Application of transition metal carbonate nanomaterial in electrocatalytic reduction reaction of nitrate

A nanomaterial and transition metal technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve problems such as unsuitable large-scale industrial applications, catalytic activity and stability effects, toxic by-products, etc. The effect of low production cost and low reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

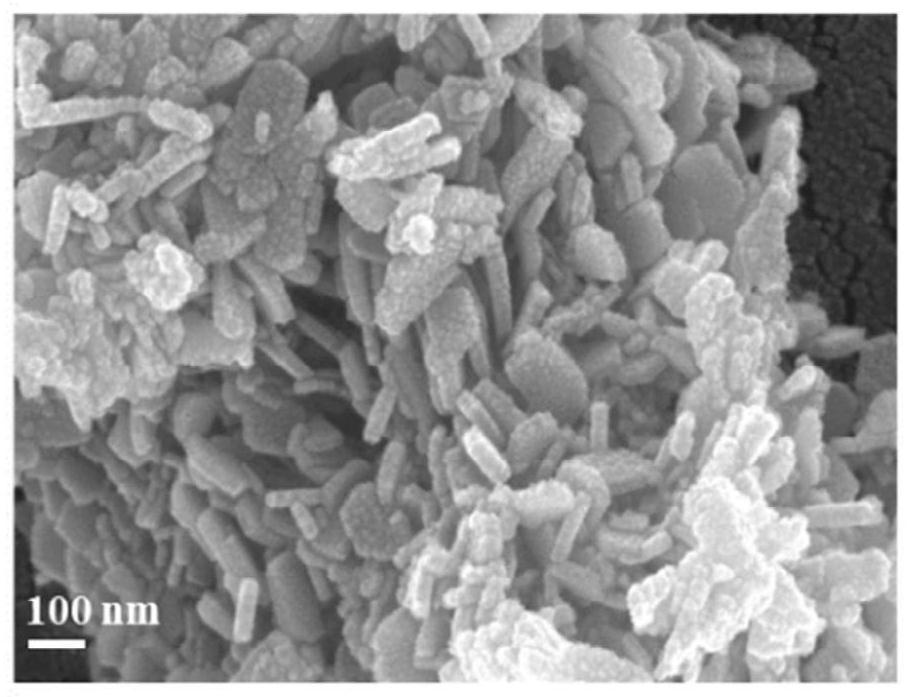

[0031] A transition metal carbonate nanomaterial Co@Cu 2 (OH) 2 CO 3 The preparation method comprises the following steps:

[0032] S1, dissolving copper salt and cobalt salt in water to obtain mixed solution A;

[0033] S2. Dissolving hydroxide and anhydrous carbonate in water to obtain a mixed solution B;

[0034] S3. Slowly add the mixed solution B obtained in step S2 to the mixed solution A obtained in step S1 under continuous stirring, transfer to a high-pressure reaction kettle, seal and place it in a box-type resistance furnace. The reaction was carried out for 10-48 hours, cooled to room temperature, washed and dried by centrifugation to obtain Co@Cu 2 (OH) 2 CO 3 .

[0035] Wherein, the cobalt salt is one or more of cobalt chloride, cobalt hydroxide, cobalt carbonate, cobalt acetate, cobalt sulfate; the copper salt is copper chloride, tungsten hydroxide, copper carbonate, copper acetate, One or more of copper sulfate and copper nitrate.

[0036] The consumption...

Embodiment 1~4

[0041] Embodiment 1~4 used raw material and consumption are as shown in table 1 below:

[0042] Table 1

[0043]

[0044] 1, the preparation method of the transition metal carbonate nanomaterial of embodiment 1~4 is:

[0045] Configure mixed solution A and mixed solution B according to the ratio shown in Table 1, slowly add mixed solution B to mixed solution A under constant stirring until the pH value reaches 8.2±0.2, continuously stir at room temperature for 1 hour, transfer to 50 ml autoclave was sealed and reacted at 80°C for 12 hours. After the reactor was cooled to room temperature, the product was collected by centrifugation, washed with water and ethanol at least three times, and dried overnight in an oven at 60°C to obtain the transition metal carbonate nanomaterials of Examples 1-4.

[0046] In order to facilitate the distinction, according to the ratio of the amount of copper to cobalt in Examples 1 to 4 of the present invention, the transition metal carbonate ...

Embodiment 5

[0054] Transition metal carbonate nanomaterial 3Co@Cu prepared with embodiment 1 2 (OH) 2 CO 3 As an example, for the preparation of an electrocatalytic reduction nitrate electrode, the specific steps are as follows:

[0055] Weigh 1mg 3Co@Cu 2 (OH) 2 CO 3 Mixed with acetylene black and polyvinylidene fluoride in N-methylpyrrolidone solution, where, 3Co@Cu 2 (OH) 2 CO 3 , acetylene black, and polyvinylidene fluoride in a mass ratio of 8:1:1 to obtain a catalyst slurry. After ultrasonication for one hour, absorb the catalyst slurry and apply it evenly on the pretreated hydrophilic carbon cloth. The effective area of the catalyst is controlled at 1cm 2 , arrange the catalyst-loaded carbon in a vacuum drying oven, and dry at 80° C. overnight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com