Mud pump piston rubber and preparation method thereof

A mud pump and piston technology, which is applied in the field of mud pump piston rubber and its preparation, can solve problems affecting the assembly of rubber and piston, affecting the normal use of the piston assembly, tearing and sealing, and avoiding impact cracks and gaps , reduce impact and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

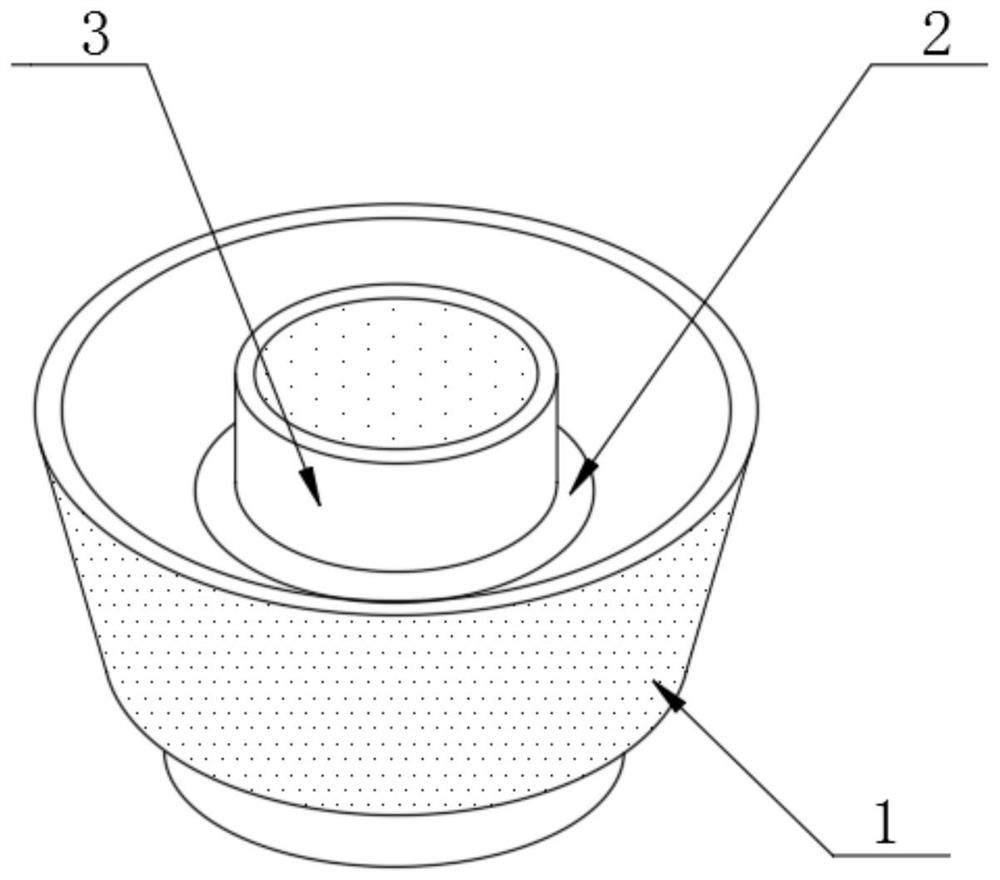

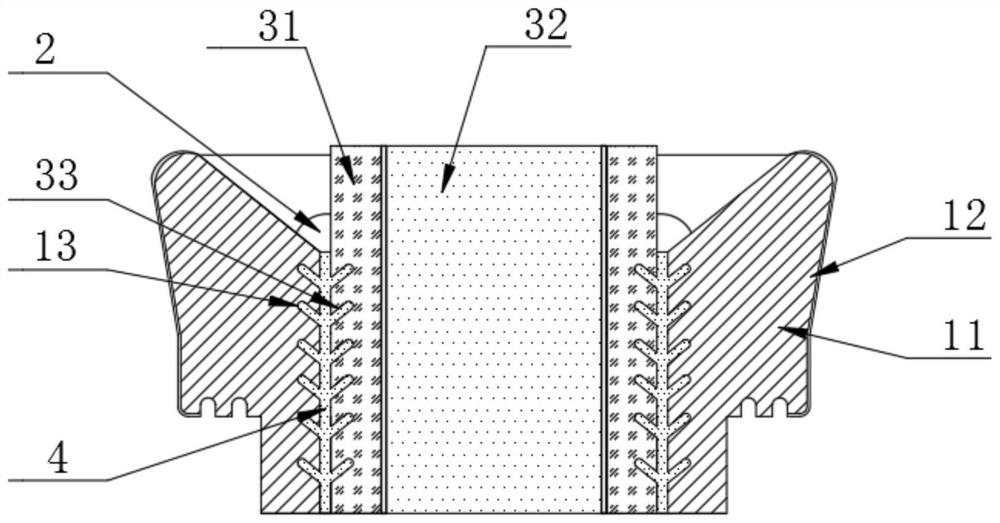

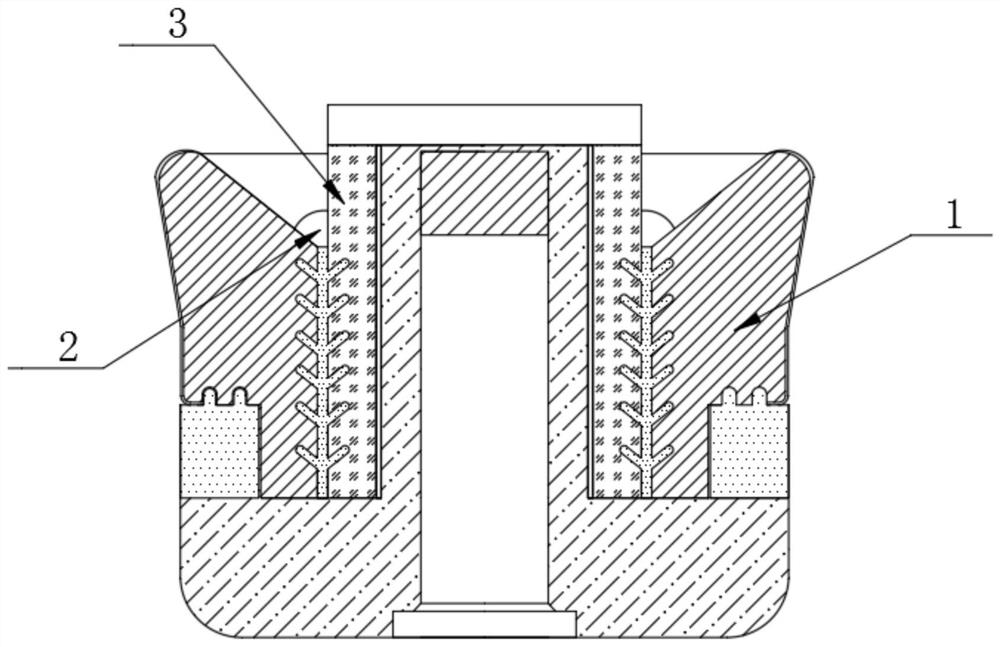

[0031] Such as Figure 1-3 As shown, a piston rubber of a mud pump includes an inner rubber column 3 sleeved on the outside of the piston and an outer rubber bowl 1 disposed outside the inner rubber column 3 and subjected to hot-press gluing. One side of the outer rubber bowl 1 is For the concave conical surface, one end of the inner rubber column 3 is set higher than the concave conical surface, and a sealing colloid 2 is provided between the outer side of the inner rubber column 3 and the concave conical surface.

[0032] The outer rubber bowl 1 and the inner rubber column 3 are respectively obtained according to a series of processing procedures such as banburying, mixing, molding, vulcanization molding, and demoulding, and then the two are bonded together by hot-pressing gluing. Finally, the finished rubber is made, the inner rubber column 3 is socketed corresponding to the piston core, and the outer rubber bowl 1 is installed correspondingly to the metal fixing frame on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com