Copper immersion method and device for tungsten sponge matrix

A tungsten sponge and substrate technology, applied in the field of microwave vacuum electronic devices, can solve the problems affecting cathode emission performance, evaporation performance and cathode life, and achieve the effects of improving emission performance, inhibiting evaporation, and reducing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

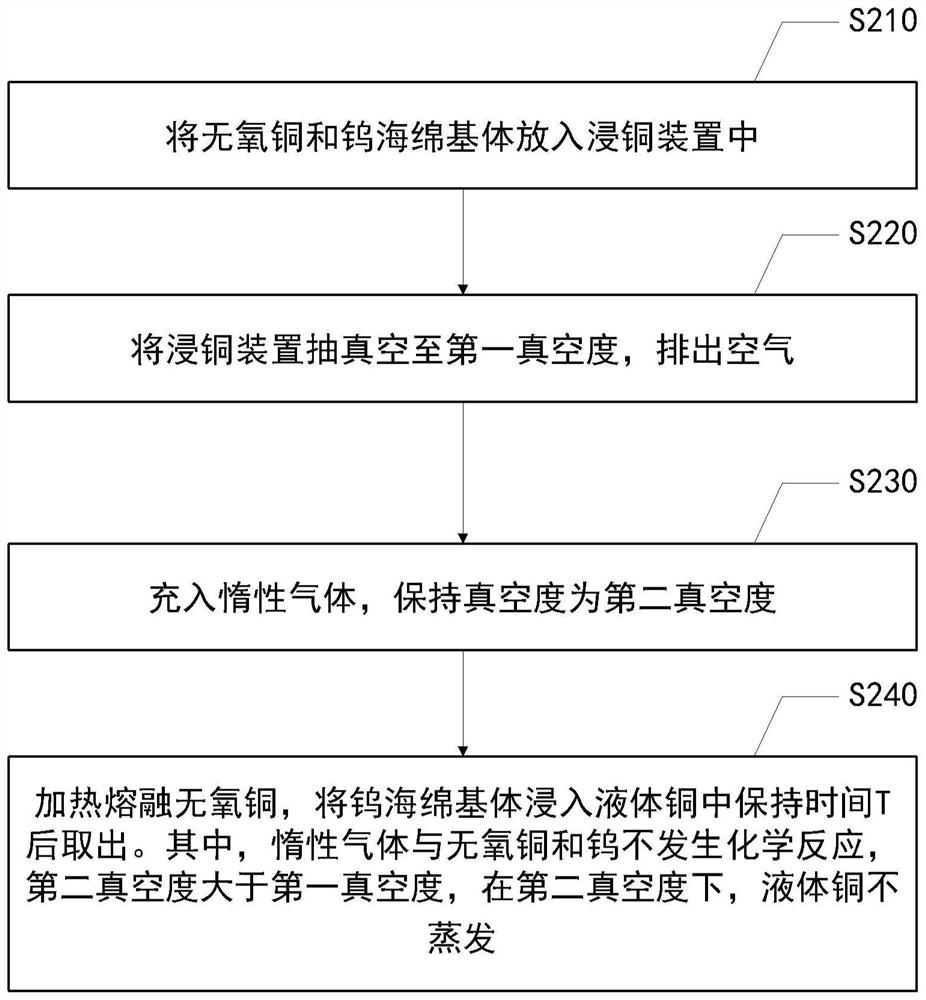

[0076] A tungsten sponge copper immersion method, the method for example comprises the following steps:

