorption of 9.55 grams of SSZ-13 molecular sieve according to the water absorption of step (2) SSZ-13 molecular sieve of step embodiment 1, 1.51 grams of copper nitrate and 0.5 gram of platinum nitrate are dissolved in the above-mentioned water absorption together, it is dropwise Add to 9.65 grams of SSZ-13 molecular sieve obtained in step (1), fully stir and mix evenly, after drying at 80 degrees Celsius, place in a muffle furnace, heat up to 540 degrees Celsius at a rate of 1 degree Celsius per minute, and roast at a constant temperature After cooling to room temperature for 2 hours, a copper-supported and Pt-supported bimetallic ammoxidation catalyst sample was obtained, labeled as catalyst A3. The copper loading weight ratio of the catalyst was 4%, and the Pt loading weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com