A hot press forming apparatus and a method for hot press forming a blank

A technology of hot press forming and press forming, which is applied in the field of hot press forming of billets, can solve the problems of damaging the quality of metal parts and the process of hot press forming of metal parts, and achieve the effect of enhancing the positive technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

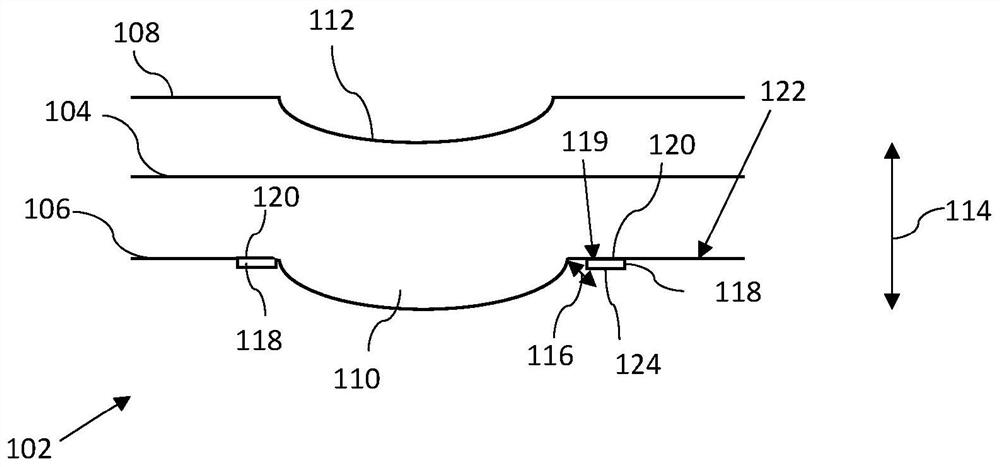

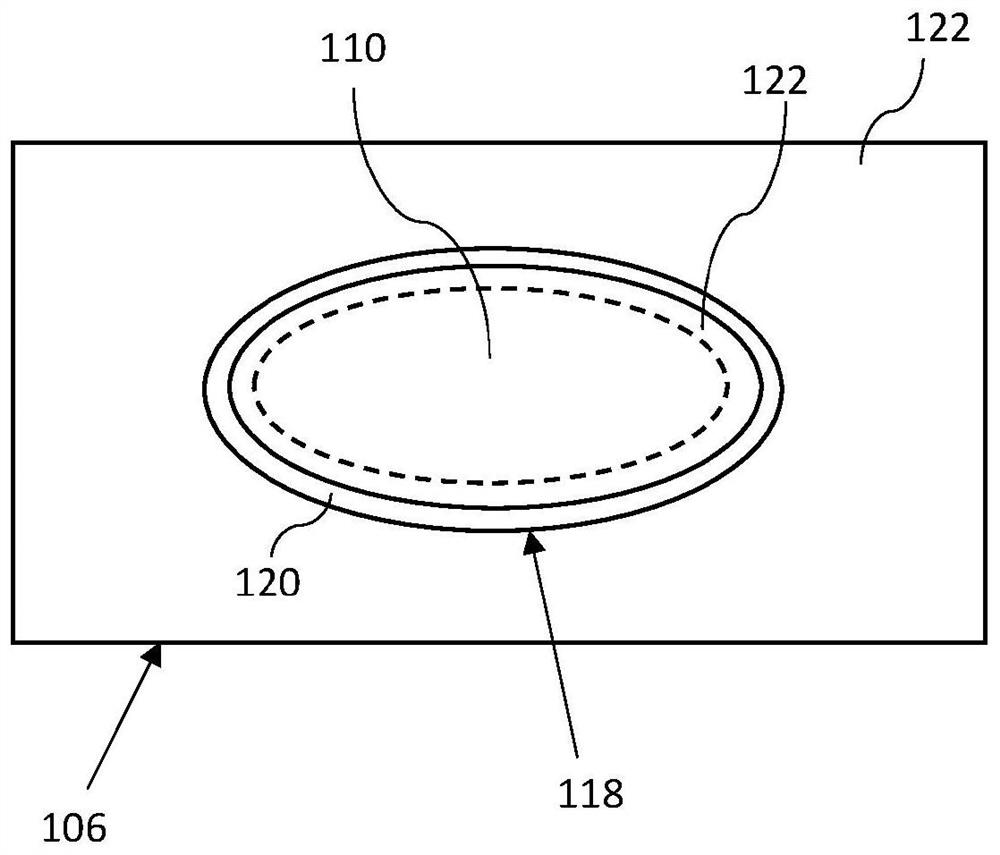

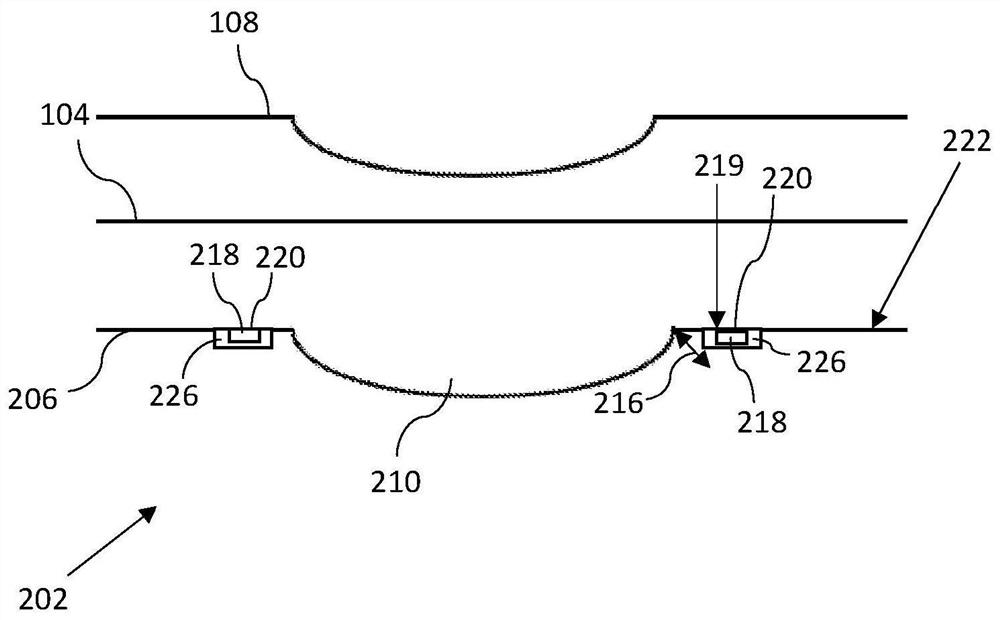

[0036] refer to figure 1 and figure 2 , a hot press forming apparatus 102 for forming a blank 104 is provided. Blank 104 may include or consist of a metal or metal alloy. The blank 104 may include or consist of aluminum or a metal alloy including aluminum. The blank 104 may be a sheet of material, such as a sheet comprising or consisting of a metal or metal alloy. Thermocompression forming apparatus 102 includes a first die 106 and a second die 108 . The first mold 106 has at least one mold cavity 110 surrounded by the remainder of the first mold 106 . The second mold 108 has at least one mold protrusion 112 . The mold protrusion 112 of the second mold 108 is complementary to the mold cavity 110 of the first mold 106 . The first mold 106 may be referred to as a female mold and the second mold 108 may be referred to as a male mold. Each of the first mold 106 and the second mold 108 may include or consist of a metal or metal alloy. exist figure 1 and figure 2 In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com