Open-loop Hall current sensor

A Hall current and sensor technology, applied in the field of sensors, can solve the problems of easy breakage, many current sensors, and cumbersome assembly process, and achieve the effects of improving stability, increasing contact area, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

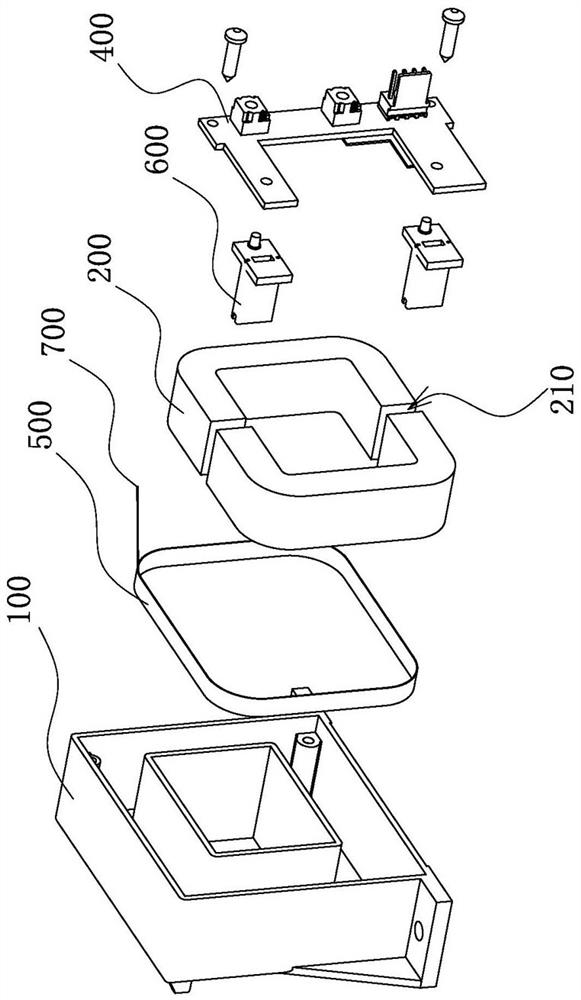

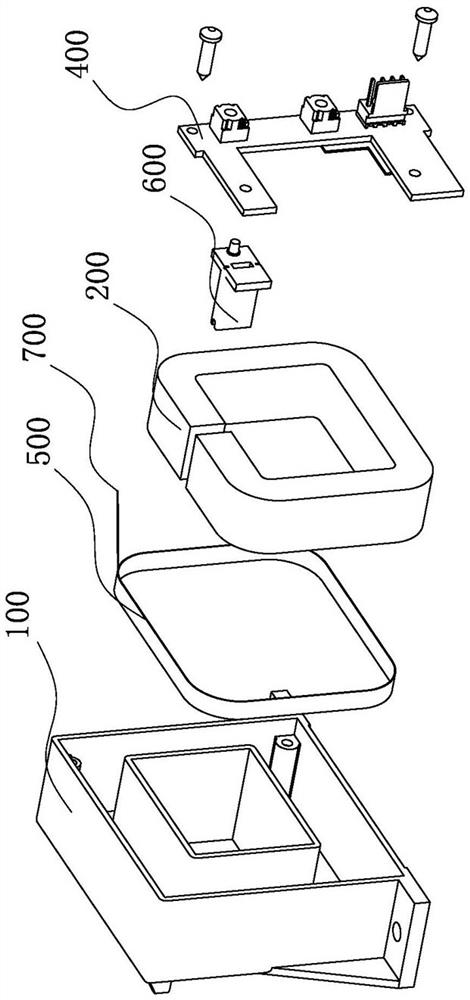

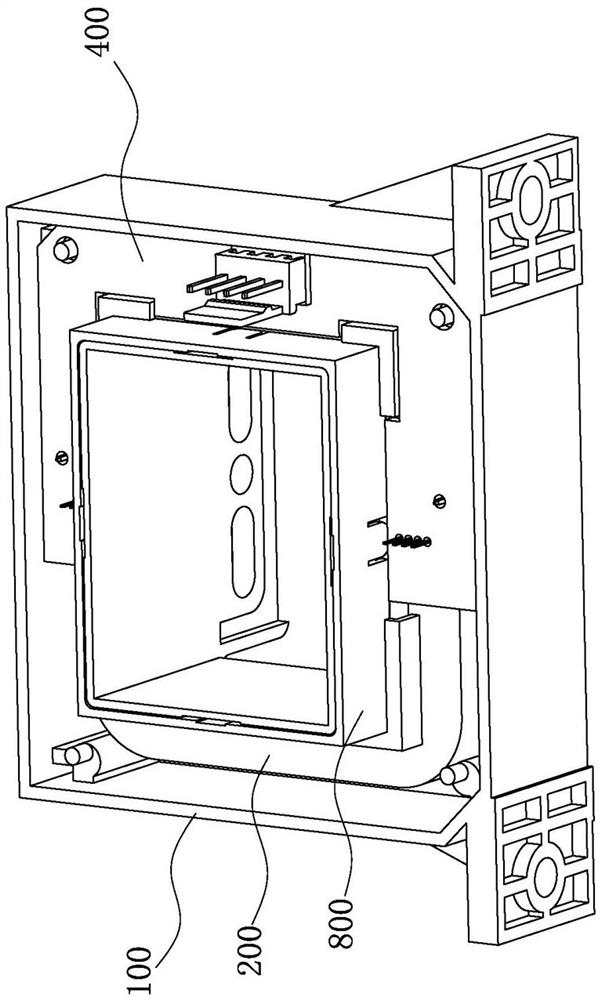

[0067] Such as Figure 3 to Figure 8 As shown, the difference between this embodiment and the first embodiment is that the iron core 200 in this embodiment is a whole, while the iron core 200 in the first embodiment is two oppositely arranged splits .

[0068] It should be noted that, in the present invention, descriptions involving "first", "second", "one" and so on are only for descriptive purposes, and should not be understood as indicating or implying their relative importance or implicitly indicating The number of technical characteristics. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of these features. In the description of the present invention, "plurality" means at least two, such as two, three, etc., unless otherwise specifically defined. The terms "connection" and "fixation" should be understood in a broad sense, for example, "fixation" can be a fixed connection, a detachable connection, or an integral body; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com