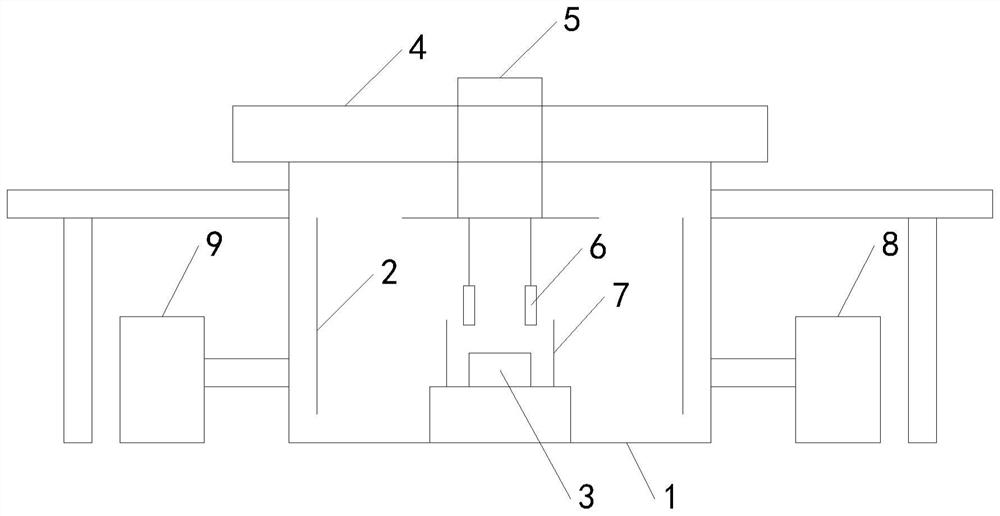

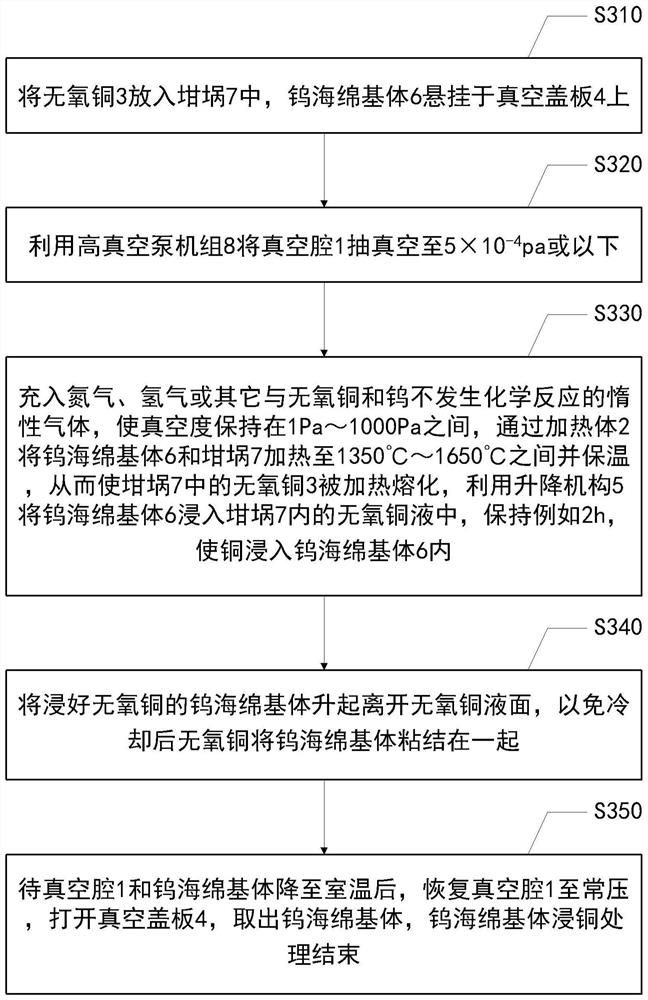

[0077] In step A, the oxygen-free copper 3 is put into the crucible 7 , and the tungsten sponge substrate 6 is suspended on the vacuum cover 4 .

[0078] Step B, use the high vacuum pump unit 8 to evacuate the vacuum chamber 1 to 5×10 Pa or below.

[0079] Step C, fill nitrogen, hydrogen or other inert gases that do not react chemically with oxygen-free copper and tungsten, keep the vacuum between 1Pa and 1000Pa, and heat the tungsten sponge substrate 6 and crucible 7 to 1550 through the heating body 2 ℃, so that the oxygen-free copper in the crucible is heated and melted, and the tungsten sponge matrix 6 is immersed in the oxygen-free copper liquid in the crucible 7 by the lifting mechanism 5, and kept warm for 5 hours, so that the copper is immersed in the tungsten sponge matrix.

[0080] In step D, the tungsten sponge substrate dipped in oxygen-free copper is lifted aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com