A box-type high-voltage power capacitor

A power capacitor and high-voltage technology, applied in capacitors, electrical components, etc., can solve problems such as high cost, environmental pollution, and low reliability, and achieve the effects of prolonging service life, improving reliability, and reducing operating temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

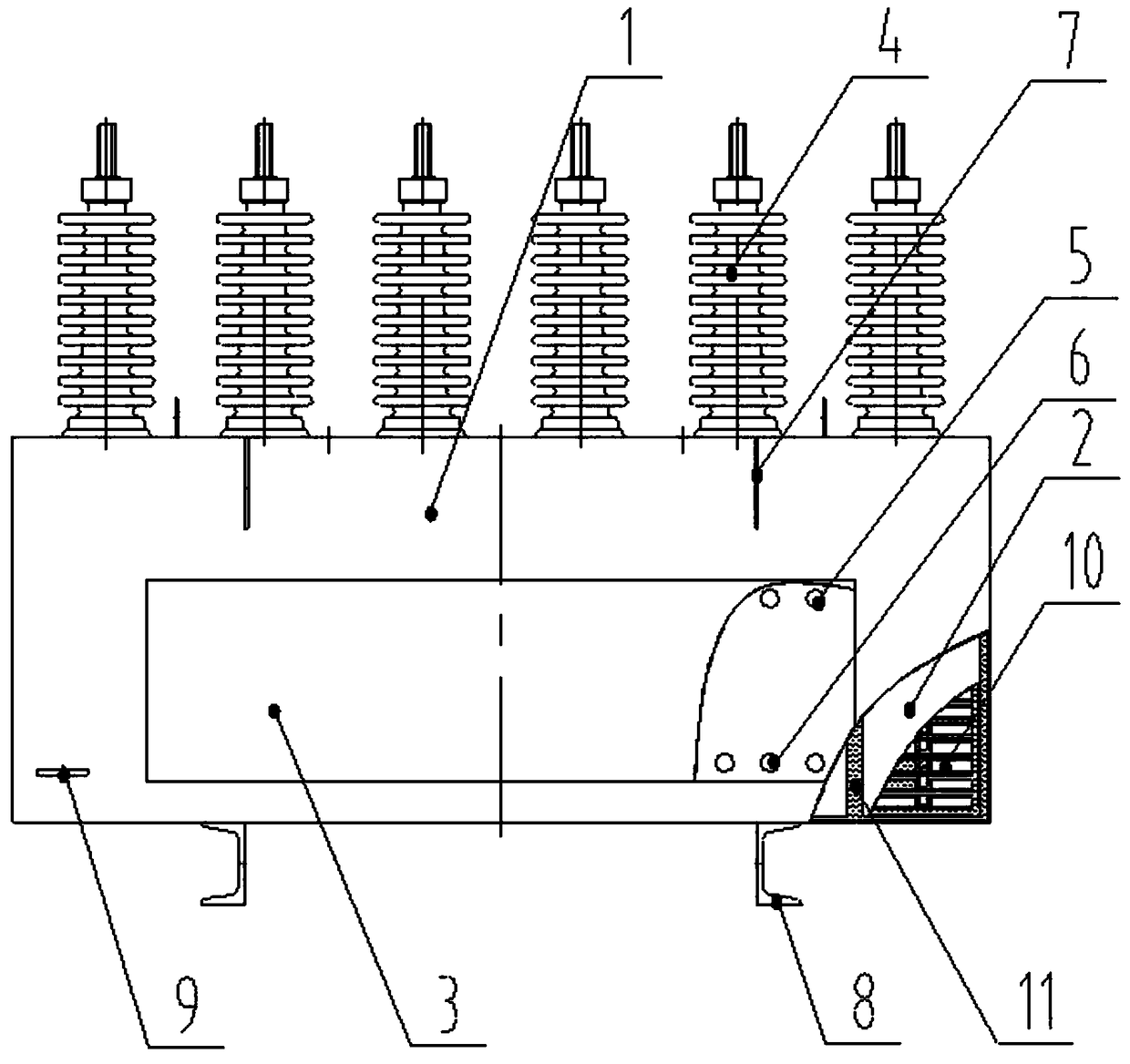

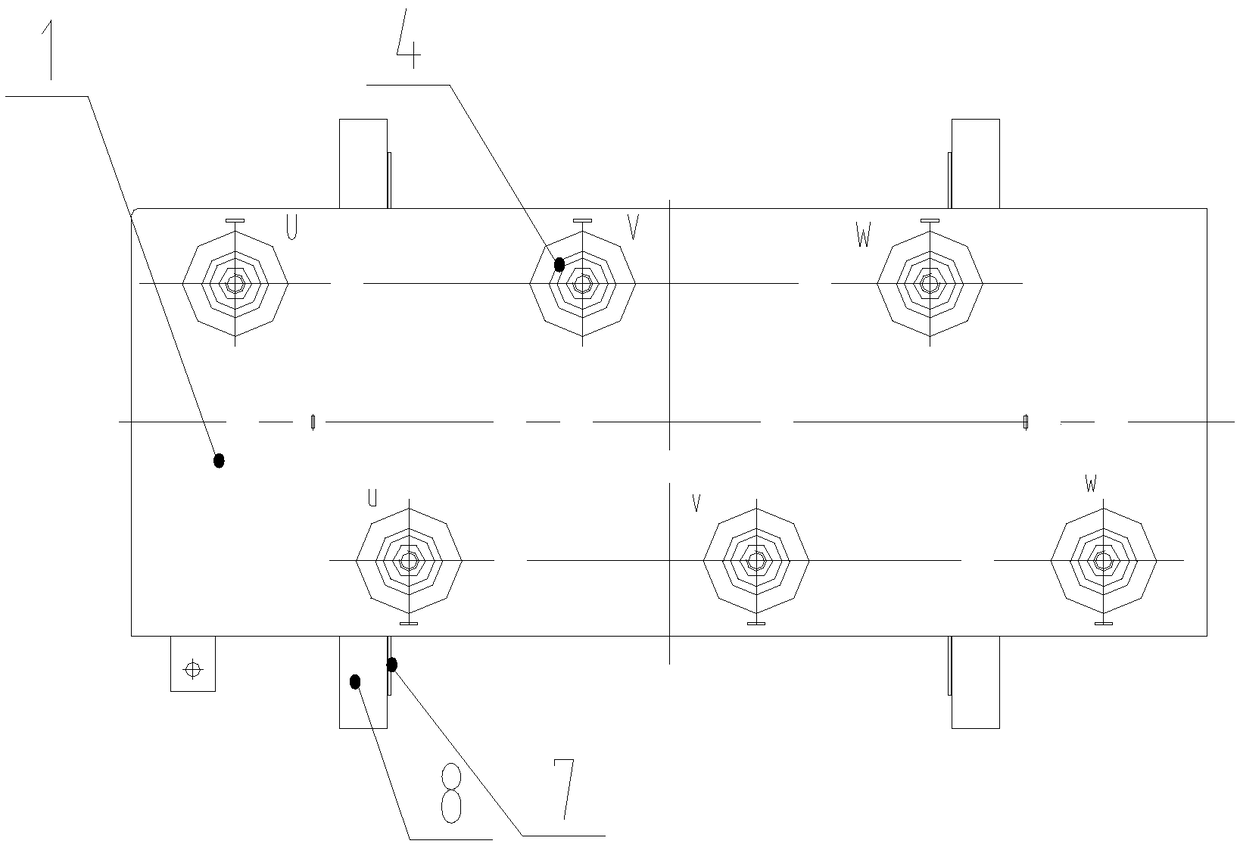

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0025] like figure 1 As shown, a box-type high-voltage power capacitor includes a casing 1 , a core 2 and a compensating cooling device 3 . The shell 1 is a hollow structure made of stainless steel plate. The state has stepped up environmental protection management, and ordinary steel plates are used on capacitors, which require pickling, alkali neutralization, and then phosphating and other surface treatments. The process is complicated and costly, causing pollution to the environment. Many provinces and cities prohibit the construction of such production lines . The use of stainless steel plate does not require the above surface treatment. Preferably: the shell 1 uses a 3mm thick stainless steel plate instead of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com