Secondary pressurization electro-hydraulic control system for rotary drilling rig and control method

An electro-hydraulic control system and two-stage pressurization technology, which are applied in the automatic control system of drilling, drilling equipment, earth-moving drilling, etc. problems, to achieve the effect of improving work efficiency, reliable action coordination, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

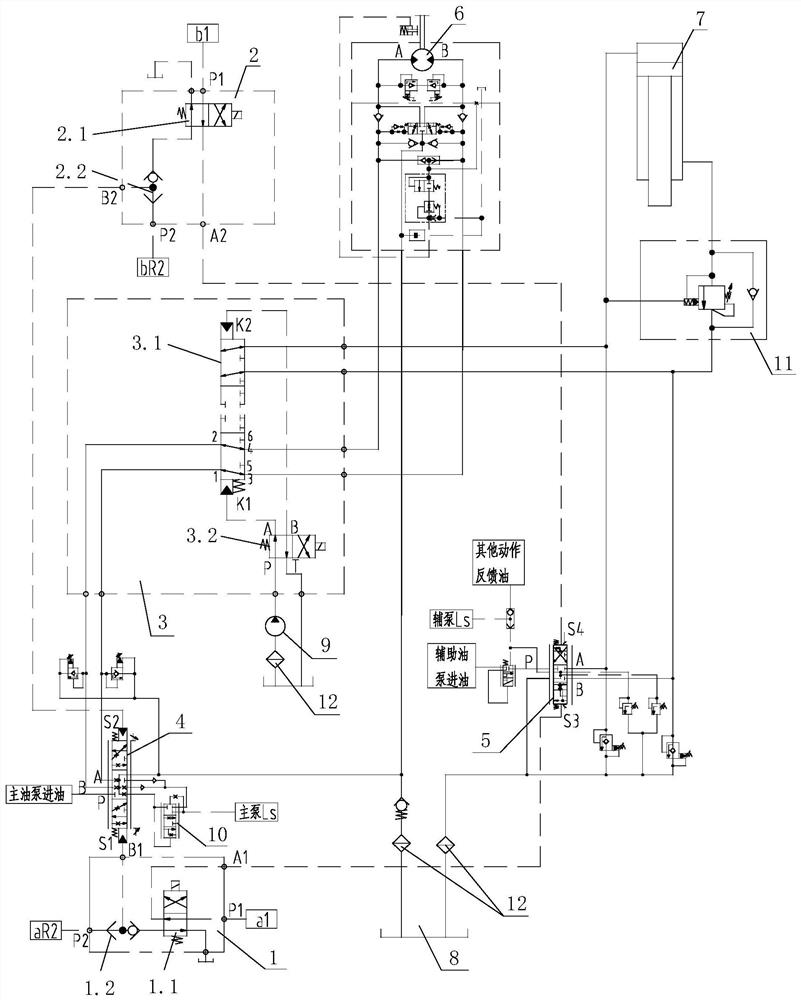

[0028] See figure 1, a two-stage pressurized electro-hydraulic control system for a rotary drilling rig in this embodiment, including a first pilot control valve 1, a second pilot control valve 2, a selector valve 3, a main valve auxiliary coil 4, an auxiliary valve pressurization 5. Auxiliary winch motor 6, pressurized oil cylinder 7, oil tank 8 and pilot pump 9. The specific structure is as follows:

[0029] The first oil inlet P1, the second working oil port P2, the first working oil port A1 and the second working oil port B1 of the first pilot control valve 1 are connected with the first pressurized handle control oil port a1 and the third pressurized oil port respectively. The handle control oil port b1, the first control end S3 of the auxiliary val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com